Brush holder in electric motor

A technology of electric motors and brush holders, which is applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problems of light weight, miniaturization, increased outer diameter of the yoke or housing, and low production efficiency, etc., to achieve miniaturization The effect of increasing the degree of freedom of design and improving the assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

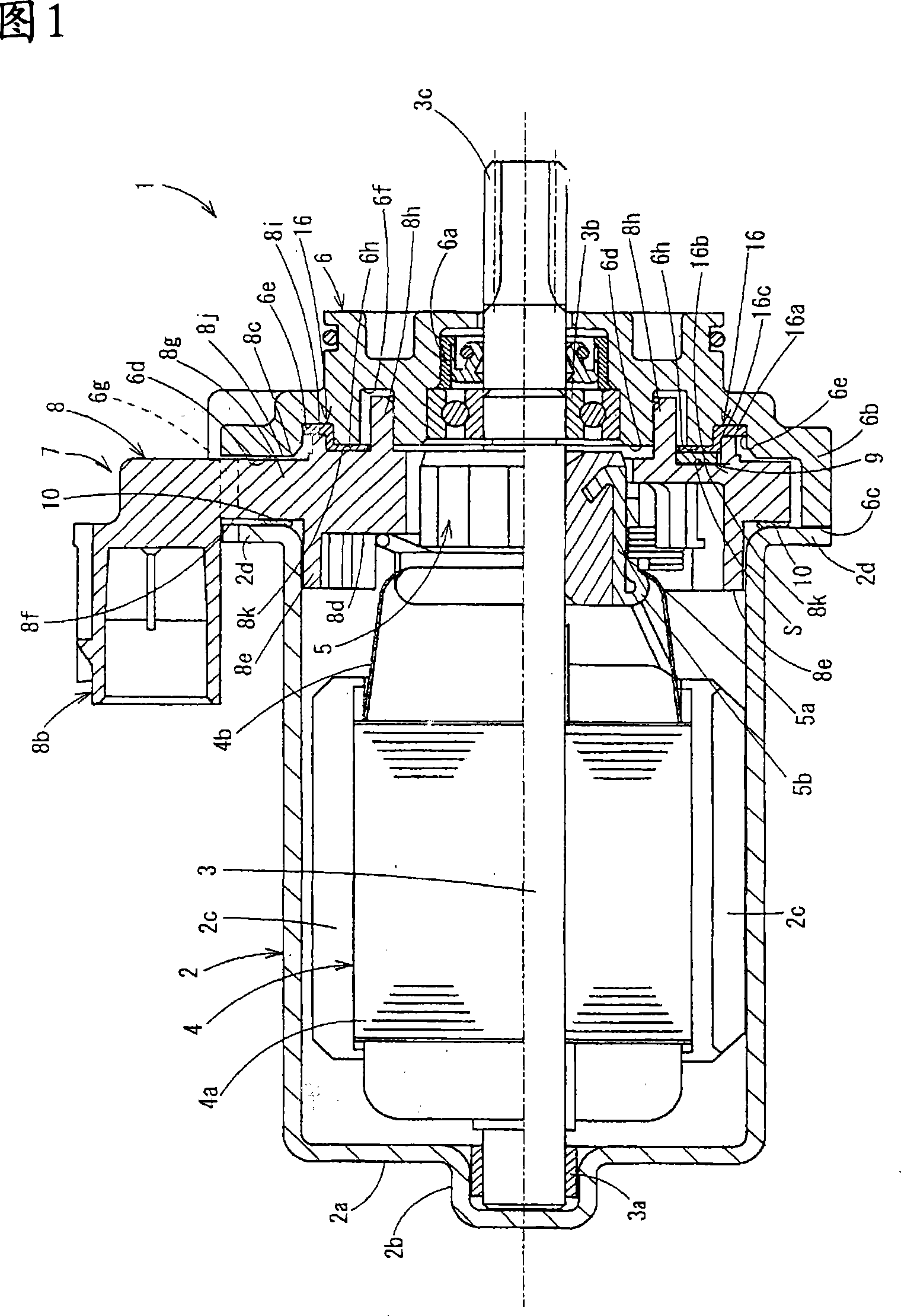

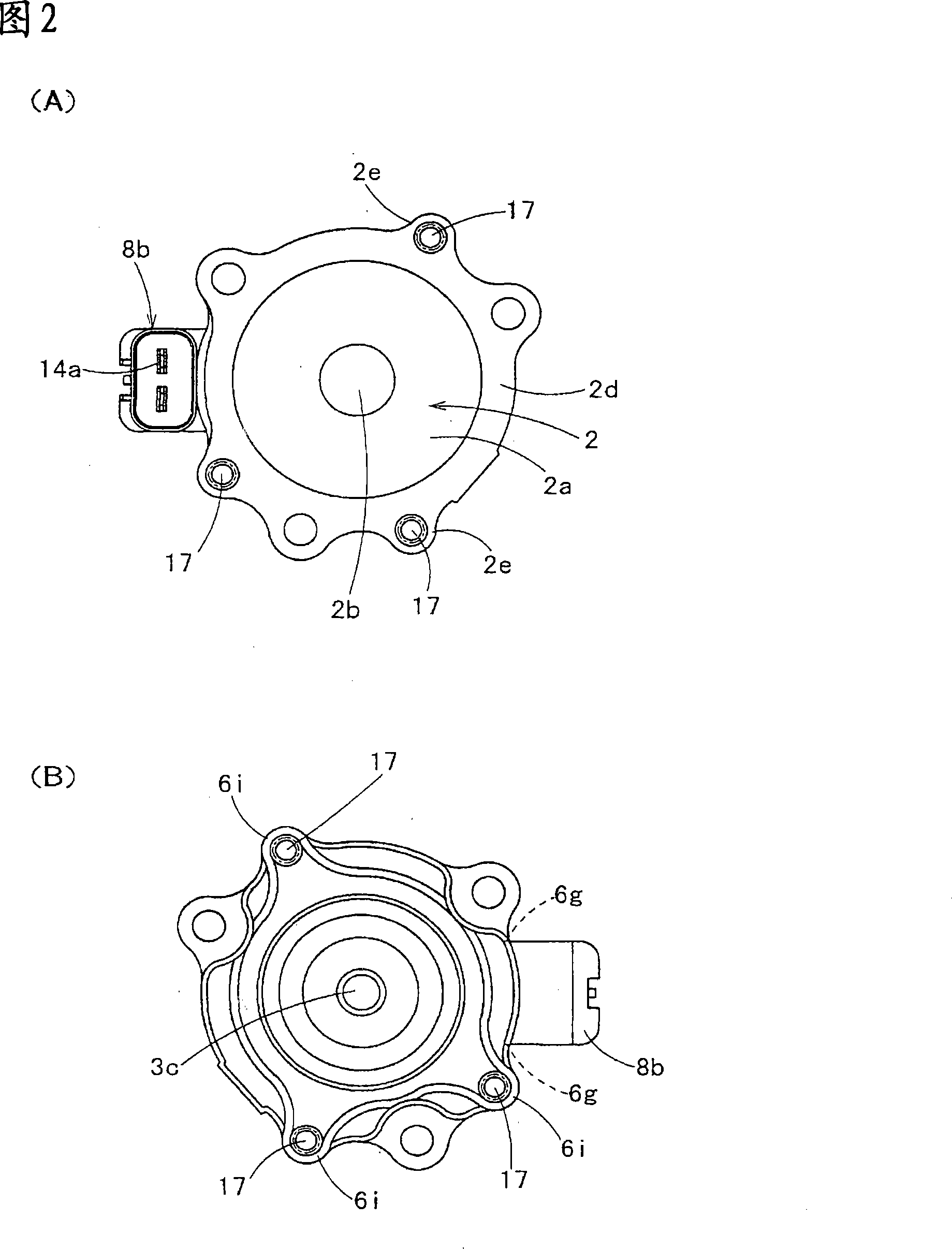

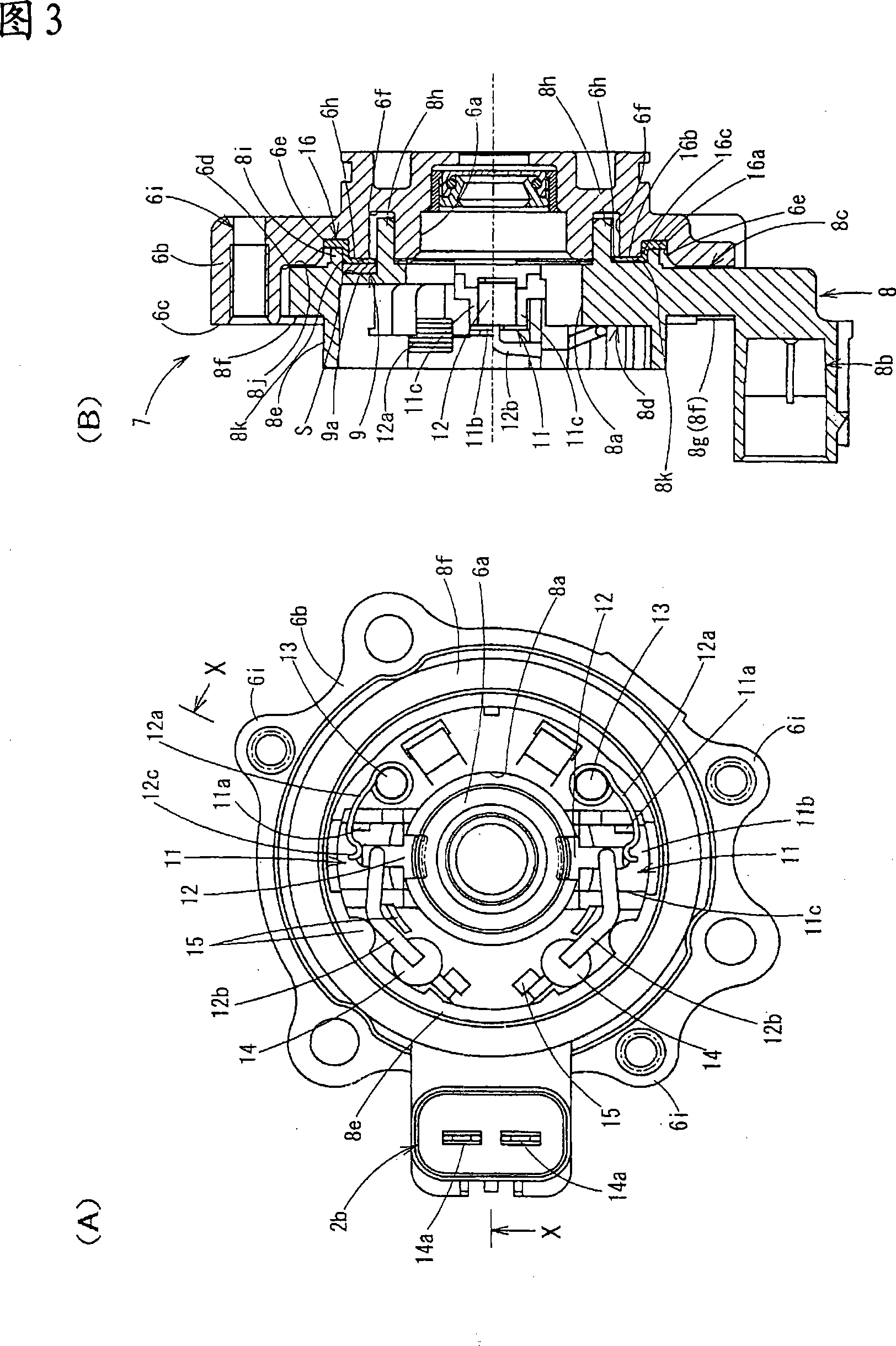

[0027] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0028] In the drawing, reference numeral 1 denotes an electric motor constituting an electronic component mounted on a vehicle. A bearing portion 2b is formed on a cylindrical bottom portion 2a of a bottomed cylindrical yoke 2 constituting the electric motor 1, and passes over the bearing portion 2b. The base end portion of the motor shaft 3 is rotatably supported by the bearing 3a. A core 4 formed by laminating a plurality of core materials 4 a is integrally fitted to the motor shaft 3 , and a plurality of coils 4 b are wound around the core 4 . Further, the commutator 5 is integrally externally fitted to the motor shaft 3 so as to be located on the front end side of the coil 4 , and is provided in the circumferential direction on the commutator vertical pieces 5b of the plurality of commutator pieces 5a on the outer peripheral surface of the commutator 5 . , the ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com