Digital control machining operation error prevention technology

A technology of operating errors and CNC machining machine tools, applied in digital control, electrical program control, etc., can solve problems such as reduction, huge loss, and economic loss of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

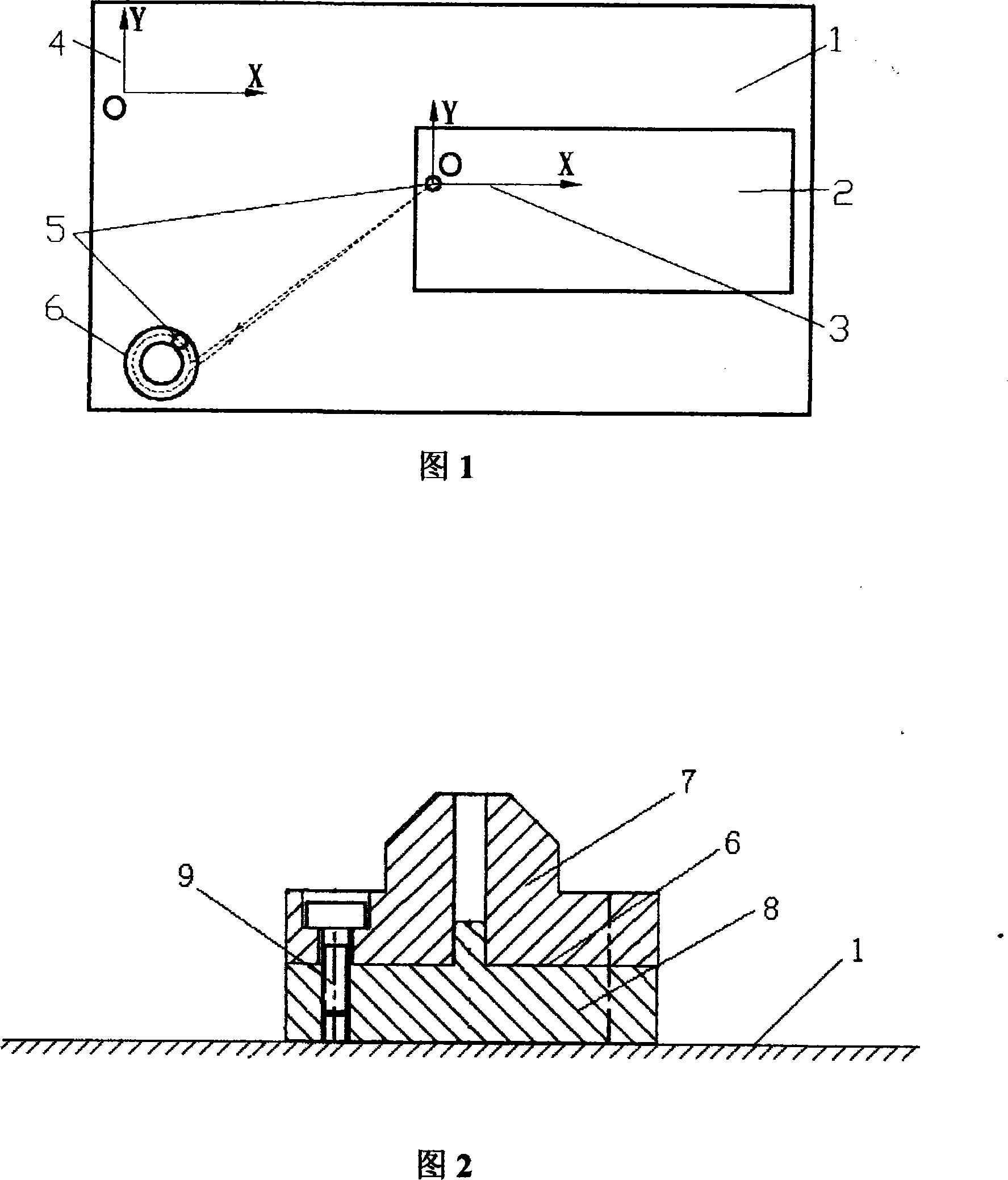

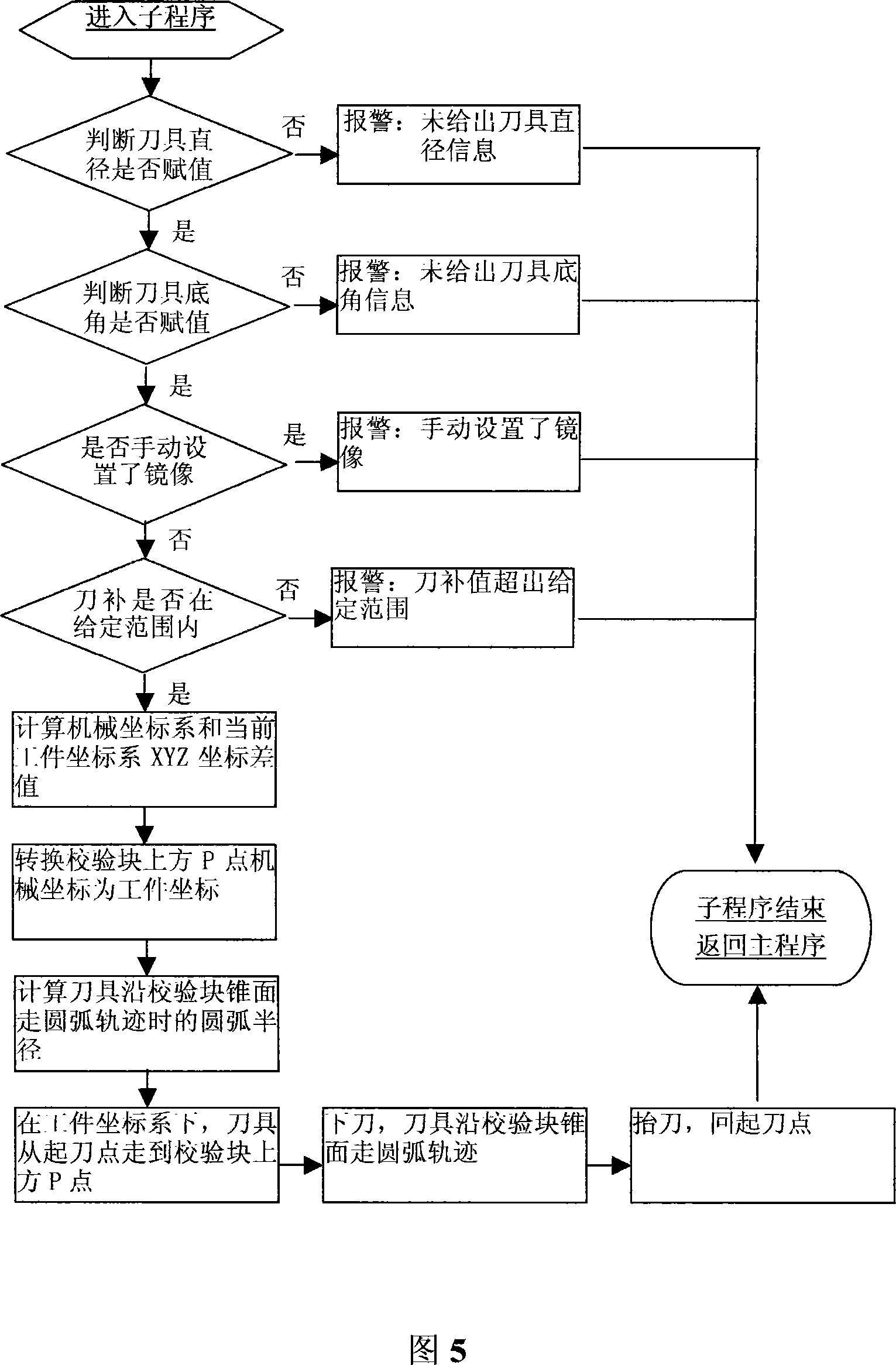

[0015] Referring to accompanying drawing 1, with respect to the machine tool workbench 1 of numerical control processing machine tool, machine tool coordinate system 4 is constant, and workpiece coordinate system 3 changes with the change of workpiece 2 to be processed, check block 6 is fixed on the machine tool workbench 1 is a replaceable tapered standard block. The coordinate value of the check block in the machine tool coordinate system 4 is a constant fixed value. The position of the check block 6 in the workpiece coordinate system 3 can be determined by the system parameter Call to realize the conversion from the machine coordinate system to the workpiece coordinate system.

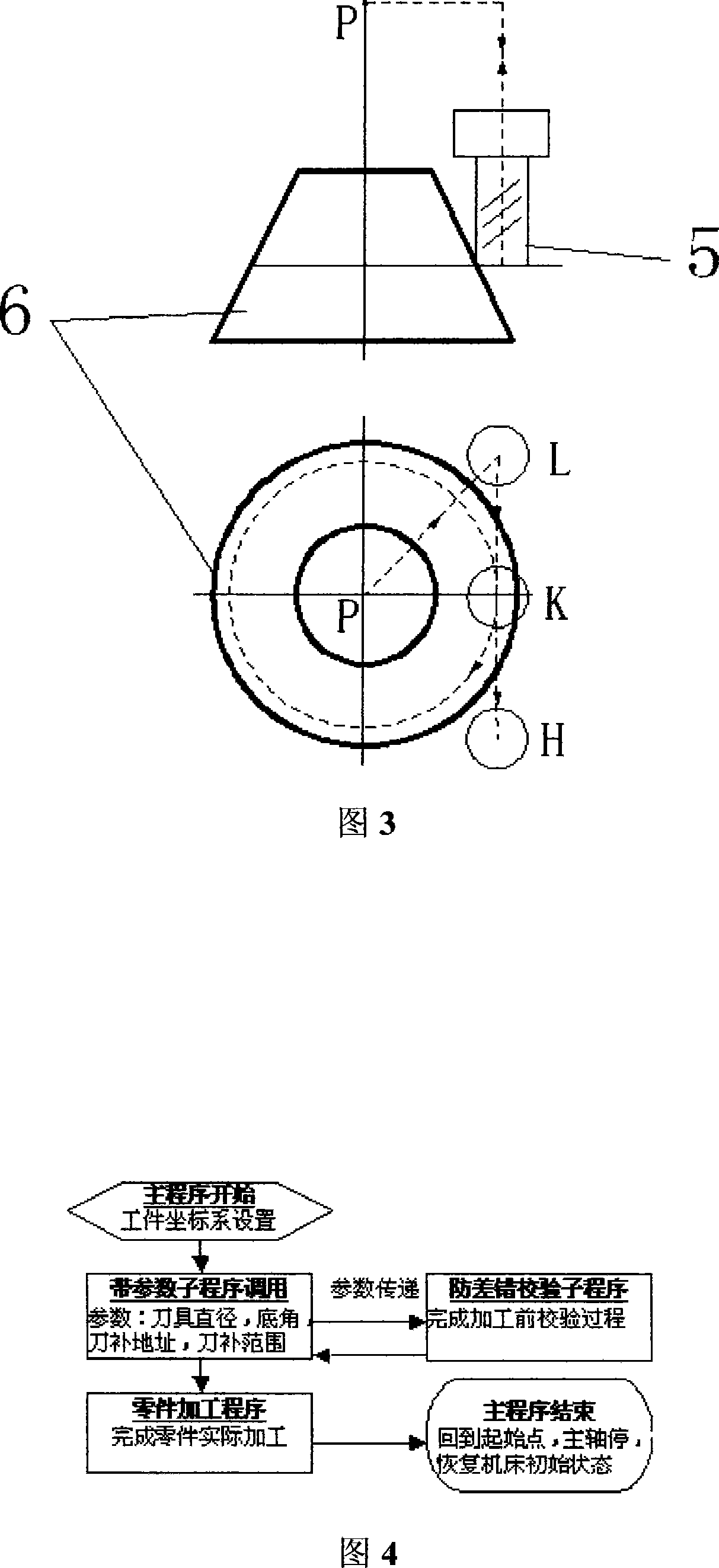

[0016] Before the CNC machining system executes the part processing program, after setting the workpiece coordinate system, it first calls the error prevention check program to make the machining tool 5 move along the tapered surface of the error check block 6 for inspection, and determine the use sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com