Production method of yellow rice wine

A production method and a technology for yellow rice wine, applied in the production field of yellow rice wine, can solve the problems of bitter taste of wine, easy to produce rancidity, complicated production process and operation of rice-fed rice wine, etc., and achieve the effect of simple production process operation and less rancidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

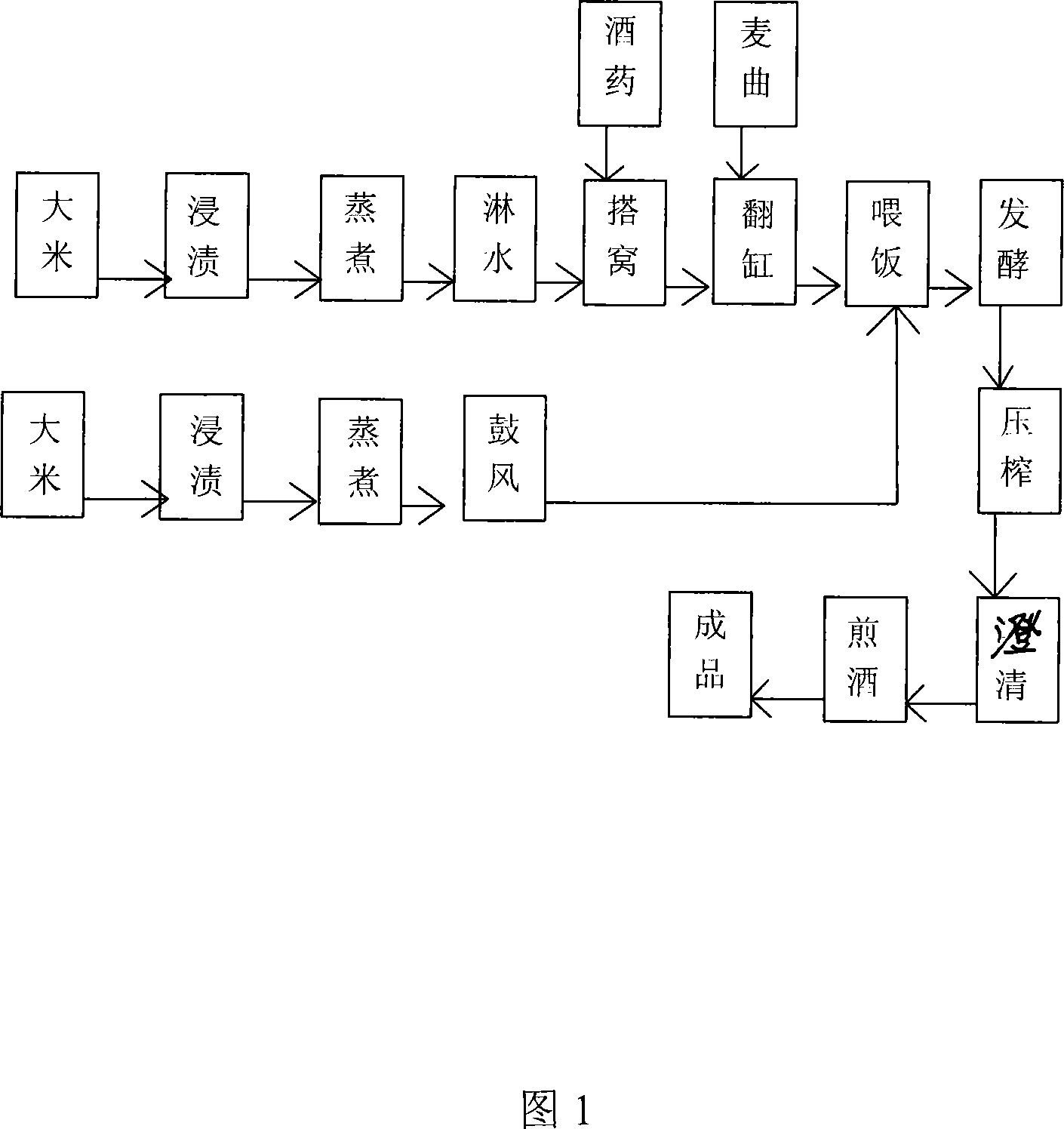

[0010] Embodiment 1 According to the production process block diagram that Fig. 1 provides, the concrete process flow of the present invention is: 1) dipping, 60 kilograms of rices are placed in water and dipped, and the dipping time is about 3 days; 2) cooking, soaking the rice The rice is sent to be steamed until it is cooked into rice, and the cooking time is about 10 minutes; 3) Make a nest, send the cooked rice to pour water, then mix with wine and medicine, put it in the brewing tank, and make a nest shape, place it for 48-60 hours, until the brewing liquid is full of nests, that is, the pool is full, and the rice layer turns jade-colored; 4) Turn over the tank, divide the rice and brewing liquid in the brewing tank into two, and divide it into two tanks; 5. ) fermentation, on the second day after turning over the tank, add water, wheat koji and rice to the tank for pre-fermentation. The amount of water and wheat koji is 120 kg and 5 kg respectively; the amount of rice f...

Embodiment 2

[0012] Embodiment 2 According to the production process block diagram that Fig. 1 provides, another specific process flow of the present invention is: 1) dipping, 60 kilograms of rice are placed in water and dipped, and the dipping time is about 4 days; 2) steaming, soaking The rice is sent to be steamed until it is cooked into rice, and the cooking time is about 12 minutes; 3) Make a nest, send the cooked rice to pour water, then mix with wine medicine, put it into the brewing tank, and build a Nest shape, place for 48-60 hours, until the brewing liquid is full of the nest, that is, the pool is full, and the rice layer turns to jade color; 4) Turn over the tank, divide the rice and brewing liquid in the brewing tank into two, and divide it into two tanks; 5) Fermentation. On the second day after turning over the vat, add water, wheat koji and rice to the vat for pre-fermentation. The amount of water and wheat koji is 120 kg and 5 kg respectively; the amount of rice fed is equ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com