Baking-free enamel paint glaze sanitary equipment and processing method thereof

A sanitary ware and enamel technology, applied in the field of sanitary ware, can solve the problems of uneven glaze color, high energy consumption, high production cost, etc., and achieve the effect of improving the appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

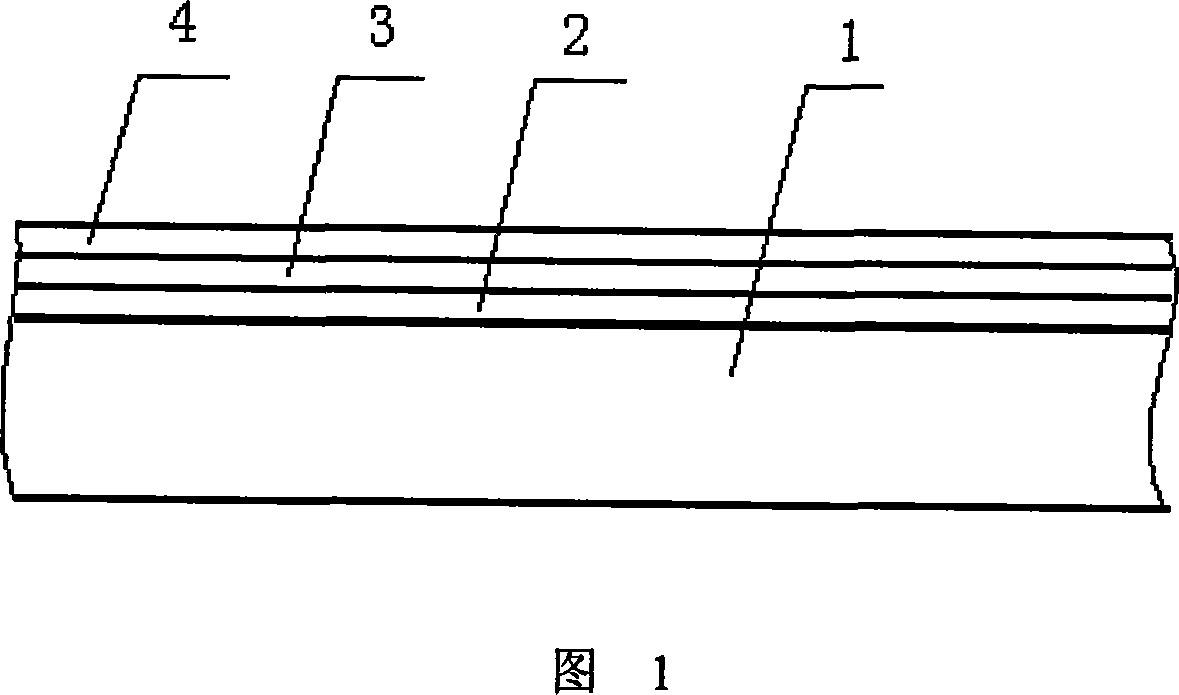

[0019] A new type of fire-free enamel glazed sanitary ware comprises a body 1 of the sanitary ware, the surface of which is coated with enamel glaze, and the enamel glaze consists of a transition layer 2, a decorative layer 3 and a bright layer 4 from bottom to top. The transition layer is made of acrylic-polyurethane two-component mixed with curing agent and diluent according to the weight ratio of 100:25:25, and the mixture is 1000m mesh. The decorative layer is made of thermosetting acrylic resin, amino resin, coloring material, auxiliary agent and The organic solvent is prepared by mechanical processing to 1000 mesh, and the material of the bright layer is composed of thermosetting acrylic acid, amino resin, leveling agent and nano oxide according to 2:1:0.3 composition of 1000 mesh.

[0020] A method for processing a novel non-burning enamel glaze sanitary ware, comprising the following steps:

[0021] a. Biscuit firing: according to the conventional sanitary ware body pr...

Embodiment 2

[0028] A new type of fire-free enamel glazed sanitary ware comprises a body 1 of the sanitary ware, the surface of which is coated with enamel glaze, and the enamel glaze consists of a transition layer 2, a decorative layer 3 and a bright layer 4 from bottom to top. The transition layer is made of acrylic-polyurethane two-component mixed with curing agent and diluent according to the weight ratio of 100:30:40, and the mixture is 1000m mesh. The decorative layer is made of thermosetting acrylic resin, amino resin, coloring material, auxiliary agent and The organic solvent is prepared by mechanical processing to 1000 mesh, and the material of the bright layer is composed of thermosetting acrylic acid, amino resin, leveling agent and nano oxide according to 2:1:0.5 composition of 1000 mesh.

[0029] 3. A method for processing a new type of non-fired enamel glazed sanitary ware, comprising the following steps:

[0030] a. Biscuit firing: according to the conventional sanitary ware...

Embodiment 3

[0036] A new type of fire-free enamel glazed sanitary ware comprises a body 1 of the sanitary ware, the surface of which is coated with enamel glaze, and the enamel glaze consists of a transition layer 2, a decorative layer 3 and a bright layer 4 from bottom to top. The transition layer is made of acrylic-polyurethane two-component mixed with curing agent and diluent according to the weight ratio of 100:28:28, and the mixture is 1000m mesh. The decorative layer is made of thermosetting acrylic resin, amino resin, coloring material, auxiliary agent and The organic solvent is prepared by mechanical processing to 1000 mesh, and the material of the bright layer is composed of thermosetting acrylic acid, amino resin, leveling agent and nano oxide according to 2:1:0.4 composition of 1000 mesh.

[0037] 3. A method for processing a new type of non-fired enamel glazed sanitary ware, comprising the following steps:

[0038] a. Biscuit firing: according to the conventional sanitary ware...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap