Dewatering control method for washing machine

A control method and technology of a laundry device, applied to the control device of a washing machine, a washing device, textiles and papermaking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

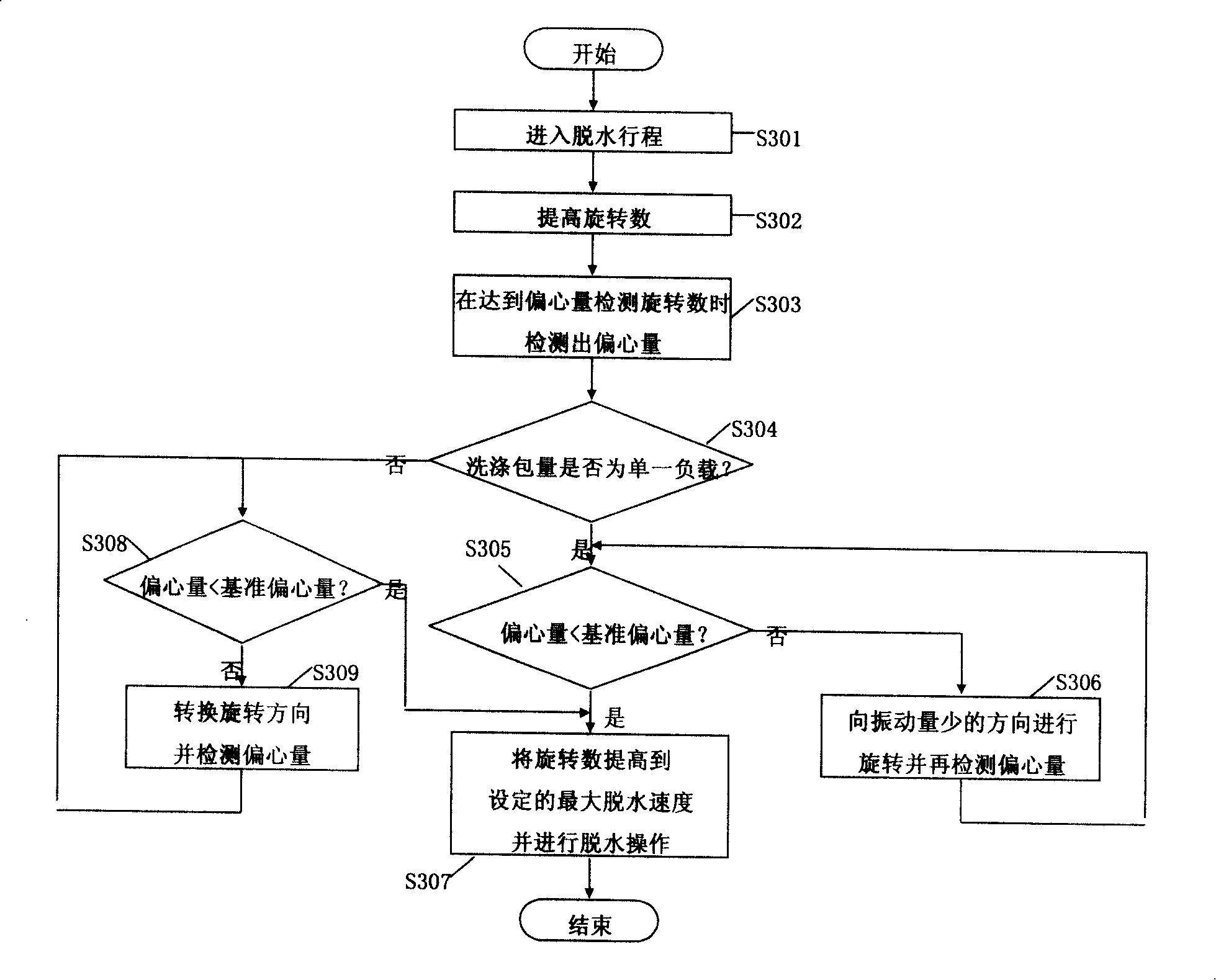

[0036] The basic technical idea of the present invention is that, when the detected eccentricity does not reach the reference range, under normal load, the rotation direction will be changed and the eccentricity will be detected again; Rotate in the same direction, and then detect the amount of eccentricity and perform dehydration operation, so that under the single load condition with large eccentricity, the vibration of the system can be minimized.

[0037] That is, in the case of a general load, during the re-detection operation of the eccentricity amount, the rotation direction is switched, and the eccentricity amount detection step is performed; Rotate in one direction, and repeat the step of re-detecting the amount of eccentricity.

[0038] like image 3 As shown, when the amount of washing bags is detected and the dehydration process is entered (S301), the rotation speed of the drum motor is increased, thereby increasing the rotation speed of the drum (S302).

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com