Device and method for application of an even thin fluid layer to substrates

A thin liquid layer and equipment technology, applied in liquid injection devices, sustainable manufacturing/processing, photovoltaic power generation, etc., can solve condensation dripping, hinder uniform wetting or uniform coating, and cannot ensure uniform distribution of fog, etc. problem, to achieve the effect of improving uniformity, uniformity and effective transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

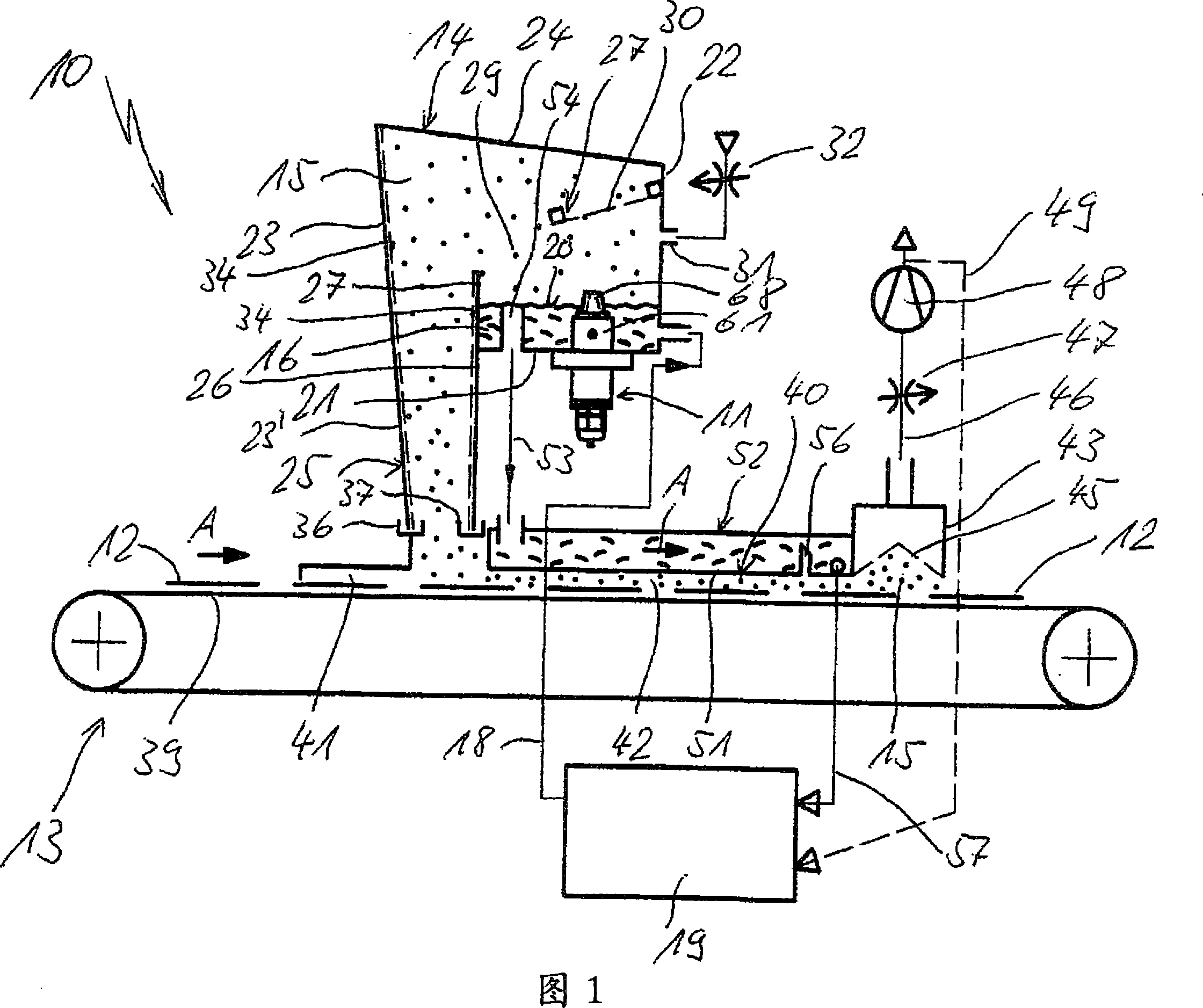

[0029] The function of the device 10 as described in FIG. 1 is to apply a uniform thin phosphoric acid layer to a silicon substrate or cell 12 for photovoltaic applications. In this article, the silicon substrate 12 is passed in and out along the direction of arrow A on the conveying device 13, and during the conveying movement, the silicon substrate 12 is conveyed through the high-frequency ultrasonic device 11 in the processing chamber 14. The phosphoric acid mist 15 makes the phosphoric acid layer of the silicon substrate 12 uniform.

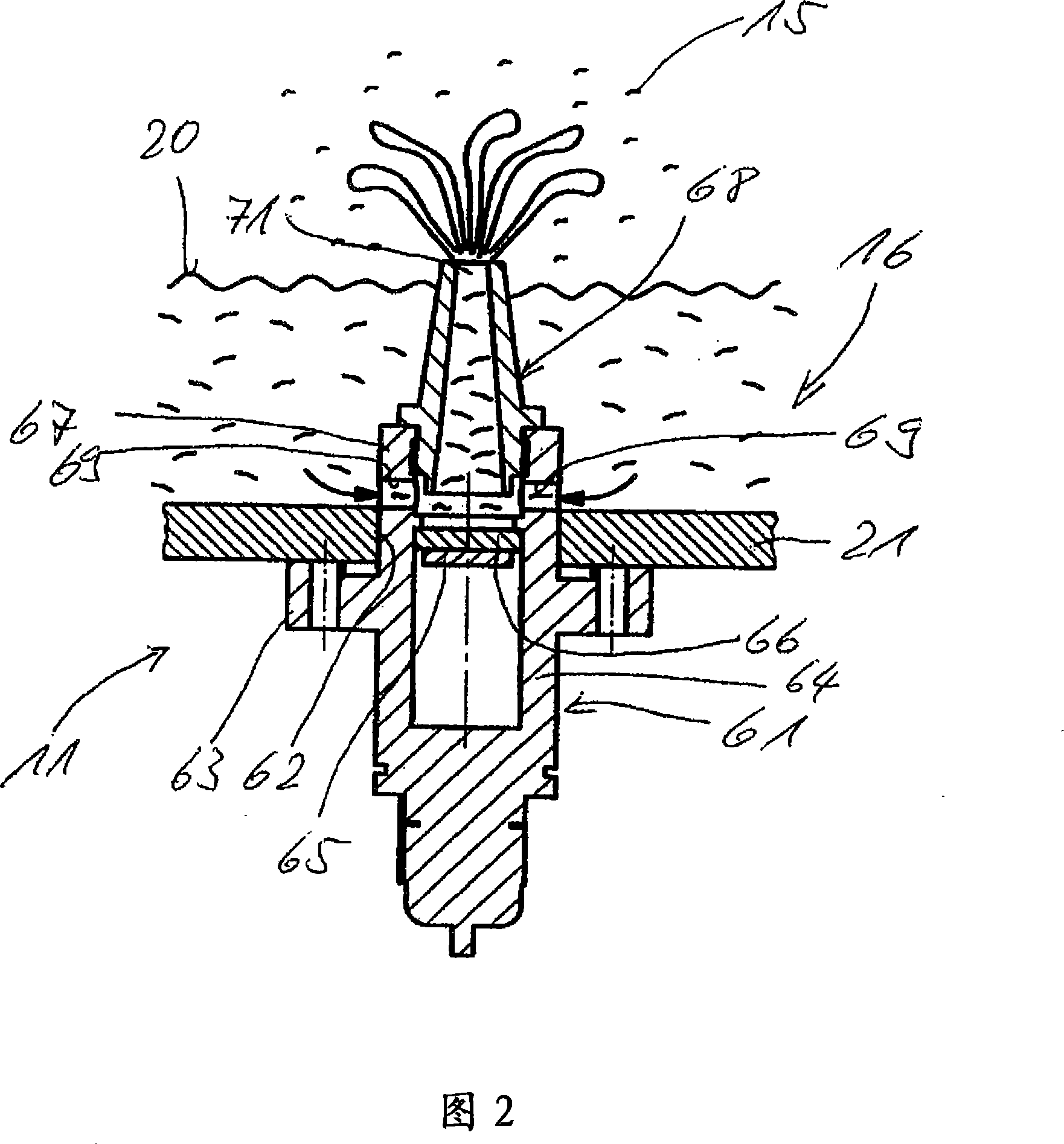

[0030] According to FIG. 1, the tray 16 containing phosphoric acid is arranged on the bottom of the processing chamber 14 extending in a prescribed length perpendicular to the plane of the drawing. The phosphoric acid pan 16 is connected to the phosphoric acid tank 19 through a pipeline 18. Advantageously, the phosphoric acid from the tank 19 in the pan 16 can be adjusted as required. A high-frequency ultrasonic device 11 is attached to the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com