Stop position control method and apparatus of rotary stencil printing press

A technology of stop position and printing method, which is applied to rotary printing machines, general parts of printing machinery, printing machines, etc., can solve the problems of shortened life of motors and motor bearings, deterioration of grease, and increased power consumption, etc., to achieve Conducive to diversification, increase the degree of freedom, improve the effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

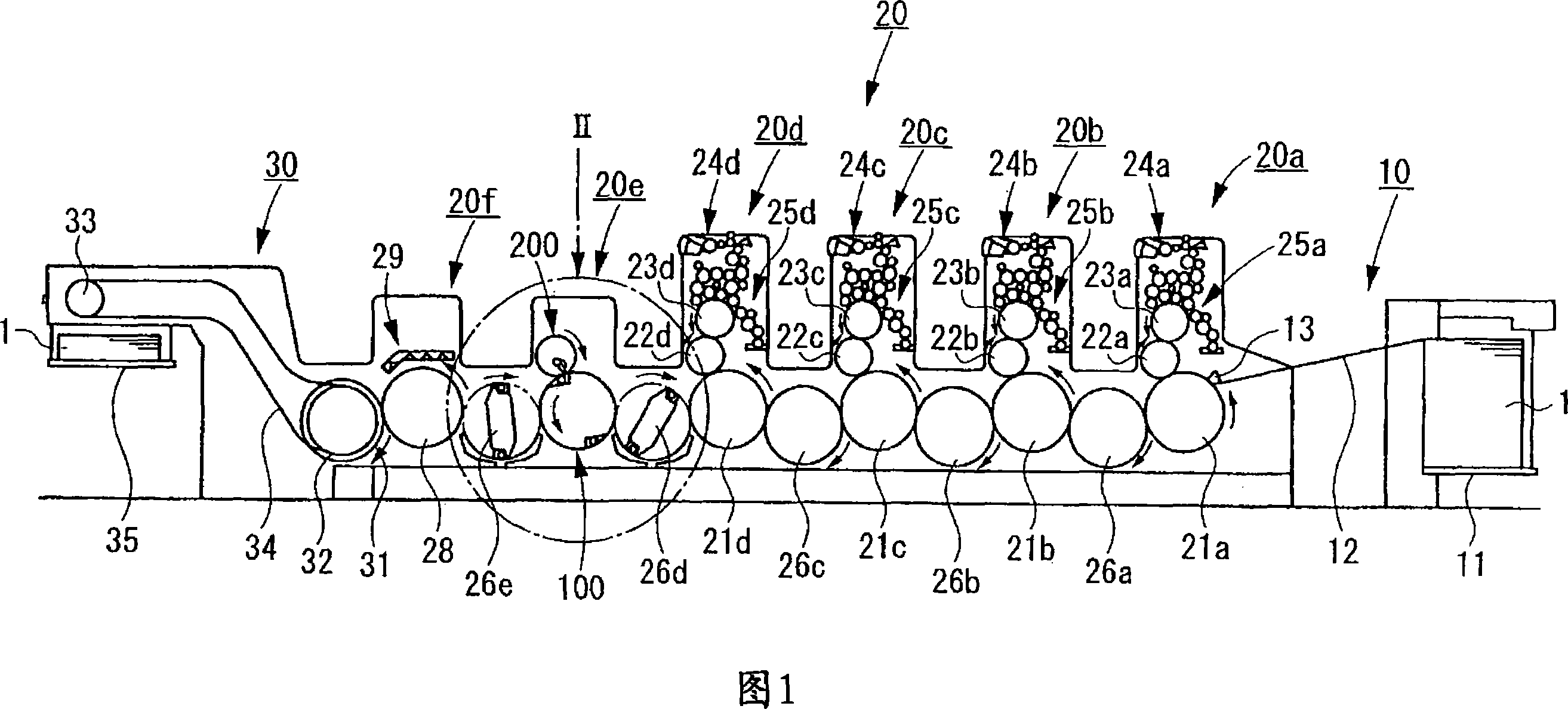

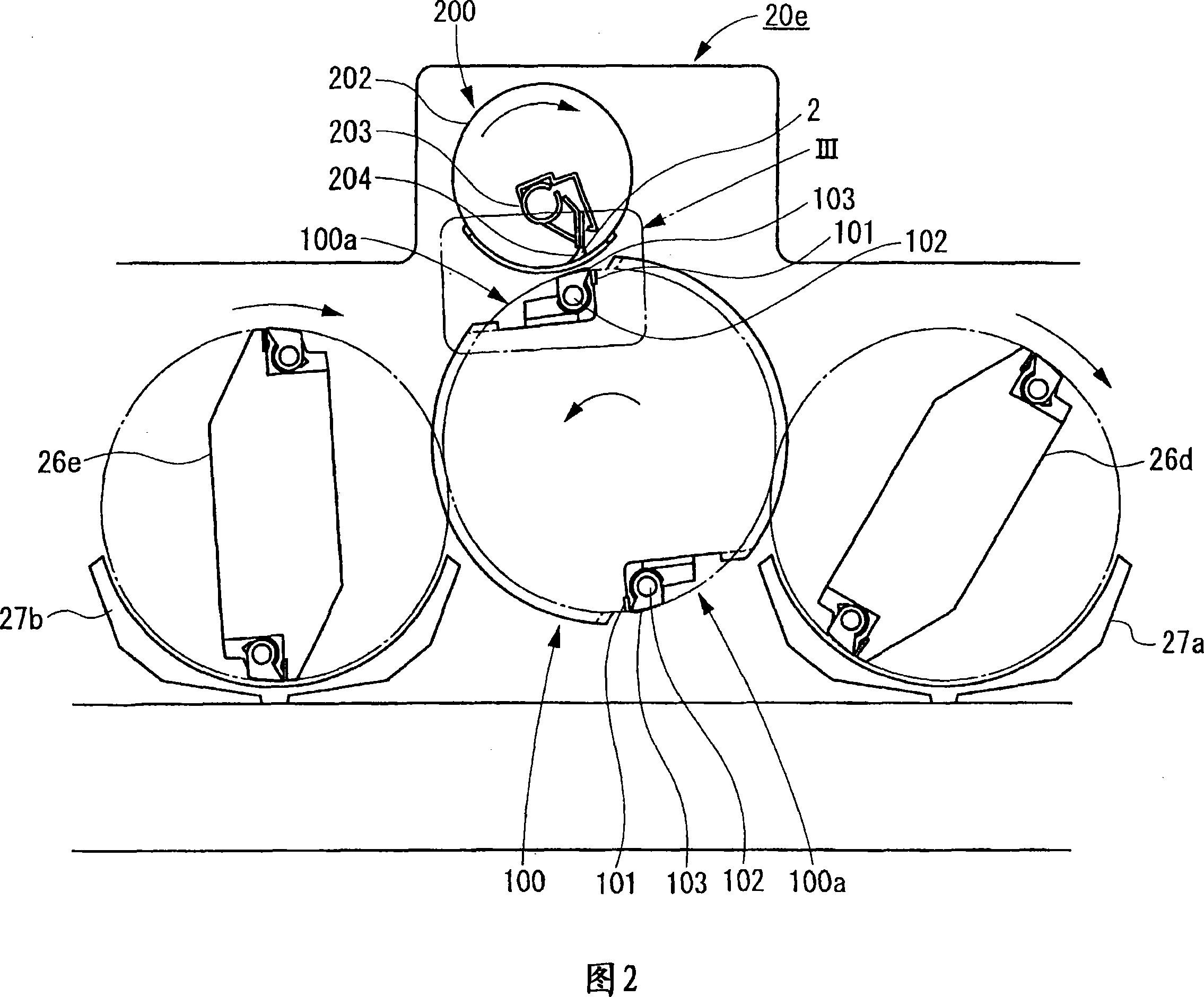

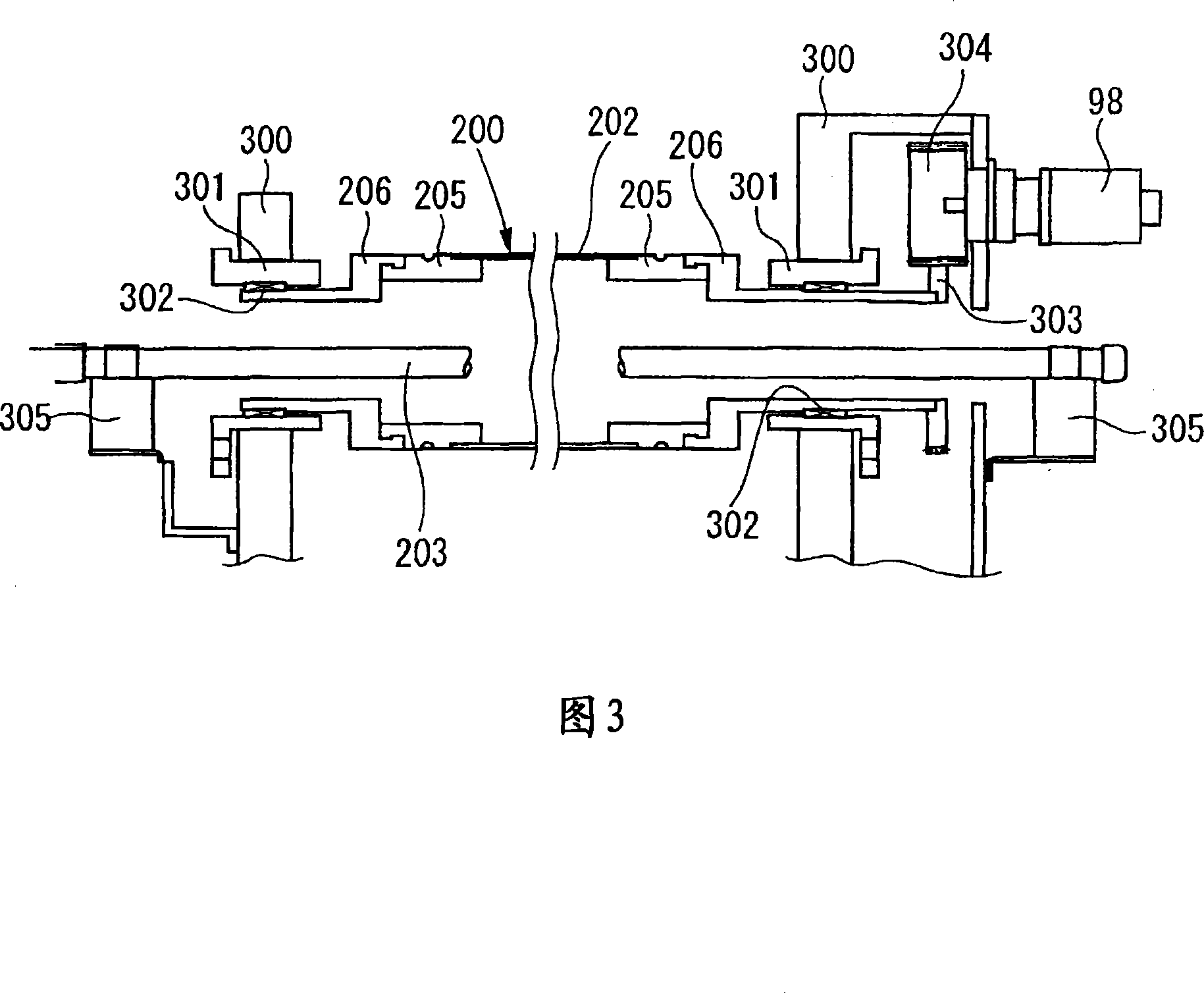

[0072] Fig. 1 is a schematic diagram showing the overall structure of an offset sheet-fed printing machine according to a first embodiment of the present invention; Fig. 2 is an enlarged view of part II in Fig. 1; Fig. 3 is a cross-sectional view of a rotary screen device; A cross-sectional view of the plate vise device of the plate cylinder, Figure 5 is an explanatory diagram of its function, Figure 6 is a block diagram of a drive control device for an offset sheet-fed printing machine, and Figure 7 is a block diagram of a drive control device for a rotary screen cylinder, Fig. 8(a) to 8(d) are the operation flowcharts of the drive control device of the offset sheet-fed printing press, and Fig. 9(a) and Fig. 9(b) are the actions of the drive control device of the offset sheet-fed printing press Flowchart, Fig. 10(a) ~ Fig. 10(c) are the operation flowchart of the drive control device of the offset sheet-fed printing machine, Fig. 11 is the operation flow chart of the drive con...

no. 2 example

[0169] Fig. 15 is a block diagram showing a drive control device for an offset sheet-fed printing machine according to a second embodiment of the present invention, Fig. 16 is a block diagram of a drive control device for a rotary screen cylinder, and Fig. 17(a) to Fig. 17(d) are Figure 18(a)-Figure 18(b) is an action flow chart of the drive control device for the offset sheet-fed printing press, Figure 19(a)-Figure 19 (c) is an action flow chart of the drive control device of the offset sheet-fed printing press, and Fig. 20 is an action flow chart of the drive control device of the offset sheet-fed printing press, and Fig. 21 (a) and Fig. 21 (b) are rotation The action flowchart of the drive control device of the screen cylinder, Figure 22 (a) and Figure 22 (b) are the action flow charts of the drive control device of the rotary screen cylinder, Figure 23 is the action of the drive control device of the rotary screen cylinder flow chart.

[0170] This embodiment is such an exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com