Mashed potatoes machine for short-order

A potato and mashed machine technology, applied in application, food preparation, food science, etc., can solve the problems of single finished product, customers cannot see the processing process, low efficiency, etc., and achieve high work efficiency, novel design, economical and practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

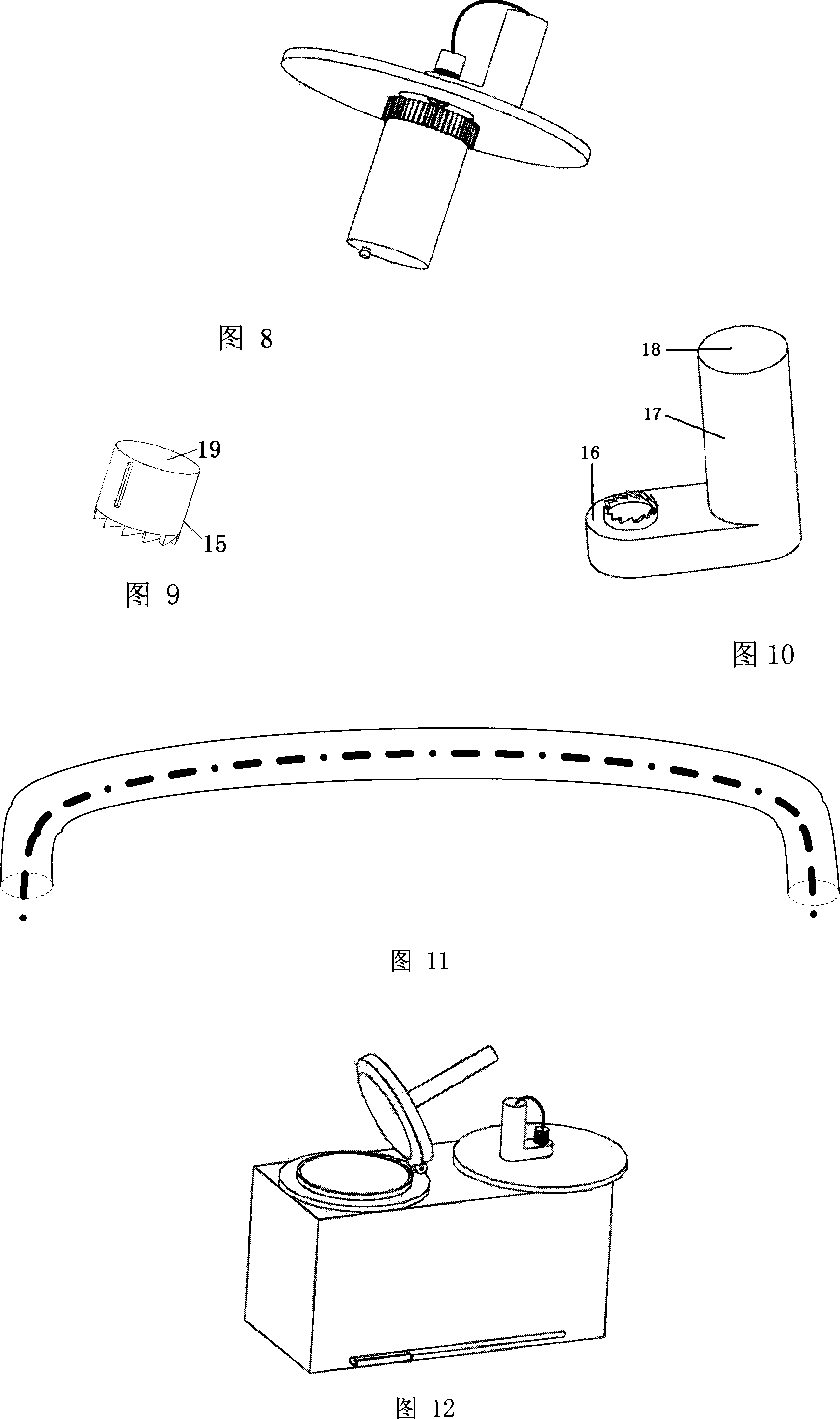

[0024] Below in conjunction with accompanying drawing 1-12 and embodiment do further description:

[0025] A mashed potato machine for fast food mainly includes a base, a machine body, a slide plate, a cutting cavity and a feeding rotary cavity.

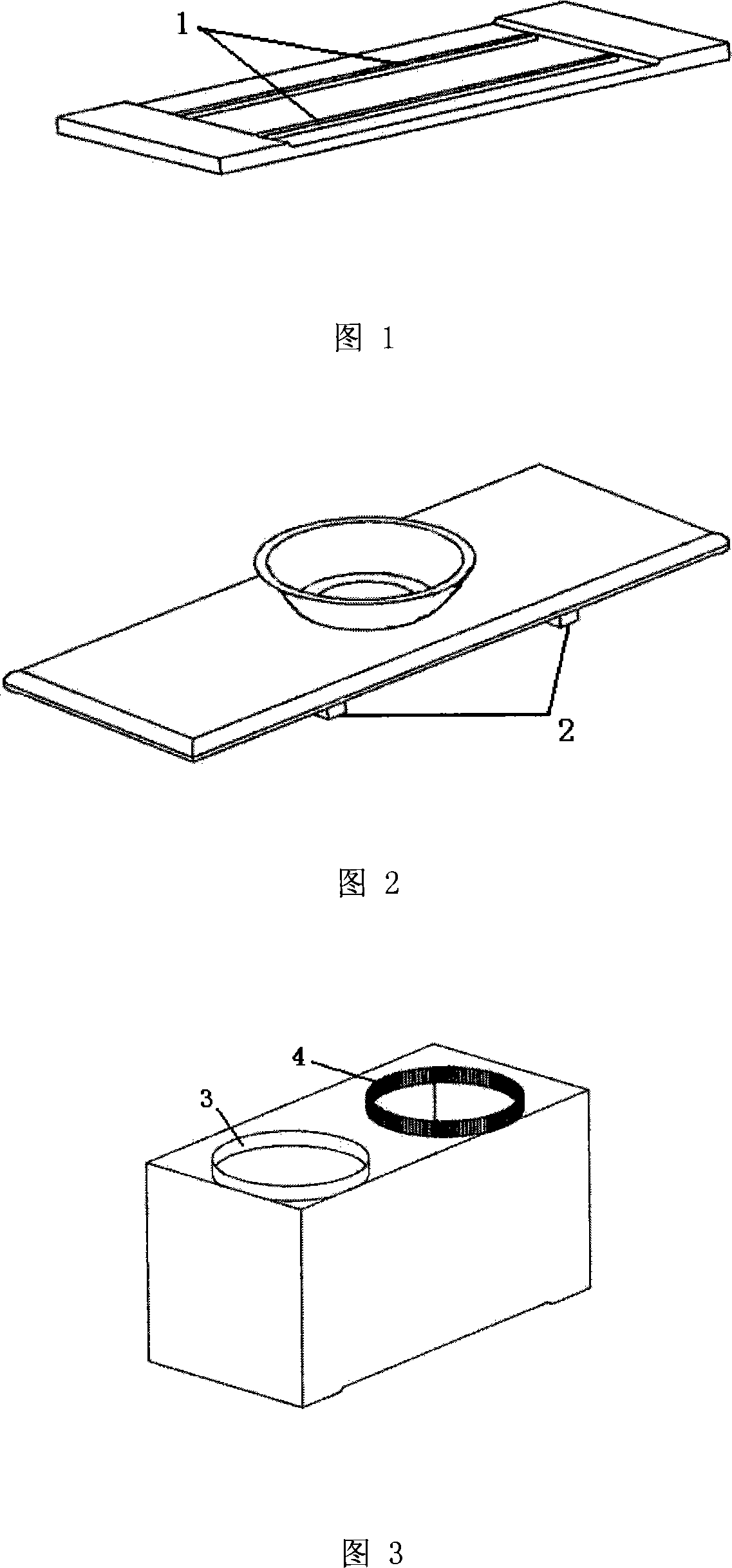

[0026] The base is a rectangular flat plate with a rectangular groove, and a chute 1 is arranged in the groove.

[0027] There is a rectangular groove corresponding to the base groove at the bottom of the body, and a rectangular slide plate is arranged in the space formed by the base and the groove of the body, and a slide rail 2 corresponding to the base chute is arranged on the plate. A smooth side hole 3 and a toothed side hole 4 are provided on the top surface of the body.

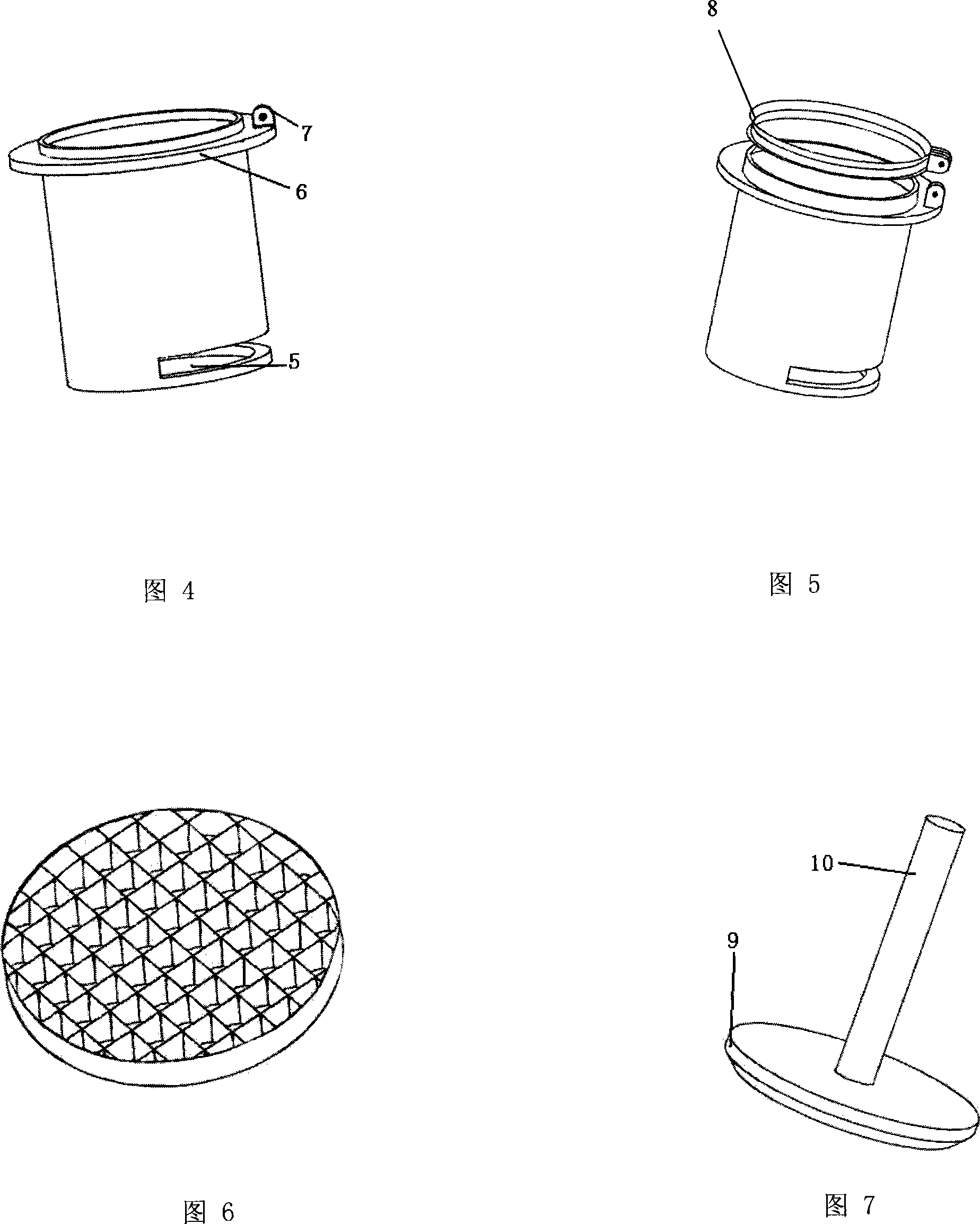

[0028] The cutting cavity is a barrel-shaped cavity set in the smooth edge hole 3 of the body. The lower part of the cavity is provided with a slot 5 for inserting the blade. The blade surface of the blade is grid-shaped, and different shapes can be selected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com