Artificial hair and wig using the same

A technology for artificial hair and wigs, applied in wigs, applications, conjugated synthetic polymer man-made filaments, etc., can solve the problem of nylon 6T not being practical.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0111] Next, examples of the present invention will be described in detail.

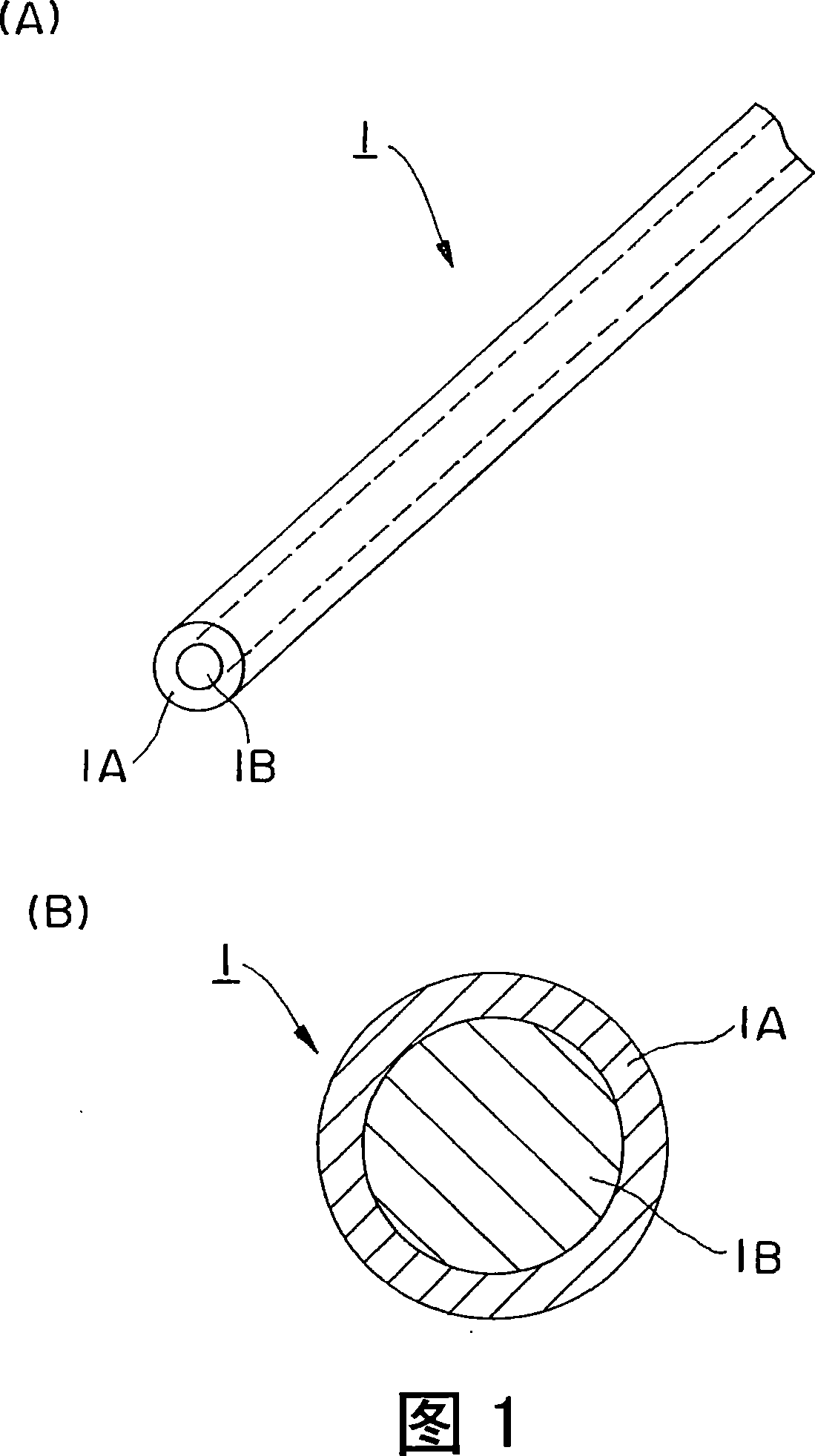

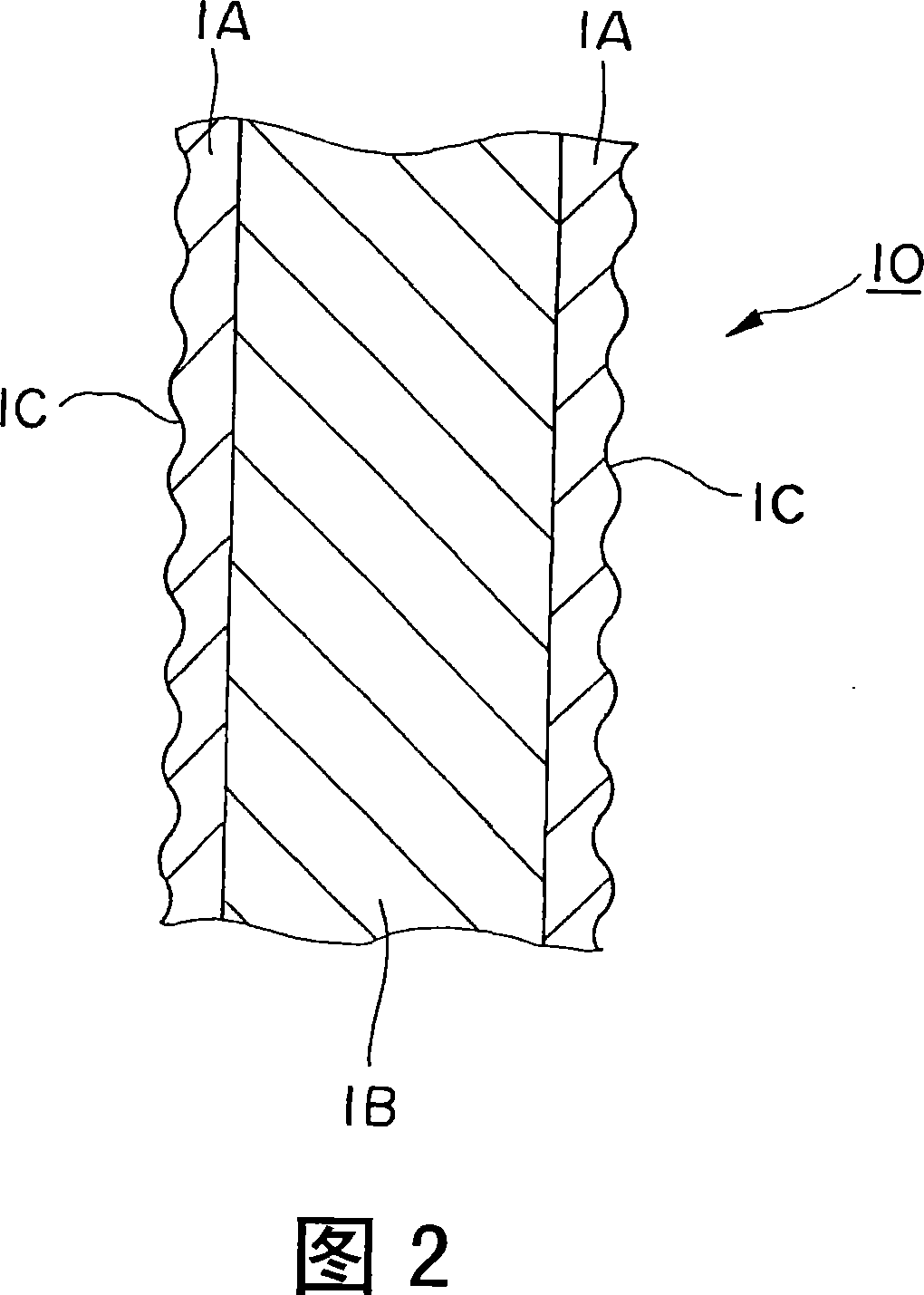

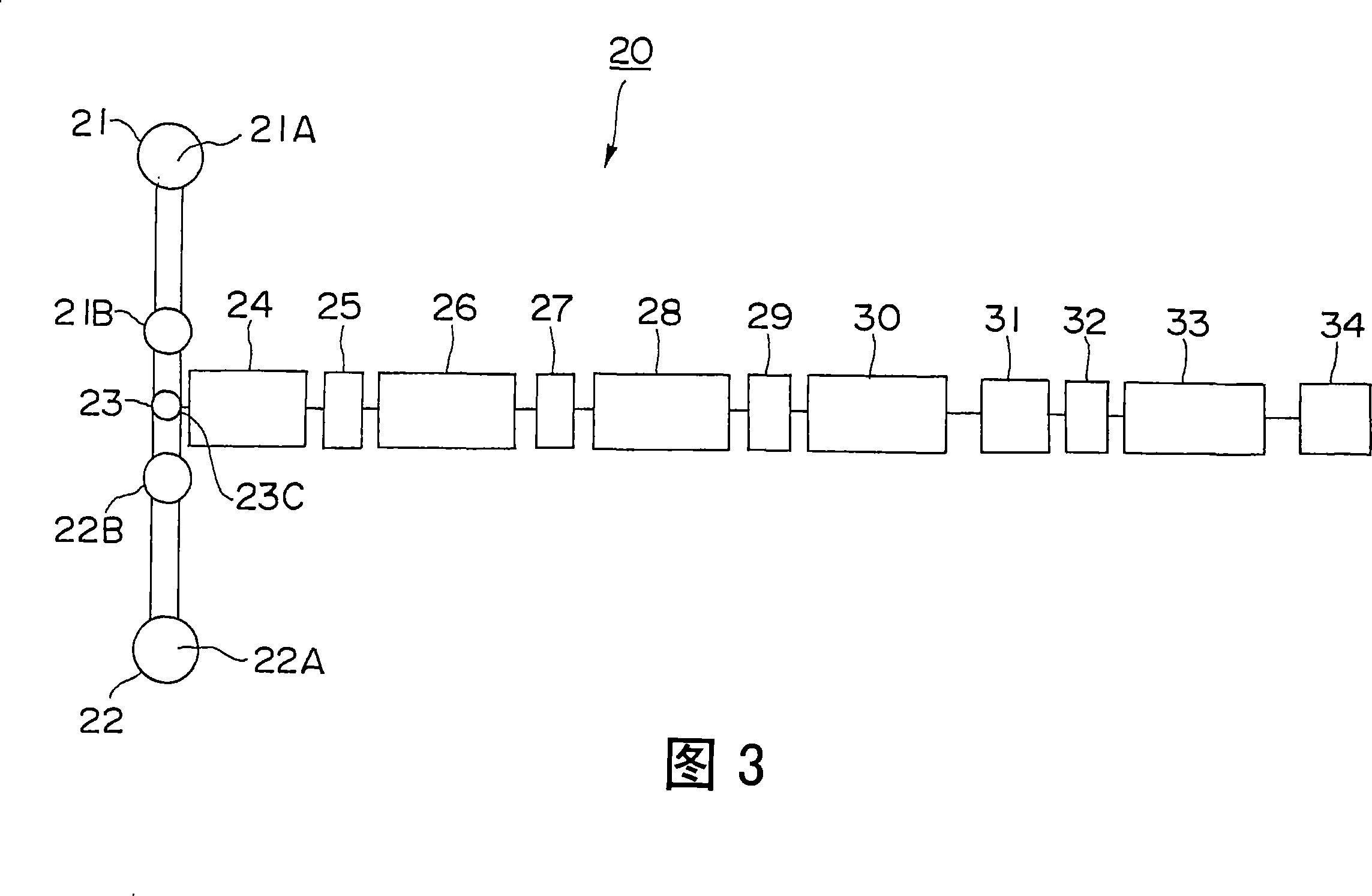

[0112] The artificial hair 10 of Example 1 was manufactured using the spinning machine 20 shown in FIG. 3 . Nylon 6T (manufactured by TOYOBO Corporation) was used as the polyamide resin of the core portion 1B, and nylon 6 (manufactured by TOYOBO Corporation) was used as the polyamide resin of the sheath portion 1A. The hot water bath 24 uses hot water of 80°C. The sheath / core capacity ratio was set to 1 / 7, and the outlet temperature was set to 310° C. to produce artificial hair 10 . The sheath / core weight ratio of the artificial hair 10 of this Example 1 was 12 / 88.

[0113] As a coloring agent, the polyamide resin and pigment used in the sheath 1A or core 1B are mixed in a predetermined ratio, heated and melted, kneaded and then cooled to form a sheet-like resin flake. The resin flake used as this colorant is called a masterbatch. As master batches used in the examples, resin flakes containing 3%...

Embodiment 2

[0121] The artificial hair 10 having the sheath / core structure was produced under the same conditions as in Example 1 except that the gear pumps 21B, 22B were adjusted so that the sheath / core capacity ratio was 1 / 5. The sheath / core weight ratio of the artificial hair 10 of this Example 2 was 16.1 / 83.9.

Embodiment 3

[0123] The artificial hair 10 having the sheath / core structure was produced under the same conditions as in Example 1 except that the gear pumps 21B, 22B were adjusted so that the sheath / core capacity ratio was 1 / 3. The artificial hair 10 of Example 3 had a sheath / core weight ratio of 24.2 / 75.8 and a diameter of 80 μm.

[0124] FIG. 7 is a graph showing the elongation ratio dependence of the bending rigidity value of the artificial hair 10 of Example 3. FIG. In the figure, the horizontal axis represents the elongation ratio, and the vertical axis represents the bending rigidity value (10 -5 gfcm 2 / root). The measurement conditions were a temperature of 22° C. and a humidity of 40%. It can be seen from Figure 7 that the bending rigidity values of 3 times and 5.5 times of elongation are respectively 430×10 -5 gfcm 2 / root, 720×10 -5 gfcm 2 / root, the bending rigidity increases linearly as the elongation ratio increases.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com