Efficient nanocrystal colloidal hydrogen production catalyst and preparation method thereof

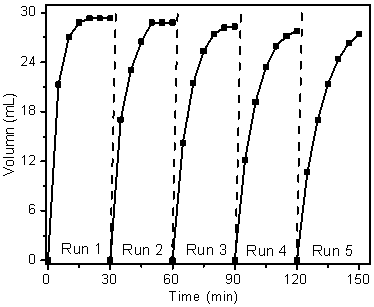

A technology of nanocrystals and catalysts, which is applied in the field of high-efficiency nanocrystal colloidal hydrogen production catalysts and its preparation, can solve problems such as easy agglomeration of transition metal materials and low catalytic activity, affecting the cycle life of noble metal catalysts, and low catalytic hydrogen production activity. To achieve the effect of multiple utilization, high-efficiency catalytic hydrogen production, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

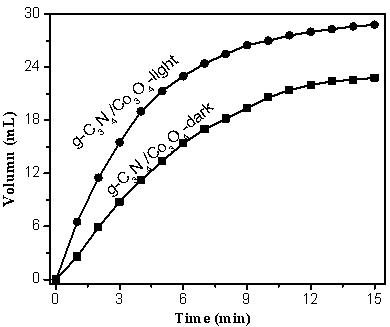

[0025] A preparation method for high-efficiency nanocrystalline colloidal hydrogen production catalysis, the technical scheme is: under certain temperature conditions, according to a certain proportion of cobalt dichloride solution, g-C 3 N 4 Powder ultrasonic dispersion solution and PVP colloidal solution are mixed, and then prepared by hydrothermal synthesis to obtain g-C 3 N 4 / Co 3 o 4 A nanocrystalline colloidal material with photoresponse enhanced catalytic hydrogen production performance; specifically comprising the following steps:

[0026] Step (1): Using melamine as raw material, prepare g-C by calcining method 3 N 4 Lumps, and then by grinding to get g-C 3 N 4 powder.

[0027] Step (2): Dissolve 0.00157 g-0.00314 g of cobalt dichloride in 20 mL of deionized water and stir well.

[0028] Step (3): Take 60 mg g-C 3 N 4 The powder was dissolved in 20 mL of deionized water, stirred evenly, mixed evenly with the solution obtained in step (2) and sonicated for ...

Embodiment

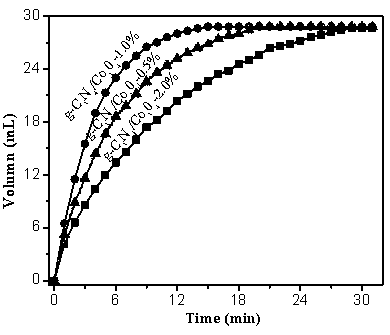

[0035] Comparative experiments of colloidal catalysts with different metal ion doping amounts:

[0036] First, prepare colloidal catalysts with different metal ion doping amounts:

[0037] This embodiment prepares g-C 3 N 4 / Co 3 o 4 The photoresponsive colloidal catalyst specifically comprises the following steps:

[0038] Step (1): Using melamine as raw material, prepare g-C by calcining method 3 N 4 Lumps, and then by grinding to get g-C 3 N 4 powder.

[0039] Step (2): Dissolve 0.00157, 0.00314 and 0.00628 g of cobalt dichloride in three 20 mL deionized water respectively and stir evenly.

[0040] Step (3): Take 3 portions of 60 mg g-C respectively 3 N 4 The powders were dissolved in 20 mL of deionized water, stirred evenly, mixed with the solution obtained in step (2) and ultrasonicated for 1 h.

[0041] Step (4): 3.96 g of protective agent polyvinylpyrrolidone (PVP) was dissolved in 20 mL of deionized water, and mixed with the mixed solution obtained in step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com