Directly-down backlight module and blooming piece fixed structure thereof

A technology of optical diaphragm and backlight module, which is applied in optics, nonlinear optics, instruments, etc., can solve problems such as warping and deformation, residual stress of optical diaphragm, etc., and achieve the goal of preventing warping and deformation, improving display quality and optical taste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

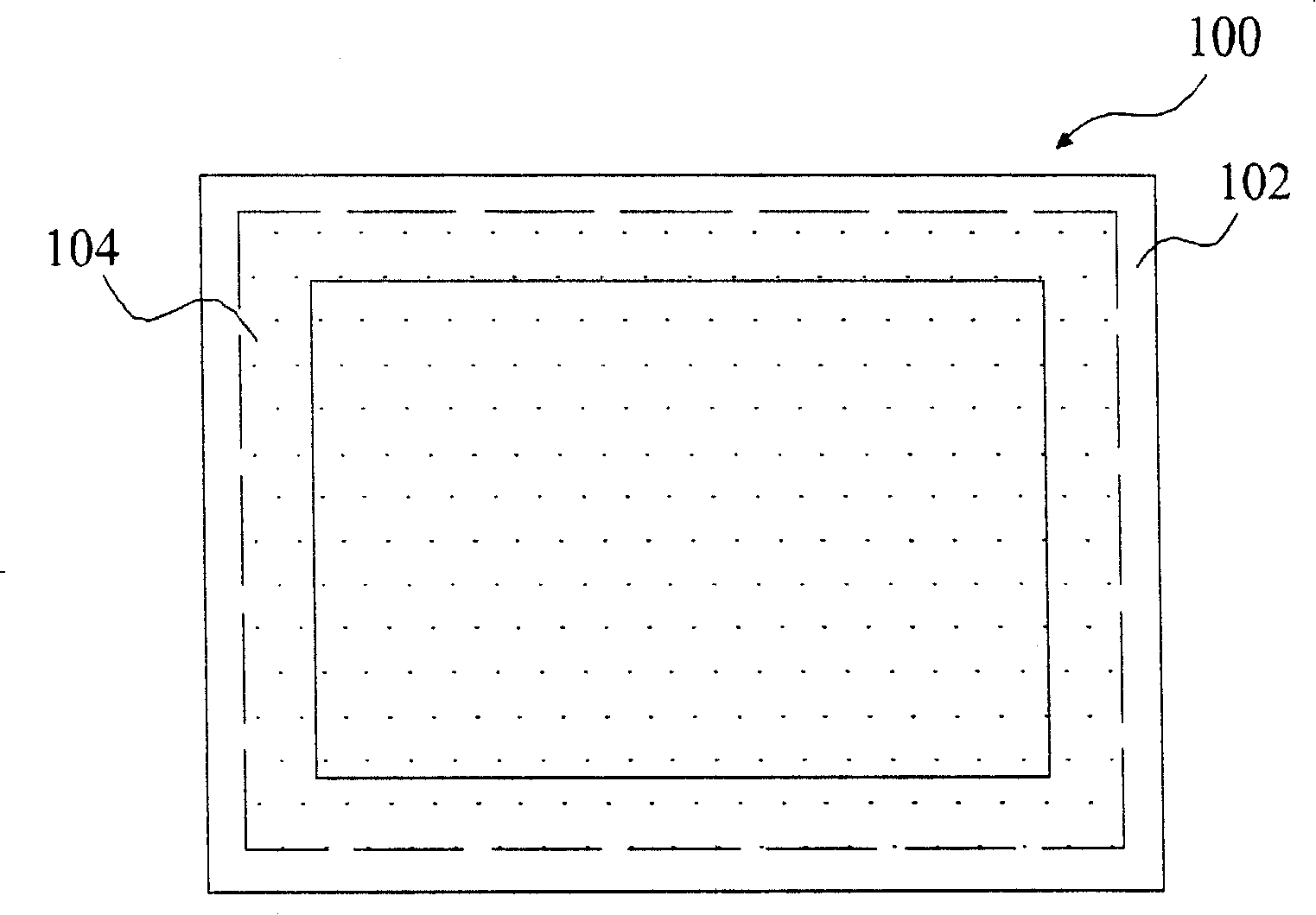

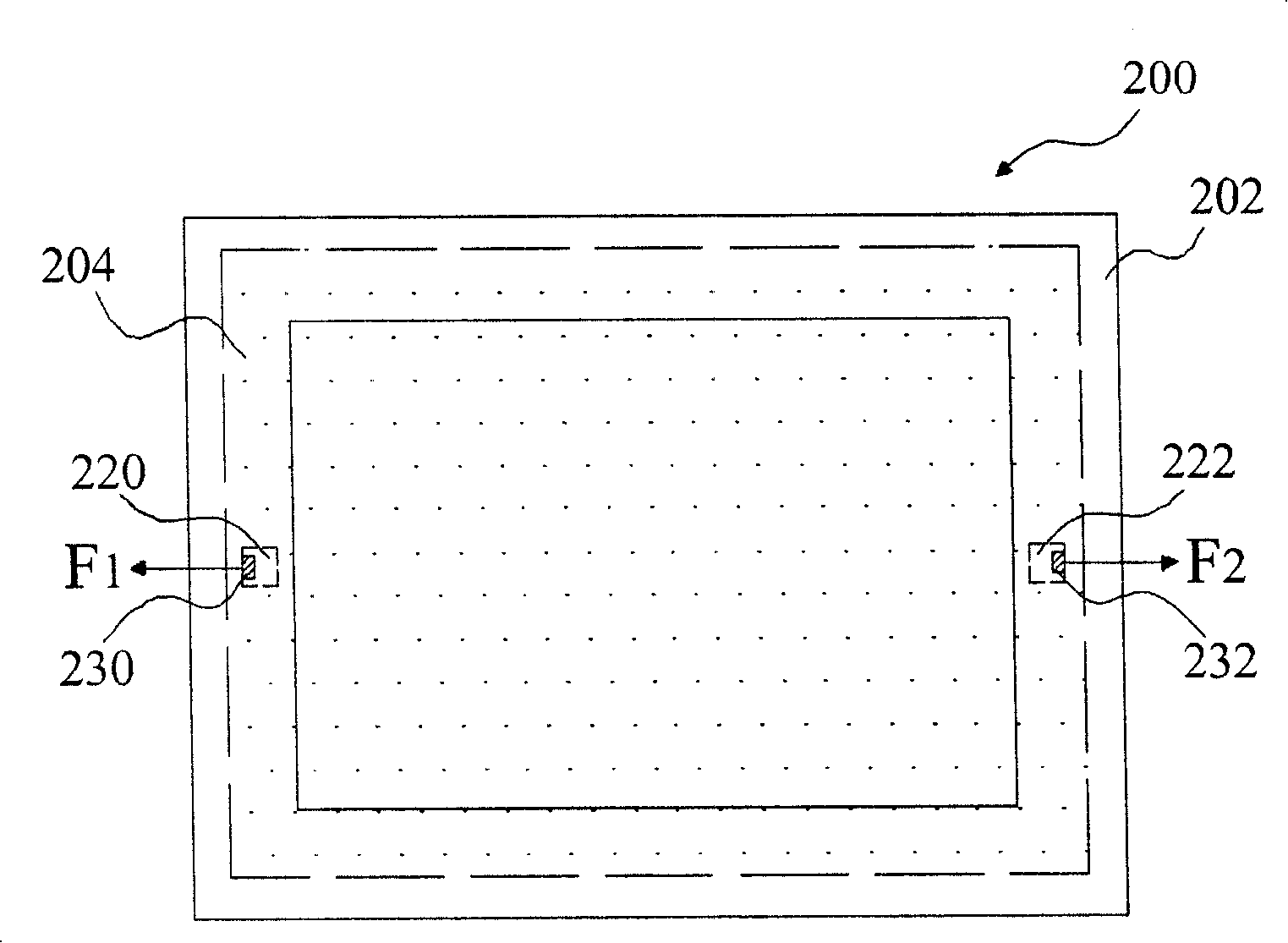

[0025] Figure 2A It is a schematic top view of a direct-type backlight module 200 according to an embodiment of the present invention. The optical film group 204 of the direct-type backlight module 200 is placed under the outer frame 202. The optical film group 204 includes at least one optical film. The frame 202 surrounds and covers the edge of the optical film set 204 , and the part of the optical film set 204 not covered by the outer frame 202 is the display area of the display. The left and right edges of the optical film group 200 located in the non-display area respectively have through holes 220, 222, and two elastic bodies 230, 232 are respectively placed in the through holes 220, 222 and against the edges of the through holes to provide two outward tensions. f 1 , F 2 Given the optical film group 204, the outward tension F 1 with F 2 The optical film group 204 will be maintained flat, and will not be warped due to changes in the temperature and humidity of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com