Water-bath type liquefied natural gas evaporator

A liquefied natural gas, water bath technology, applied in the direction of pressure vessels, fixed-capacity gas storage tanks, container discharge methods, etc., can solve the problems of small vaporization, incoherent gas supply, large volume, etc., to avoid pipeline blockage, Easy installation and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

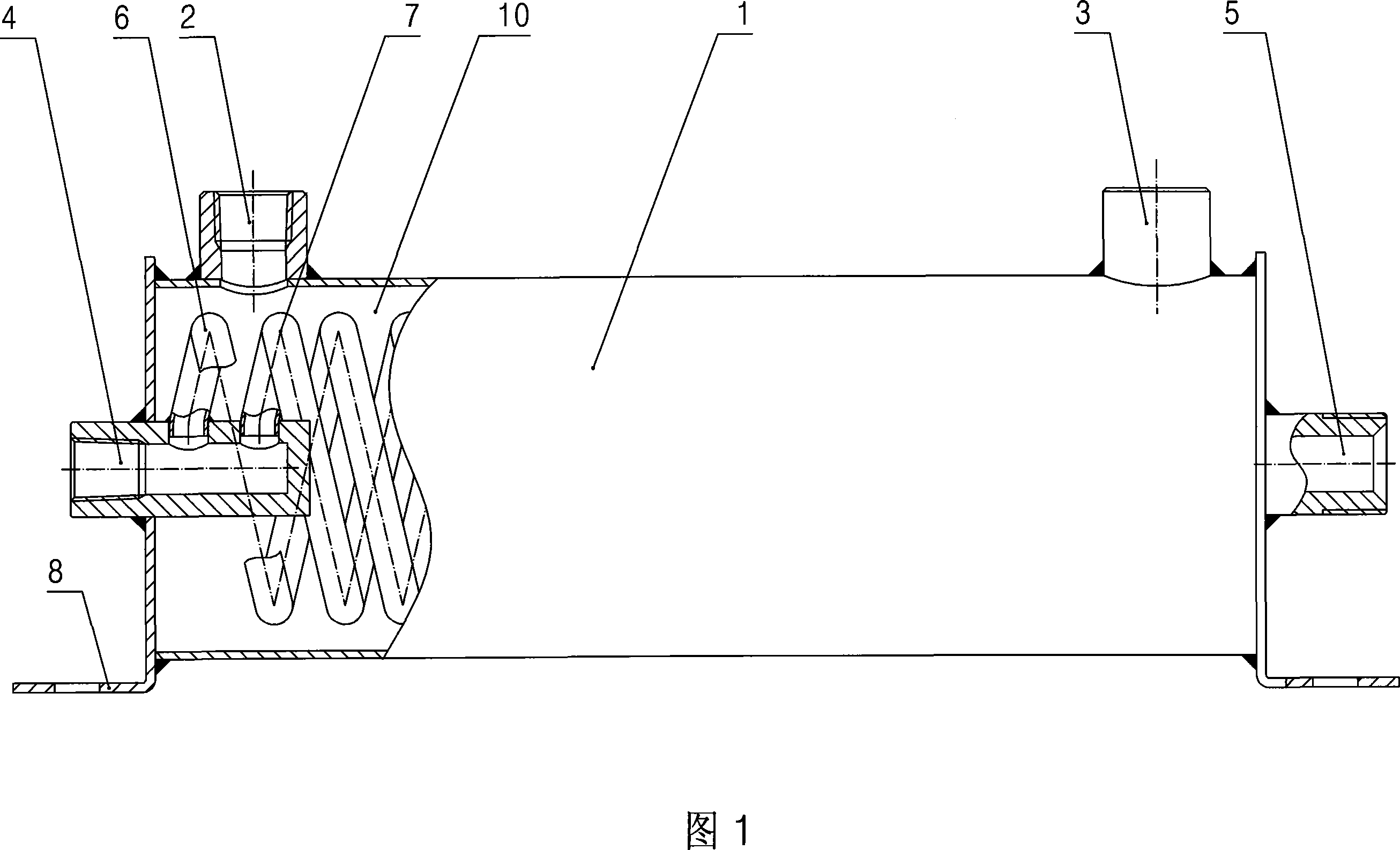

[0010] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0011] As shown in Figure 1, the water bath type liquefied natural gas vaporizer of the present invention includes: a water bath type cylinder 1, a closed heat exchange cavity 10 is built in the water bath type cylinder 1, and the water bath type cylinder 1 is provided with a The inlet and outlet ports 2 and 3 of the heat chamber 10 communicate with each other. The heat exchange chamber 10 is provided with two spiral heat exchange tubes 6 and 7 that are wound together. The two ends of the heat exchange tube 6 are connected to each other. The vaporized natural gas inlet 4 and the natural gas outlet 5 at the two ends of the water bath cylinder 1 are connected, and the two ends of the heat exchange tube 7 are respectively connected with the vaporized natural gas inlet 4 and the natural gas outlet 5 that pass through the two ends of the water bath c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com