Bi-directional two stage composite filter structure

A filter and secondary technology, applied in the fields of filtration and separation, filtration circuits, chemical instruments and methods, etc., can solve the problems of complex components, insufficient automation of the double lubricating oil filter, and membrane blockage, etc., and achieve significant economic benefits and Social benefits, significant filtering effect, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

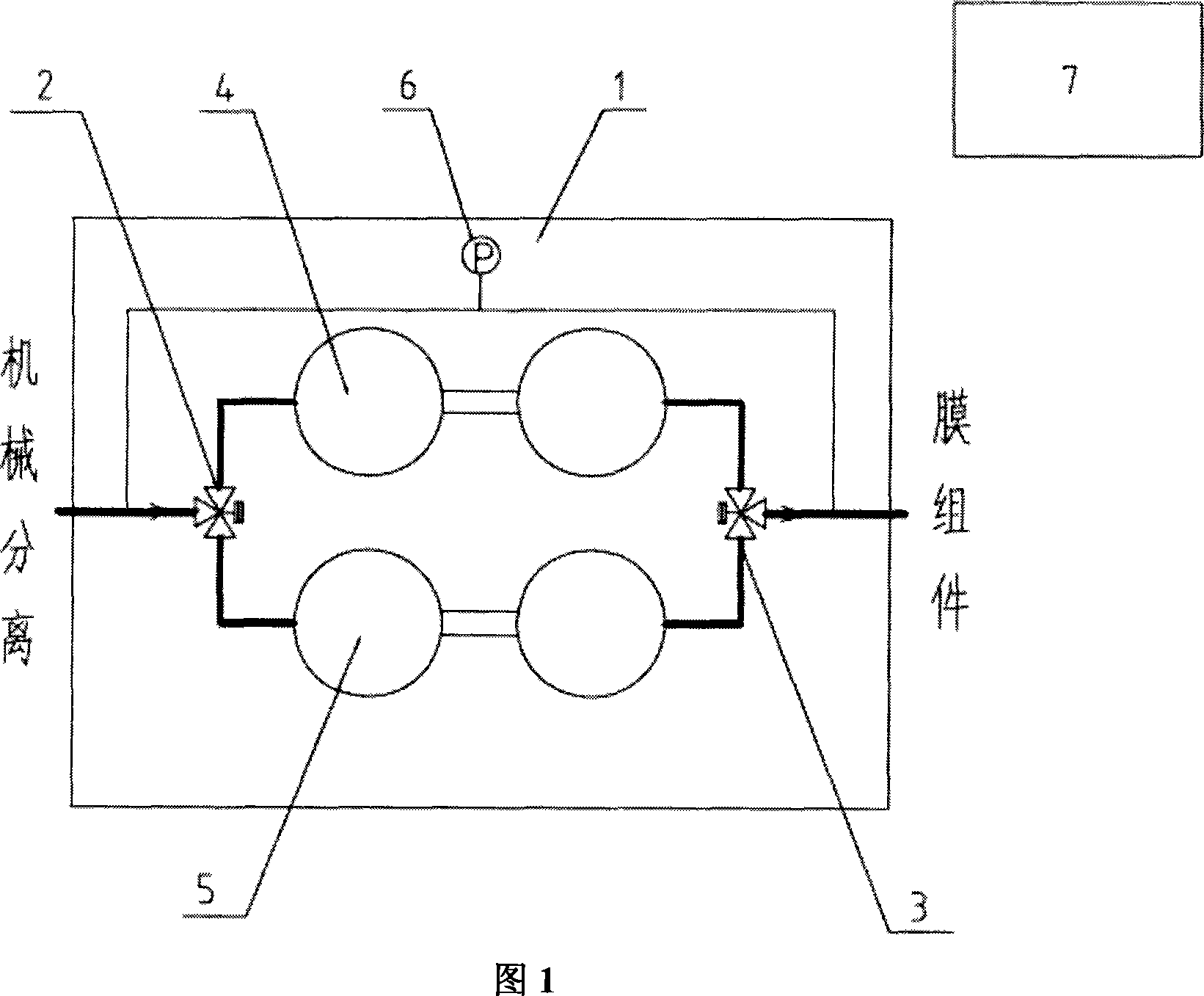

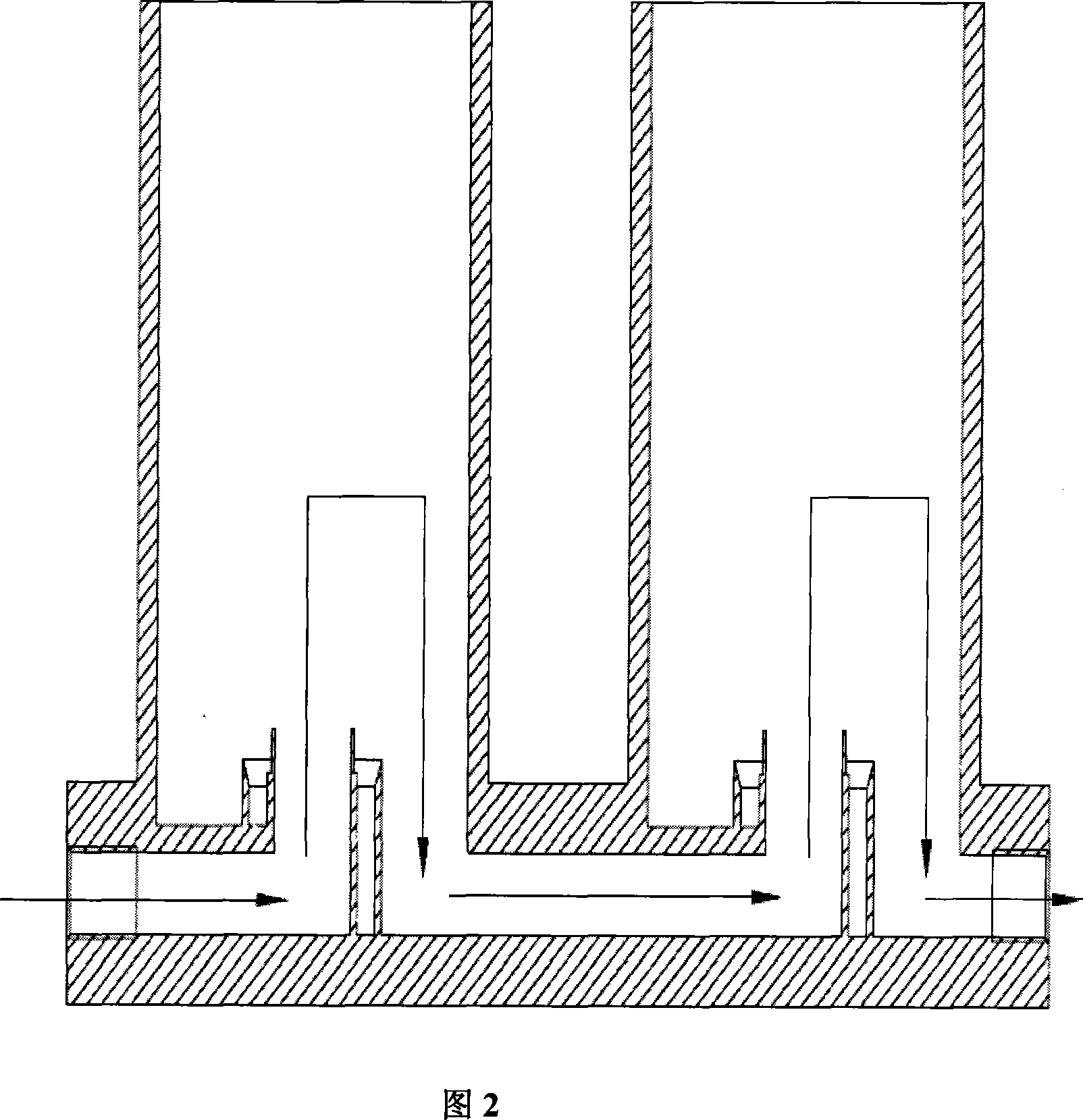

[0010] As shown in Figure 1 and Figure 2, the present invention includes a base plate 1, A two-position three-way solenoid valve 2, B two-position three-way solenoid valve 3, A secondary combination filter 4, B secondary combination filter 5, and a differential pressure sensor 6. Control unit 7. Among them, A secondary combination filter 4 and B secondary combination filter 5 adopt two self-designed oil filters cast in series to form an integrated structure. The filter 4 and the B secondary combination filter 5 are fixed on the bottom plate 1 . Port a of A two-position three-way solenoid valve 2 is connected to the outlet of mechanical separation, port b and port c are respectively connected to the inlets of A secondary combination filter 4 and B secondary combination filter 5; B two-position three-way solenoid valve 3 port a of the mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com