Volume controlled rotary compressor air-breathing device

A rotary compressor and capacity control technology, which is applied to rotary piston machinery, rotary piston pumps, rotary piston/swing piston pump components, etc., can solve the problem of reduced refrigeration capacity, complex processing technology, high working noise, etc. problem, to achieve the effect of low working noise, simple processing and assembly process, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0041] Referring to Fig. 4, the first suction pipe 37 in the suction device of the capacity control rotary compressor is connected to a cylinder, which can be either an upper cylinder or a lower cylinder, and the other cylinder is connected to the through hole of the partition plate Connect to air intake.

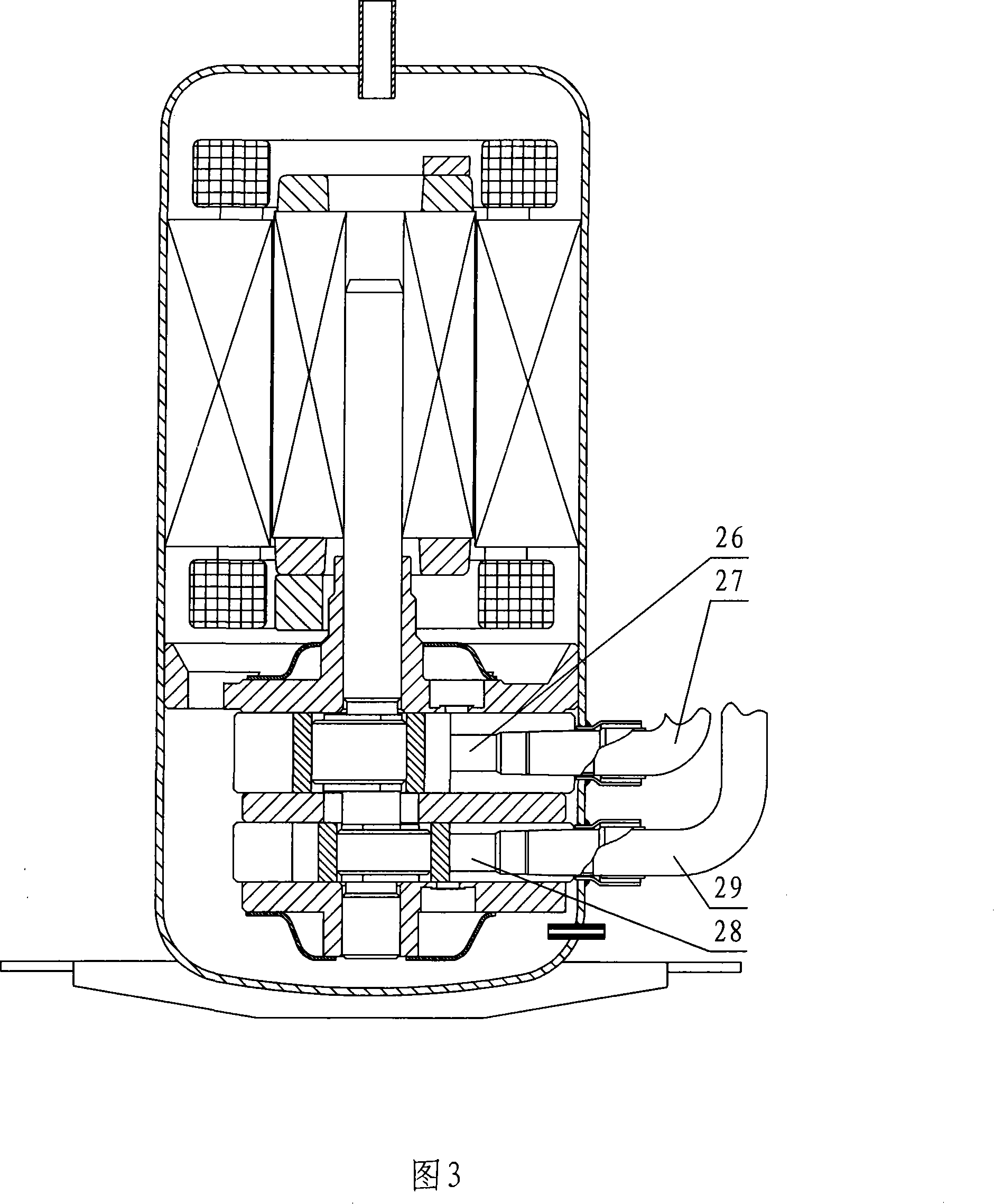

[0042] Referring to Figure 5, the first suction pipe 37 is connected to the upper cylinder, a part of the gas enters the upper cylinder through the upper suction hole 26, and the other part of the gas passes through the axial hole 31 of the upper cylinder, the partition through hole 30 on the partition and the lower cylinder in sequence. The upper first lower suction hole 28' enters the lower cylinder.

[0043] Referring to Figures 6-7, for a capacity-controlled rotary compressor, when the compressor operates at 100% capacity, both cylinders suck and compress. As mentioned earlier, a part of the gas enters the upper cylinder through the upper suction hole. Another part of ga...

no. 2 example

[0053] Referring to Fig. 19-Fig. 20, the second suction pipe 38 is first connected with the partition 25, and then connects with the upper and lower suction holes 36, the upper suction hole 26 or the lower suction hole 28 respectively through the partition board suction hole 36 and the lower suction hole 28 provided on the partition board. The two cylinders are connected. The gas under this structure has the shortest distance to reach the two cylinders, and both the two-stage variable capacity compressor and the three-stage variable capacity compressor can be used.

[0054] Referring to Fig. 21-Fig. 22, in order to reduce the resistance of the gas in the flow process, wedge-shaped cutouts 34 or a combination of wedge-shaped cutouts 34 and cylinder axial holes 35 are respectively set on the path from the diaphragm suction hole 36 to the upper and lower cylinders. The angle α of the notch is between 30° and 90°, including 30° and 90°, wherein the wedge-shaped notch 34 and the ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com