Assistant plumbago inner lining for semi-continuous casting aluminum alloy cake electromagnetic field

An electromagnetic field and aluminum alloy technology is applied in the field of graphite lining for aluminum alloy flat ingot electromagnetic field assisted semi-continuous casting, which can solve the problems of frequent replacement and achieve the effects of reducing induction heating, improving utilization rate, and small friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

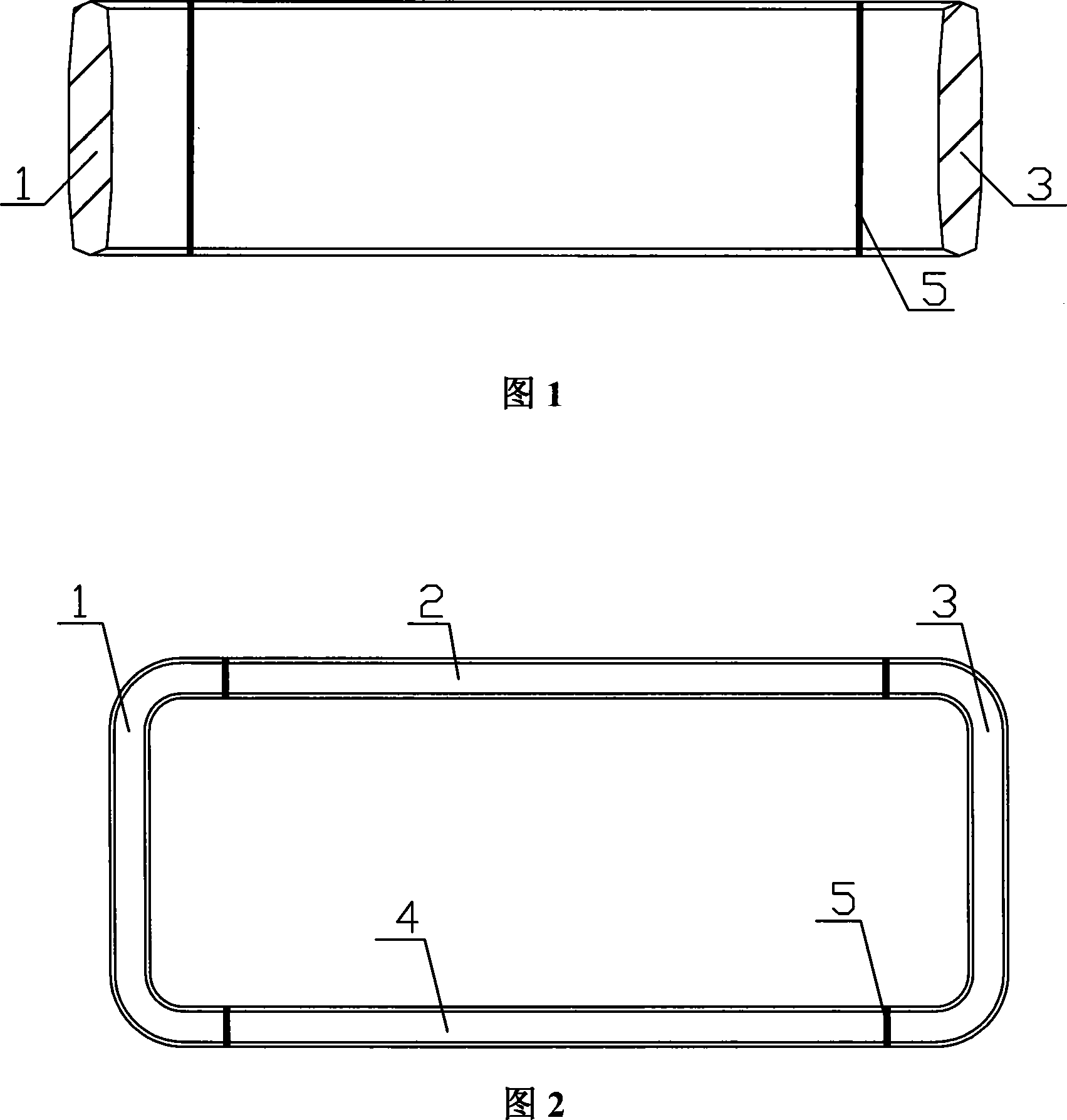

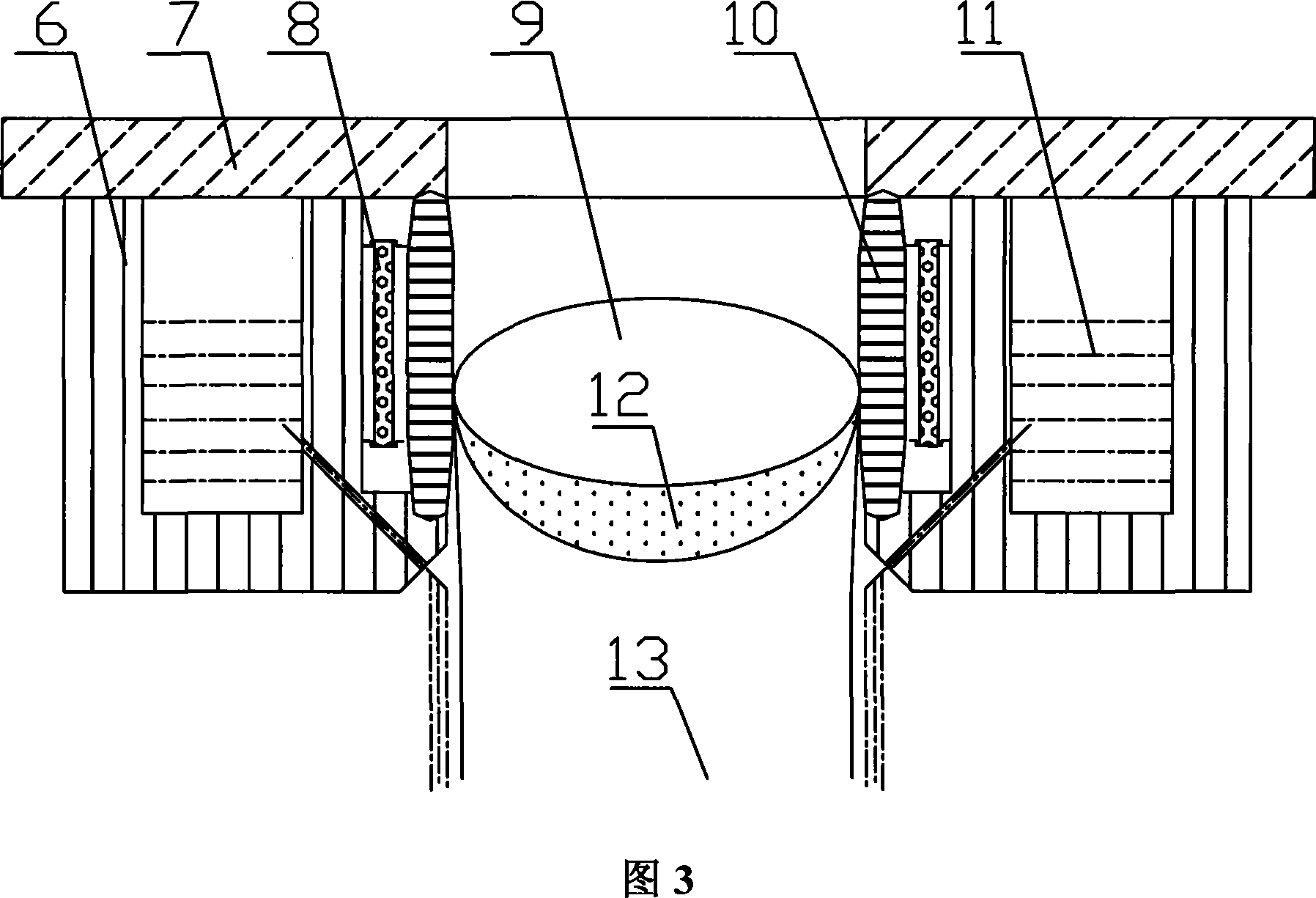

[0019] As shown in Figure 1 and Figure 2, a graphite lining for electromagnetic field-assisted semi-continuous casting of an aluminum alloy flat ingot consists of four pieces of graphite on the front side 4, graphite on the back side 2, graphite 1 on the left side, and graphite 3 on the right side It is made of graphite, and mica sheets 5 are respectively arranged at the joints of adjacent graphite; the graphite lining has a symmetrical structure up and down, and the inner wall of the graphite lining has a taper, and the taper angle is 173°~178°; the upper and lower end surfaces of the graphite lining are respectively Designed with a card slot.

[0020] The graphite lining adopts a split structure, which is designed as a rectangle according to the shape of the flat ingot. An insulating layer is set at the junction of adjacent graphite to block the loop of the graphite lining and prevent the entire graphite lining from forming a ring induction under the action of an electromagne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com