High-efficiency hydrogen-production ZnO core-shell nanorod array photocatalyst, preparation method and application thereof

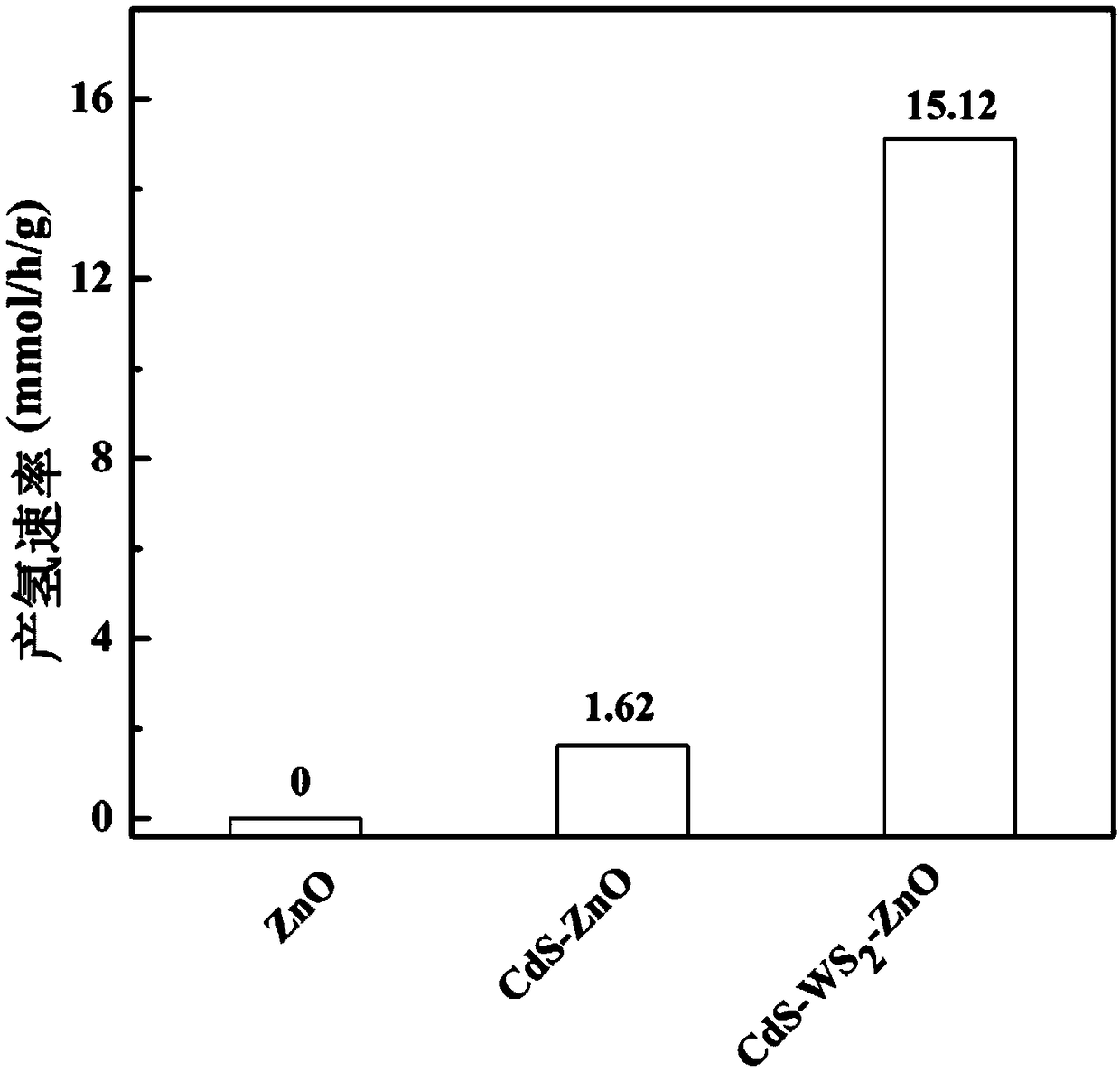

A nanorod array and photocatalyst technology, applied in the field of photocatalytic materials, can solve the problems of ZnO narrow light absorption range and low sunlight utilization rate, and achieve the effect of improving the hydrogen production activity of visible light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

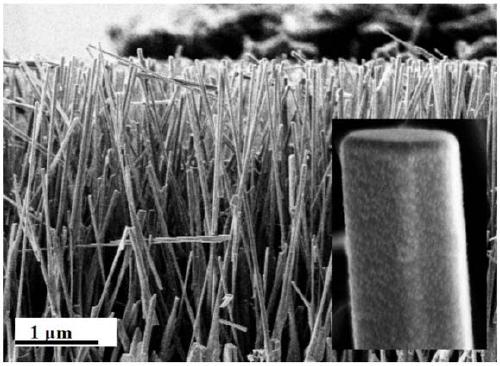

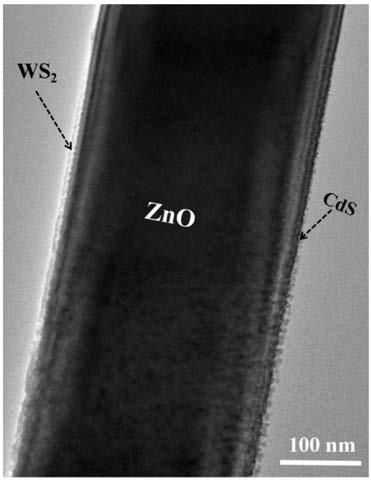

[0025] Example 1: The first step: ZnO powder and carbon powder with a purity of 99.99% are mixed and ground according to a mass ratio of 1:1, and filled into a ceramic boat; the sapphire substrate is cut into 1.5cm×1cm, followed by acetone , anhydrous ethanol, deionized water ultrasonic cleaning, and blow dry with nitrogen, as the growth substrate, and then put the closed end of a quartz tube with a length of 30 cm and a diameter of 3 cm, and place the cleaned sapphire substrate at a position 5 cm away from the tube mouth inside the quartz tube. Push the quartz tube as a whole into a horizontal tube furnace with a set temperature of 1050°C, close the tube furnace, evacuate, and feed argon gas flow rate of 150 sccm and oxygen flow rate of 15 sccm. After 30 minutes of reaction, ZnO nanorod arrays grow on sapphire surface;

[0026] The second step: using a magnetron sputtering apparatus to sputter a layer of WS in the ZnO nanorod array 2 thin film, with WS 2 The target materia...

Embodiment 2

[0029] Example 2: The method is the same as Example 1, except that the high temperature reaction time of the first step is 10 minutes, the sputtering time of the second step is 10 minutes, and the sputtering time of the third step is 10 minutes, and the obtained ZnO-WS 2 - The morphology of the CdS core-shell nanorod array is similar to that of Example 1.

Embodiment 3

[0030] Embodiment 3: The method is the same as in Embodiment 1, except that the high temperature reaction time of the first step is 15min, the sputtering time of the second step is 8min, the cavity volume is 1.5Pa, and the sputtering time of the third step is 15min, The cavity pressure is 1.5Pa, and the obtained ZnO-WS 2 - The morphology of the CdS core-shell nanorod array is similar to that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com