Cavity mould component

A cavity mold and component technology, which is applied in the field preparation of formwork/formwork/work frame, building components, building construction, etc., can solve the problems of low production efficiency, inconvenient assembly line production, inconvenient production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

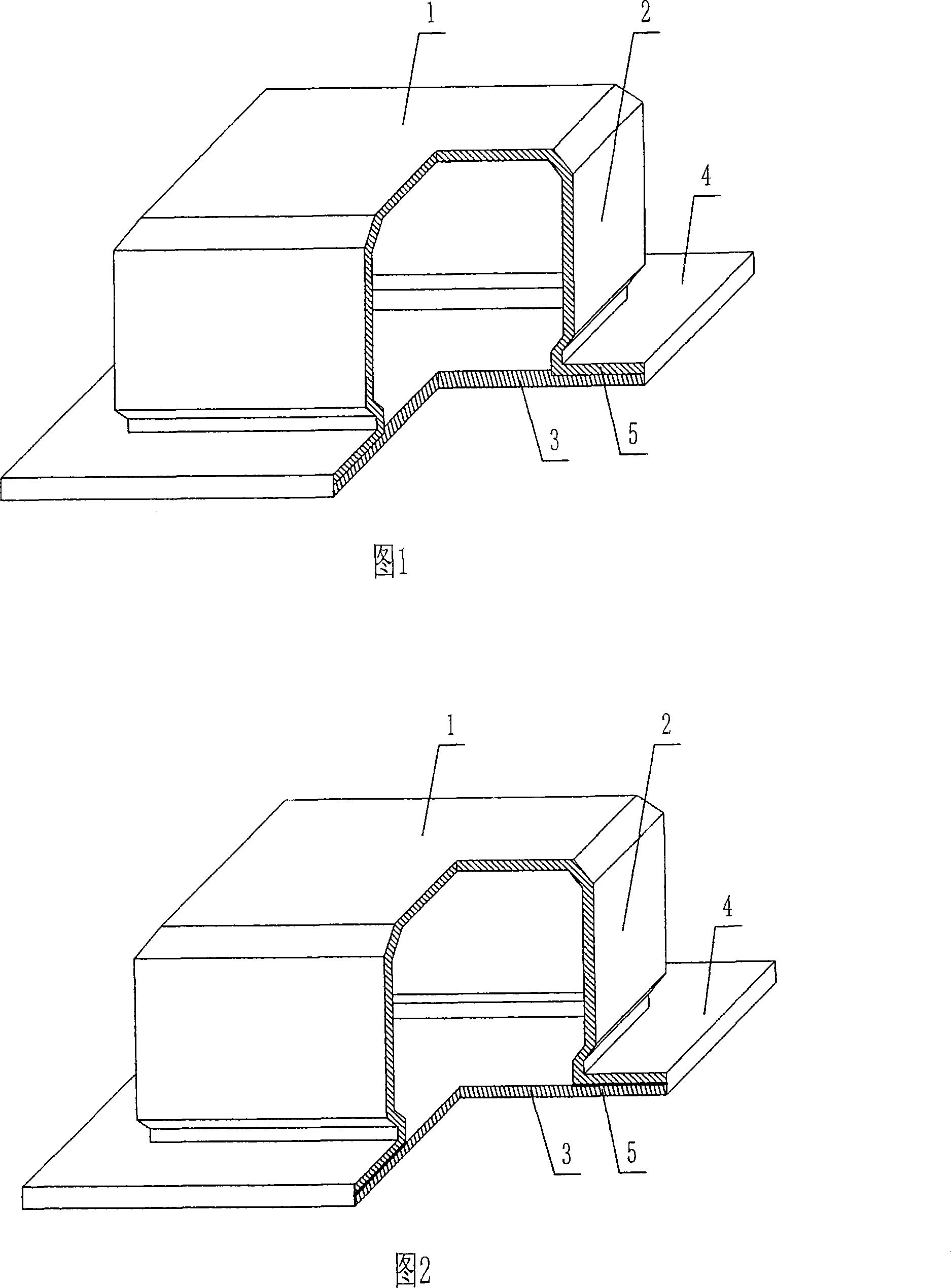

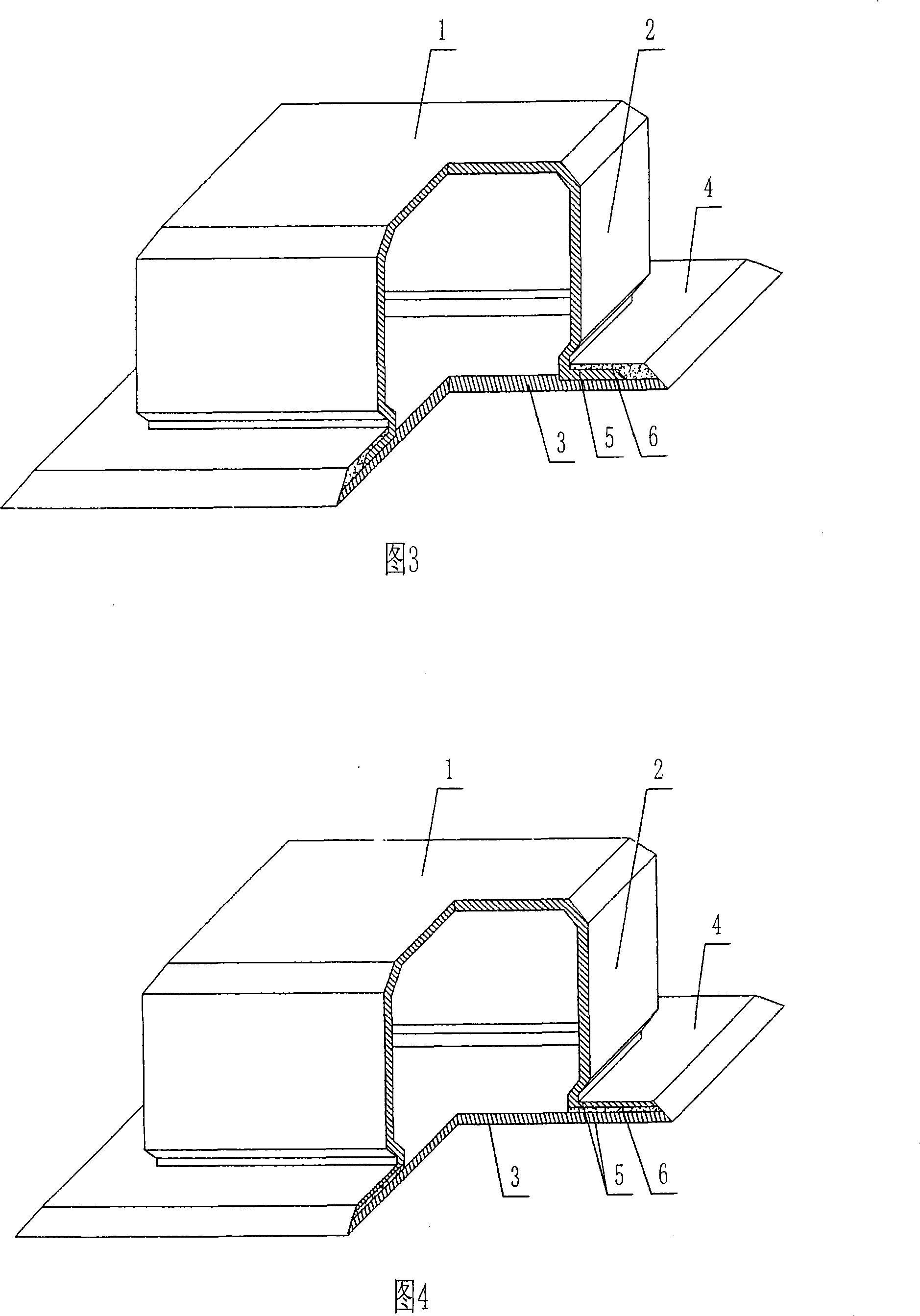

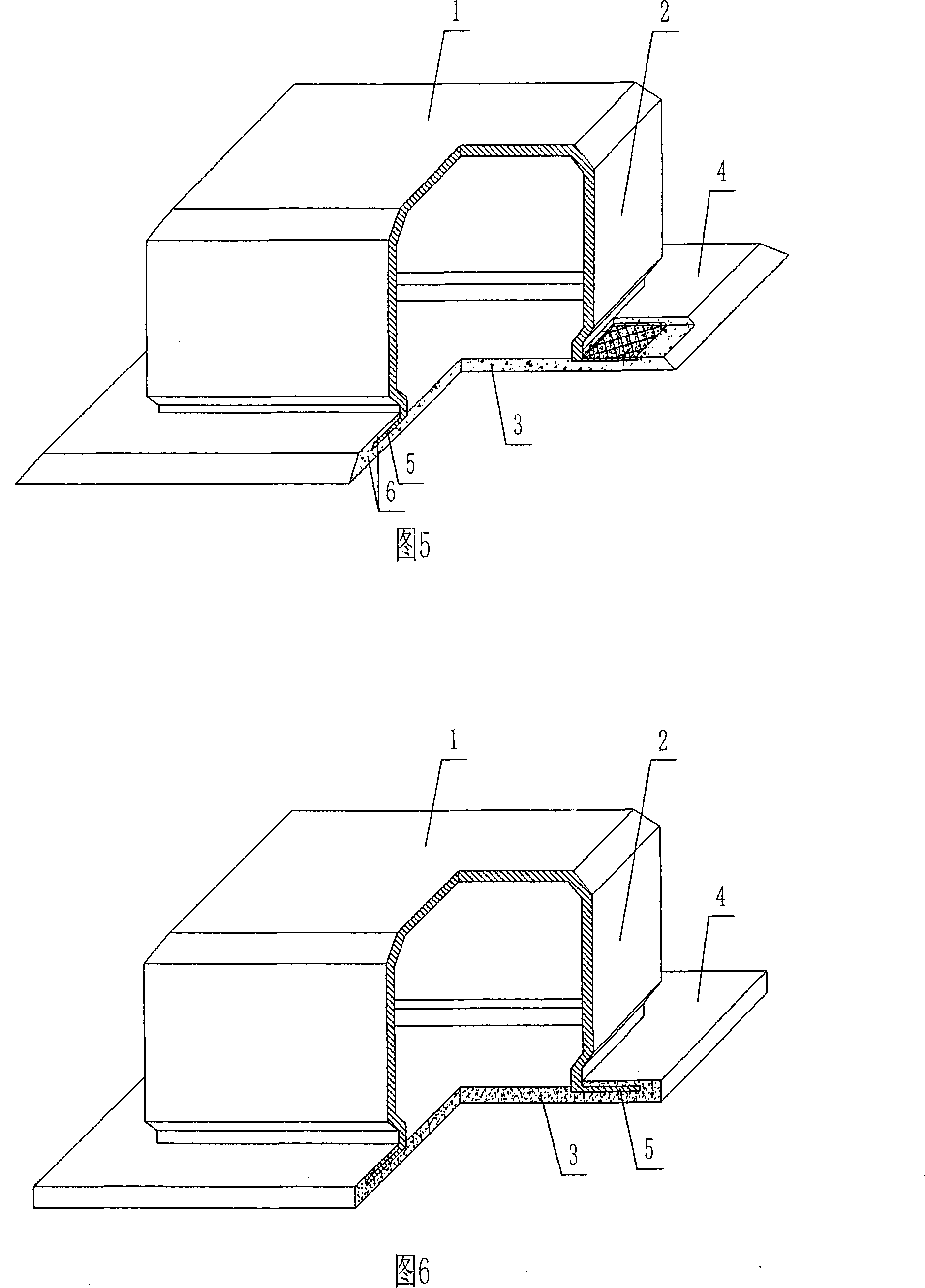

[0062] As shown in the accompanying drawings, the present invention includes an upper plate 1, surrounding side walls 2, lower bottom plate 3, and raised edges 4, the upper plate 1, surrounding side walls 2, and lower bottom plate 3 form a closed cavity, and the prefabricated surrounding side walls 2 It is characterized in that at least one side flange 4 is a laminated layer flange, and the laminated layer flange includes at least one prefabricated layer 5. In each accompanying drawing, 1 is an upper plate, 2 is a surrounding side wall, 3 is a lower bottom plate, 4 is an overhang, and 5 is a prefabricated layer. In the following drawings, those with the same number have the same description. As shown in Figure 1, the upper plate 1, the surrounding side walls 2 and the lower base plate 3 form a closed cavity, and the raised edge 4 protrudes from the peri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com