Antistatic resin composition, antistatic/pressure-sensitive-adhesive resin composition, pressure-sensitive adhesive film, and method for producing the same

A technology of antistatic resin and resin composition, applied in the direction of film/flaky adhesives, adhesives, etc., can solve the problems of complex process, unfavorable economy, insufficient antistatic effect, etc., to achieve control of adhesive strength, antistatic The effect of excellent properties, excellent transparency and viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0279] In preparation of the composition, the above-mentioned ingredient (E4) may be mixed alone, or as a mixture (composition) with the above-mentioned ingredient (A), ingredient (B), ingredient (C) and the like. In the latter case, the miscibility in the composition can be improved.

[0280] A single one of the above-mentioned ingredients (E4), or a combination of two or more kinds may be used.

[0281] When only component (E4) is used as component (E), assuming that the total amount of component (A), component (B) and component (C) is 100% by mass, component (E4) in the antistatic resin composition of the present invention ) content is preferably 0.01 to 30% by mass, more preferably 0.05 to 20% by mass, further preferably 0.1 to 10% by mass, particularly preferably 0.5 to 5% by mass. When the content of component (E4) is excessive, the appearance of molded articles is sometimes poor, and when the content is too low, the antistatic improving effect is sometimes insufficient...

Embodiment approach i

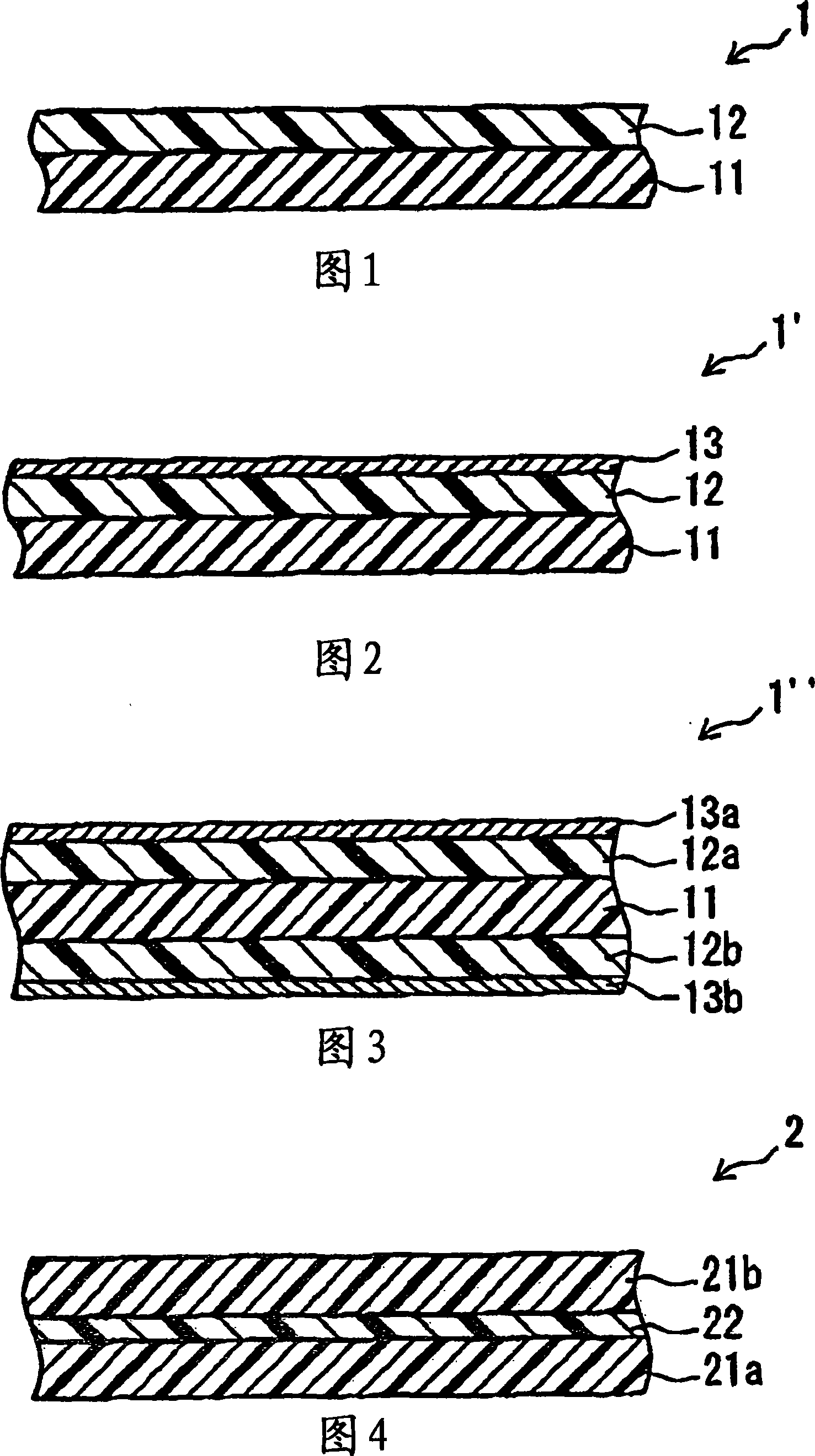

[0424] Embodiment [i] wherein the film comprises a support consisting of ingredient (A) alone (hereinafter referred to as "support (1)") and an antistatic adhesive layer;

Embodiment approach ii

[0425] Embodiment [ii] wherein the film comprises a support composed of the antistatic resin composition of the present invention (hereinafter referred to as "support (2)") and an antistatic adhesive layer; and

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap