Micro-wave oven

A technology for microwave ovens and oven doors, which is applied in the directions of ovens/stove doors, household ovens/stoves, oven/stove brackets/shelves, etc., can solve the problems of steaming, occupying a lot of space, and being bulky, and achieves a simple and reasonable structure. The effect of improving the utilization rate and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

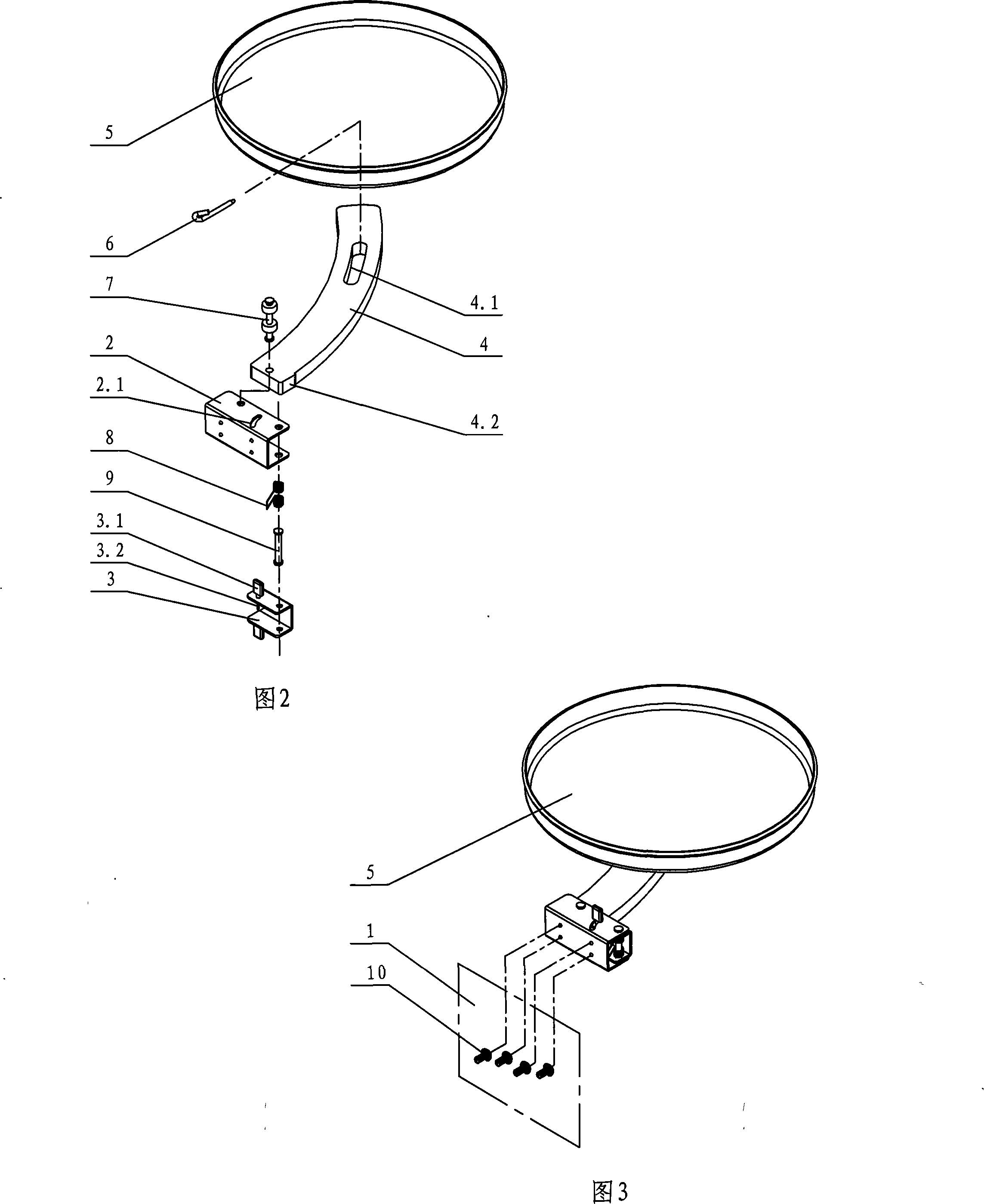

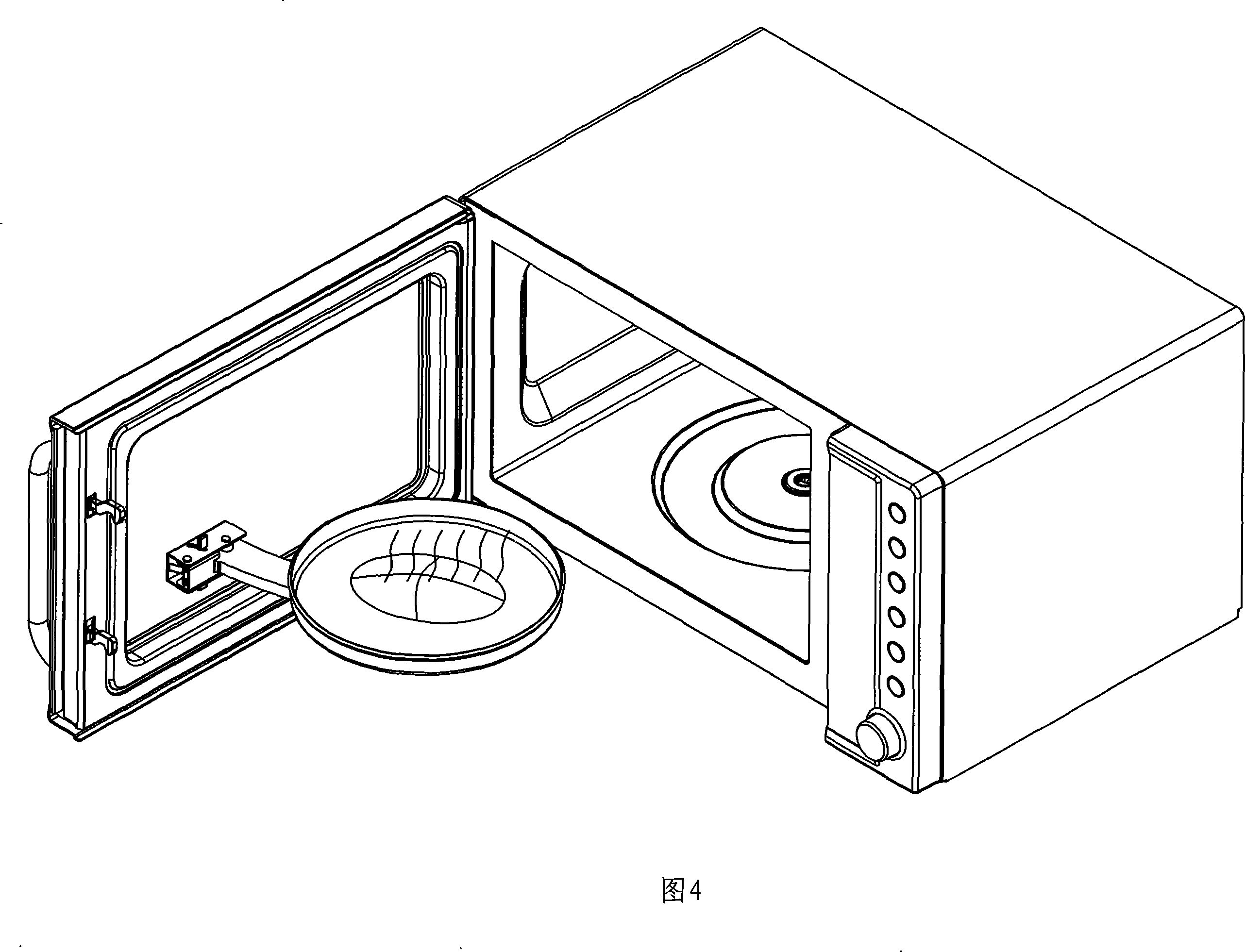

[0015] In the figure: 1 is the furnace door, 2 is the support, 2.1 is the guide groove, 3 is the limit block, 3.1 is the wrench, 3.2 is the limit opening slot, 4 is the rotating arm bracket, 4.1 is the chute, 4.2 is the limit Boss, 5 is a food tray, 5.1 is a positioning column, 6 is a latch, 7 is a rotating shaft, 8 is a torsion spring, 9 is a fixed shaft, and 10 is a screw.

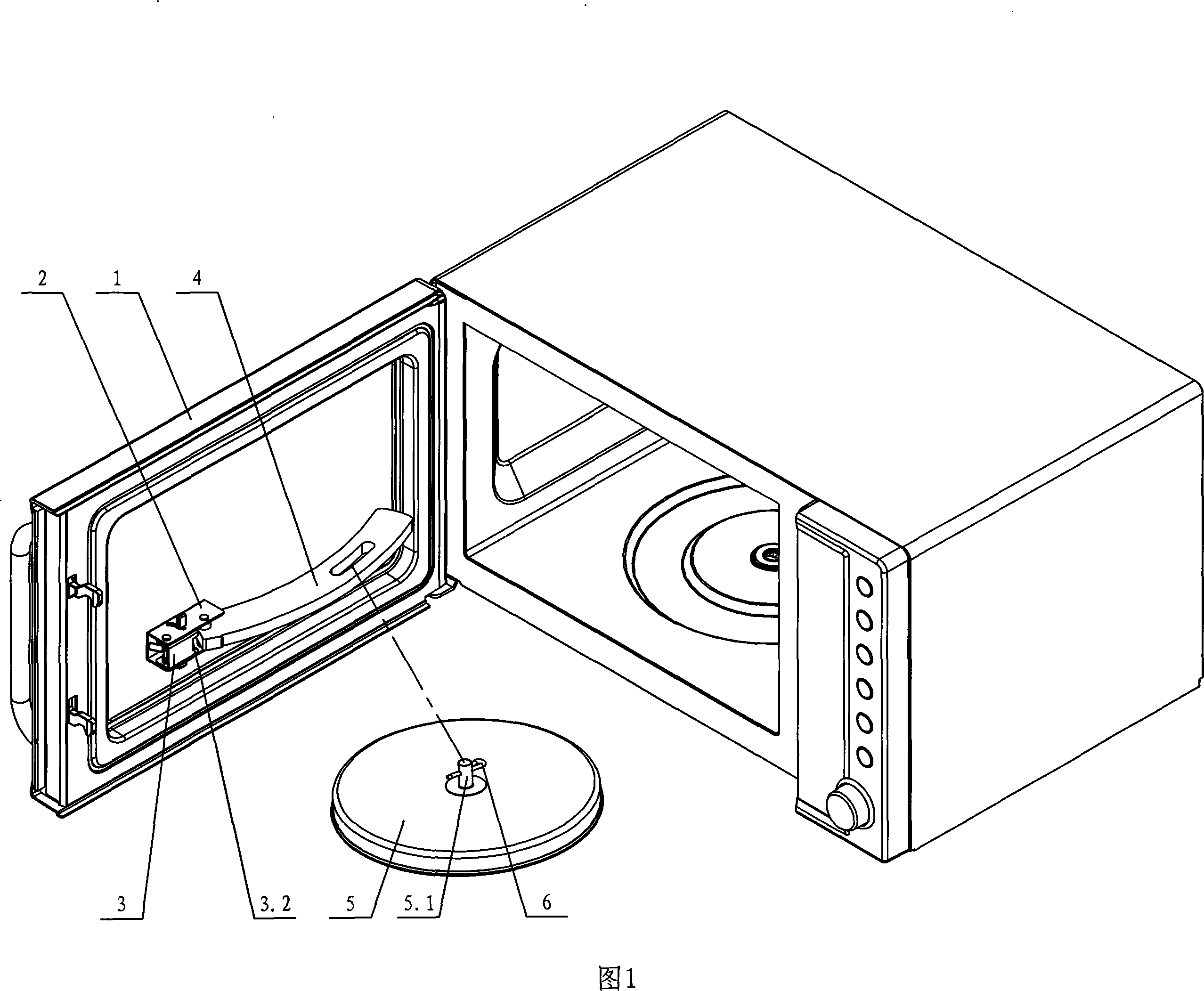

[0016] Referring to Fig. 1-Fig. 5, the microwave oven includes a furnace door 1, which is provided with a door-opening food take-out mechanism, which includes a food tray 5 connected to the inner side of the furnace door through a rotating arm bracket 4, and the food tray is circular. , oval, square or rectangular.

[0017] There is a support 2 on the furnace door 1, and a limit block 3 is arranged on the support. One end of the limit block is hinged on the support through a fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com