Ultraviolet-visible-near infrared responded PbS/TiO2 nanotube aggregation microsphere heterostructure as well as preparation method and application thereof

A technology of near-infrared photoresponse and near-infrared light, applied in chemical instruments and methods, hydrogen production, chemical/physical processes, etc. Form a tight combination and other issues to achieve the effects of good light absorption performance, low cost, low energy consumption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

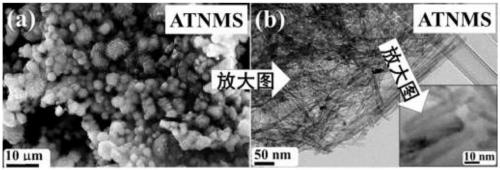

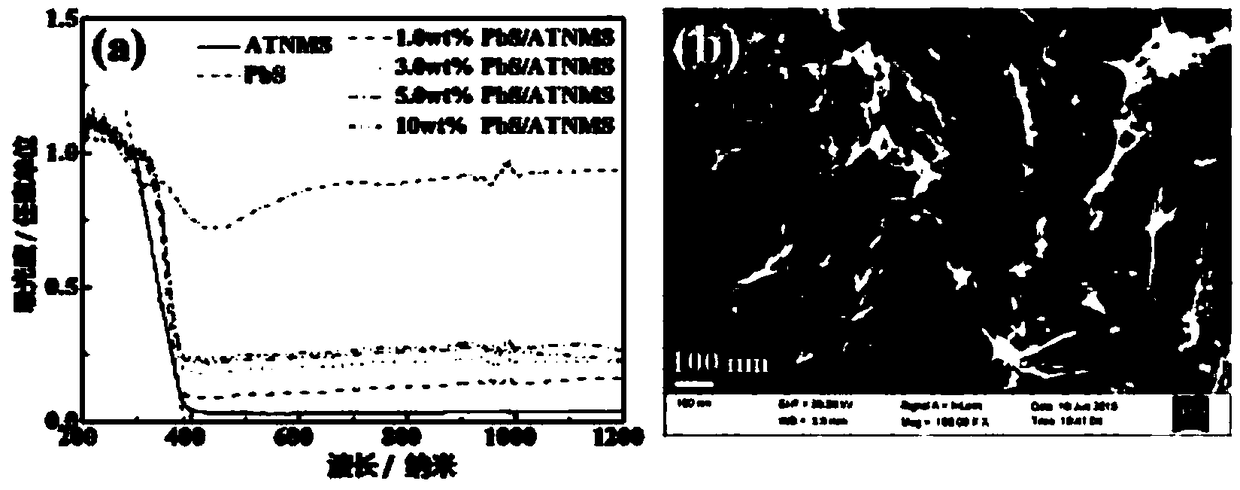

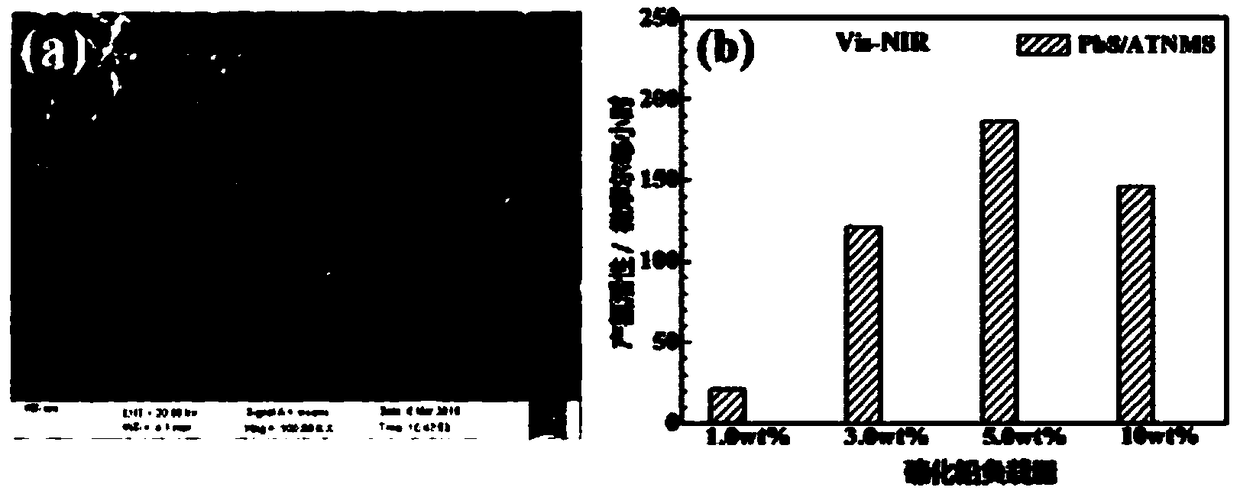

[0042] 8.0 mL of H 2 o 2 The solution was added dropwise to 60mL of NaOH solution, and then 0.5g of TiO 2 Nano-powder, after stirring for 30min, transfer the suspension to a 85mL reaction kettle, and heat at 160°C for 2h. The hydrothermal product was washed three times with deionized water and ethanol respectively, and then 100 mL of HCl solution was added for ion exchange for 12 hours. After centrifugation, it was washed again with water and absolute ethanol respectively. After drying, it was calcined at 500°C for 3h in the air to obtain ATNMS.

[0043] Add 0.1 g of the above ATNMS to 100 mL of water and stir for 5 min to prepare a suspension. Add 7.5 mg of cysteine to the suspension and adjust the pH of the solution to 4, continue stirring for 1 h, then add 0.02 mL of Pb(NO 3 ) 2 solution, after stirring for 30 min, the product was collected by rotary evaporation. The collected samples were calcined at 500 °C for 3 h in an Ar atmosphere to obtain a PbS / ATNMS heteroju...

Embodiment 2

[0047] 8.0 mL of H 2 o 2 The solution was added dropwise to 60mL of NaOH solution, and then 0.5g of TiO 2 Nano-powder, after stirring for 30min, transfer the suspension to a 85mL reaction kettle, and heat at 160°C for 2h. The hydrothermal product was washed three times with deionized water and ethanol respectively, and then 100 mL of HCl solution was added for ion exchange for 12 hours. After centrifugation, it was washed again with water and absolute ethanol respectively. After drying, it was calcined at 500°C for 3h in the air to obtain ATNMS.

[0048] Add 0.1 g of the above ATNMS to 100 mL of water and stir for 5 min to prepare a suspension. Add 7.5 mg of cysteine to the suspension and adjust the pH of the solution to 4, continue to stir for 1 h, then add 0.06 mL of Pb(NO 3 ) 2 solution, after stirring for 30 min, the product was collected by rotary evaporation. The collected samples were calcined at 500°C for 3 h in an Ar atmosphere to obtain a PbS / ATNMS heterojunc...

Embodiment 3

[0052] 8.0 mL of H 2 o 2 The solution was added dropwise to 60mL of NaOH solution, and then 0.5g of TiO 2 Nano-powder, after stirring for 30min, transfer the suspension to a 85mL reaction kettle, and heat at 160°C for 2h. The hydrothermal product was washed three times with deionized water and ethanol respectively, and then 100 mL of HCl solution was added for ion exchange for 12 hours. After centrifugation, it was washed again with water and absolute ethanol respectively. After drying, it was calcined at 500°C for 3h in the air to obtain ATNMS.

[0053] Add 0.1 g of the above ATNMS to 100 mL of water and stir for 5 min to prepare a suspension. Add 7.5 mg of cysteine to the suspension and adjust the pH of the solution to 4, continue stirring for 1 h, then add 0.10 mL of Pb(NO 3 ) 2 solution, after stirring for 30 min, the product was collected by rotary evaporation. The collected samples were calcined at 500°C for 3 h in an Ar atmosphere to obtain a PbS / ATNMS heterojun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com