Buckling device of radiator

A technology for radiators and joints, which is applied in the direction of elastic/clamping devices, instruments, and cooling of instruments, and can solve problems such as adjusting the fastening force of radiator fastening devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

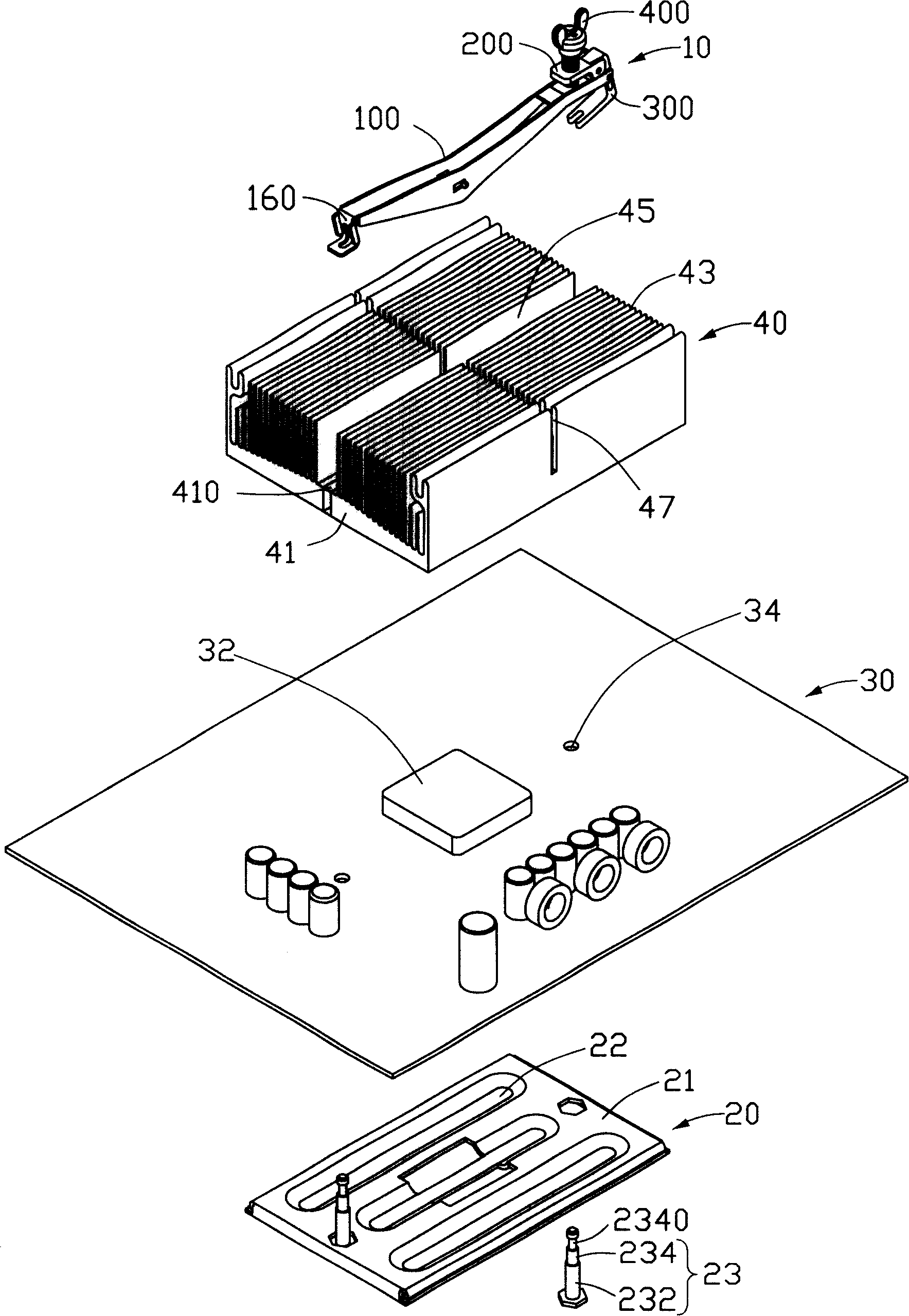

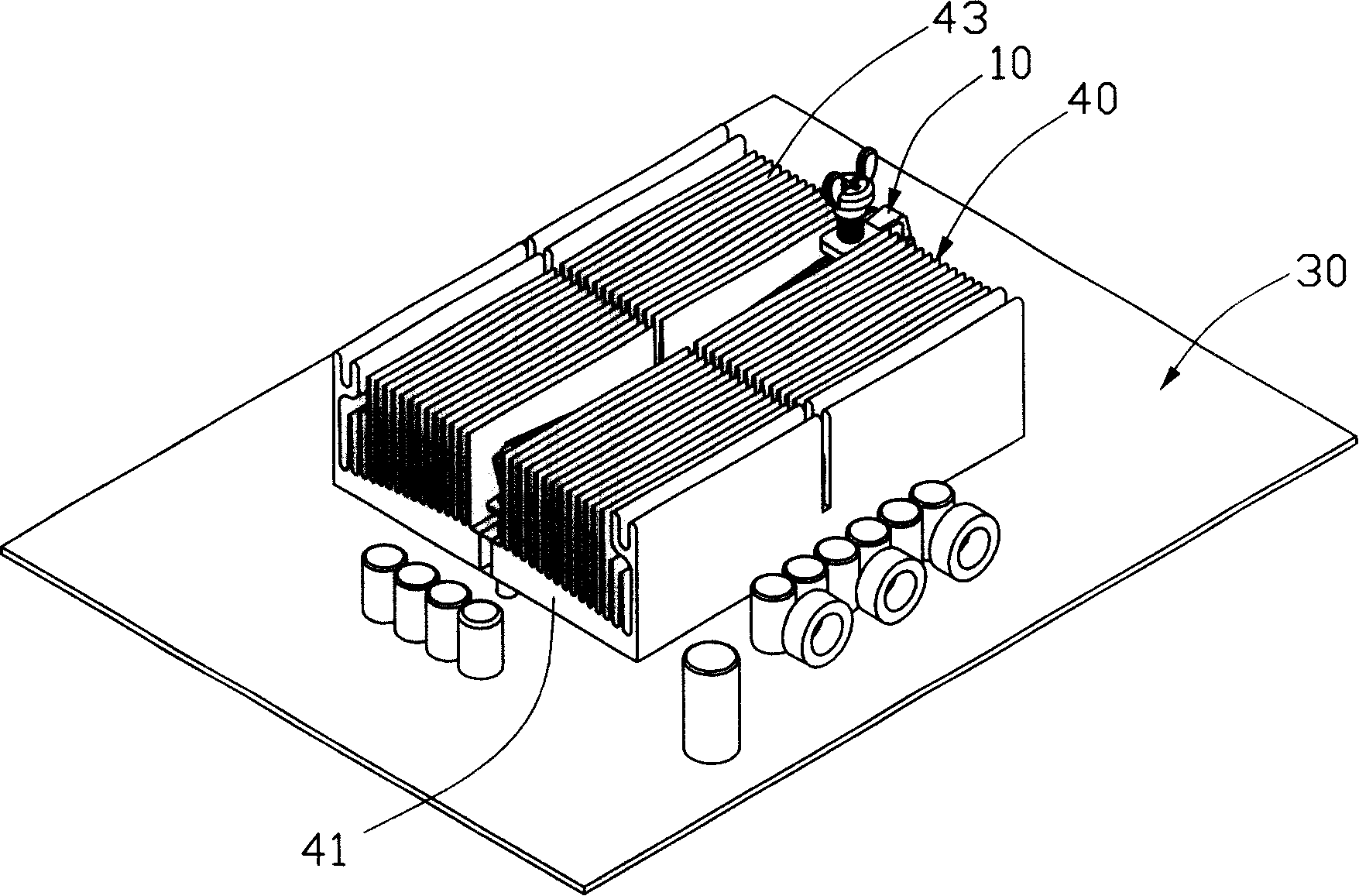

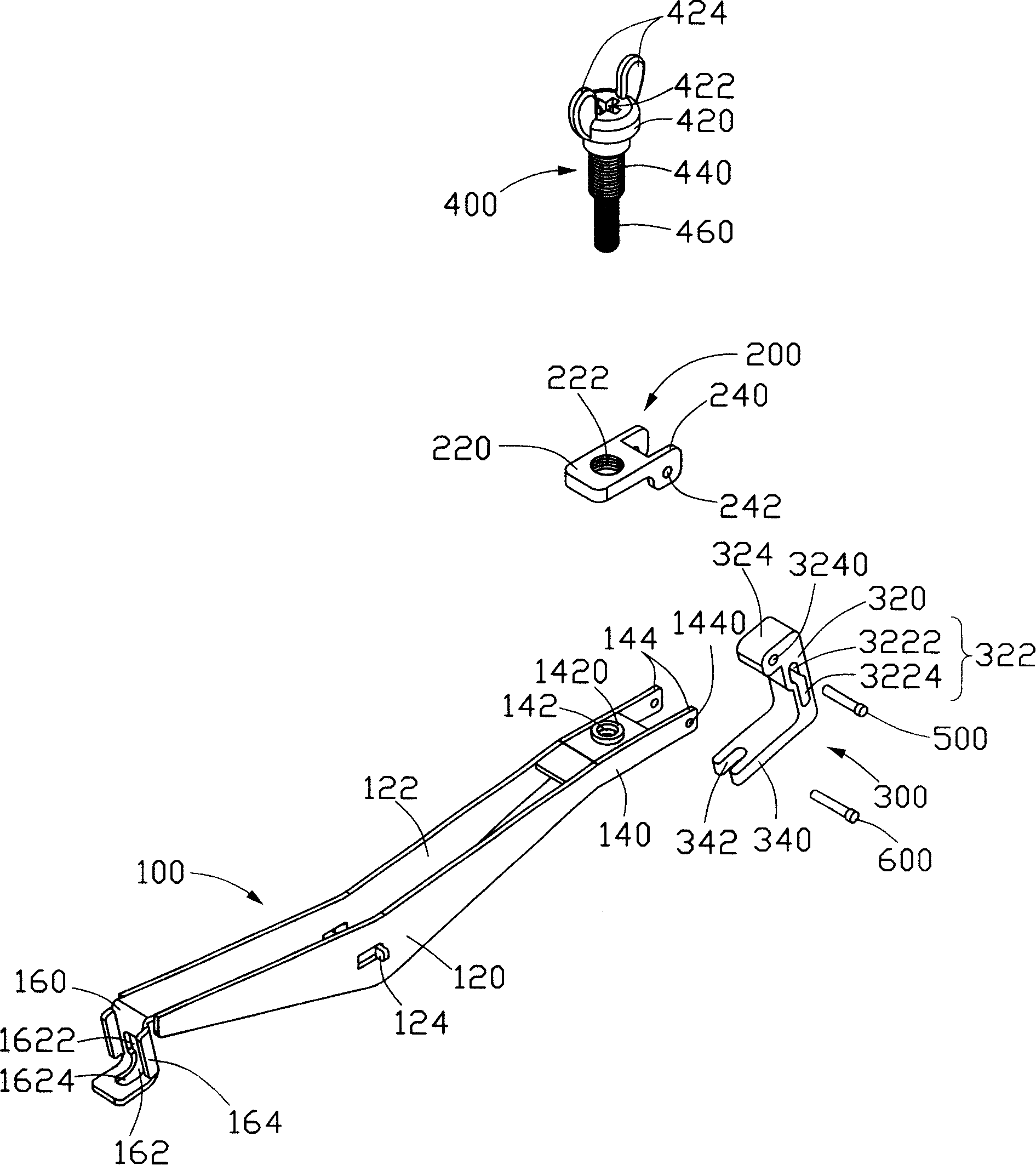

[0015] see Figure 1 to Figure 2 , the radiator fastening device 10 in one embodiment of the present invention is used to fix the radiator 40 on the circuit board 30, the radiator fastening device 10 straddles the radiator 40 and is located on the back of the circuit board 30. Plate 20 fits.

[0016] The circuit board 30 is mounted with a heating electronic component 32 , and has circular installation holes 34 respectively located outside two ends of the electronic component 32 .

[0017] The heat sink 40 is made of metal materials with good thermal conductivity such as aluminum, copper, etc., and it includes a base plate 41 that is in contact with the top surface of the electronic component to absorb the heat generated by the operation of the electronic component and a number of heat sinks that are arranged in parallel on the base plate 41. Cooling fins 43, a long slot 45 is provided in the middle of these cooling fins 43 to accommodate the radiator fastening device 10, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com