High-voltage transformer having injection molding insulation member

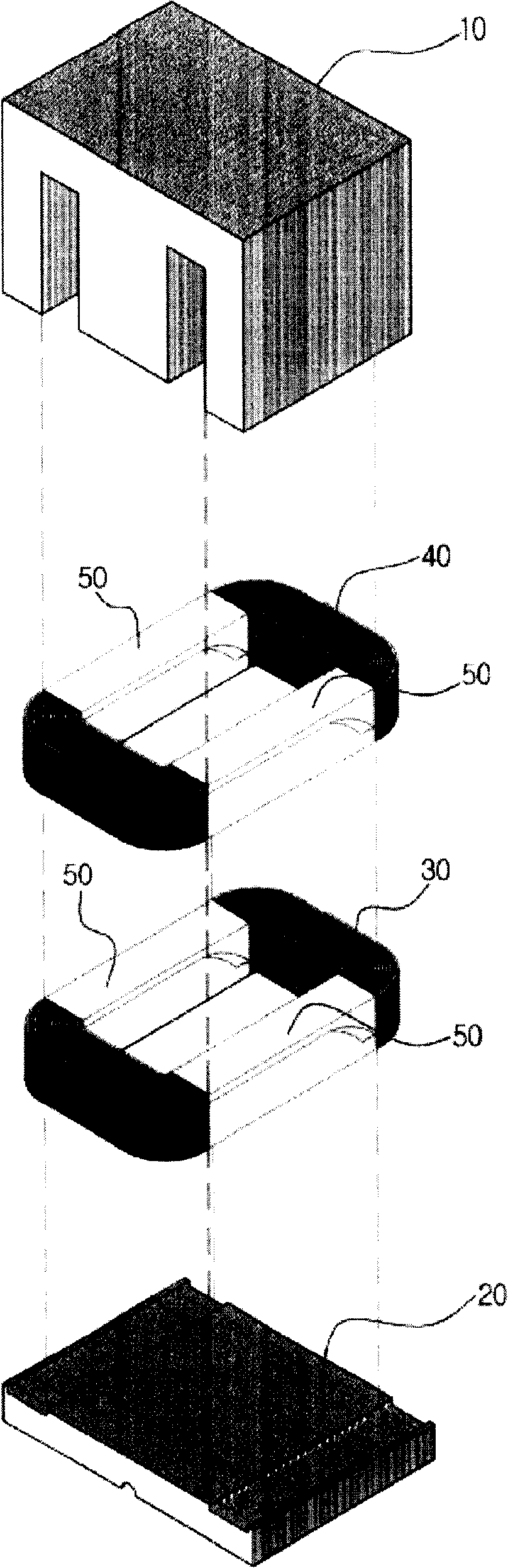

A high-voltage transformer and injection molding technology, which is applied in the field of high-voltage transformers, can solve the problems of complicated covering operation of primary coil 30 and secondary coil 40, performance degradation of high-voltage transformer, and production efficiency, so as to omit the bonding process, prevent damage, The effect of reducing the number of processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

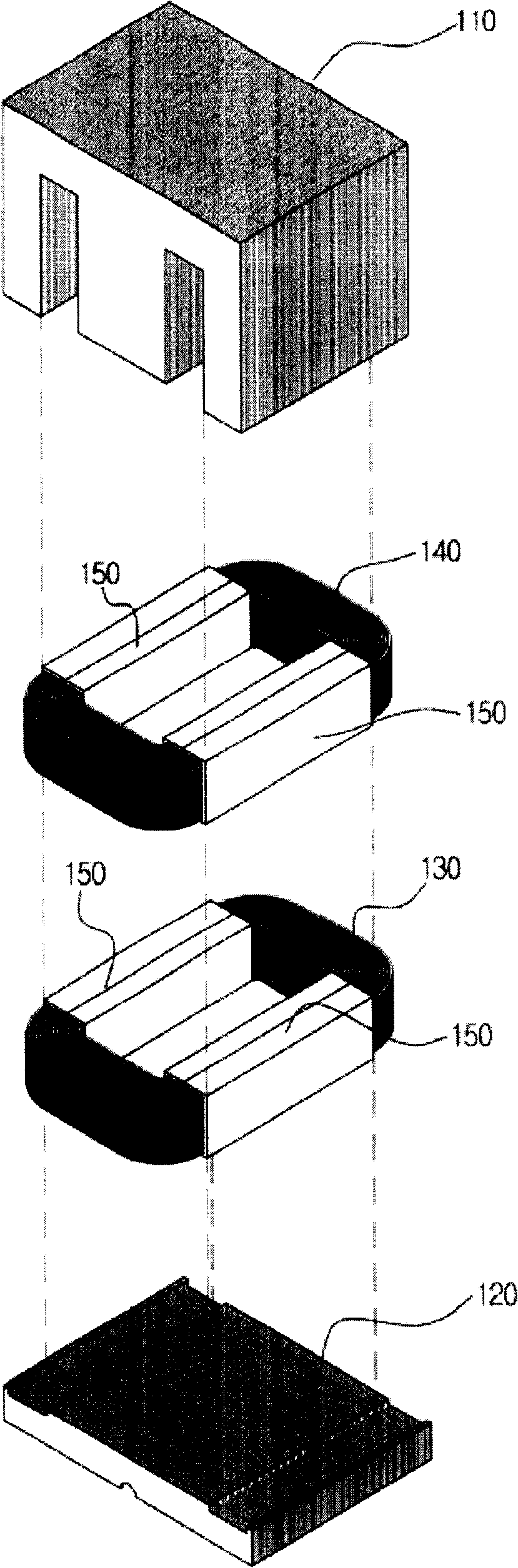

[0019] Such as figure 2 As shown, the present invention includes an E-shaped magnetic core unit 110. The E-shaped magnetic core unit 110 is configured with a primary coil 130 and a secondary coil 140 through winding, and an injection-molded insulating member 150 is used to cover the primary coil 130 and the secondary coil. 140 on.

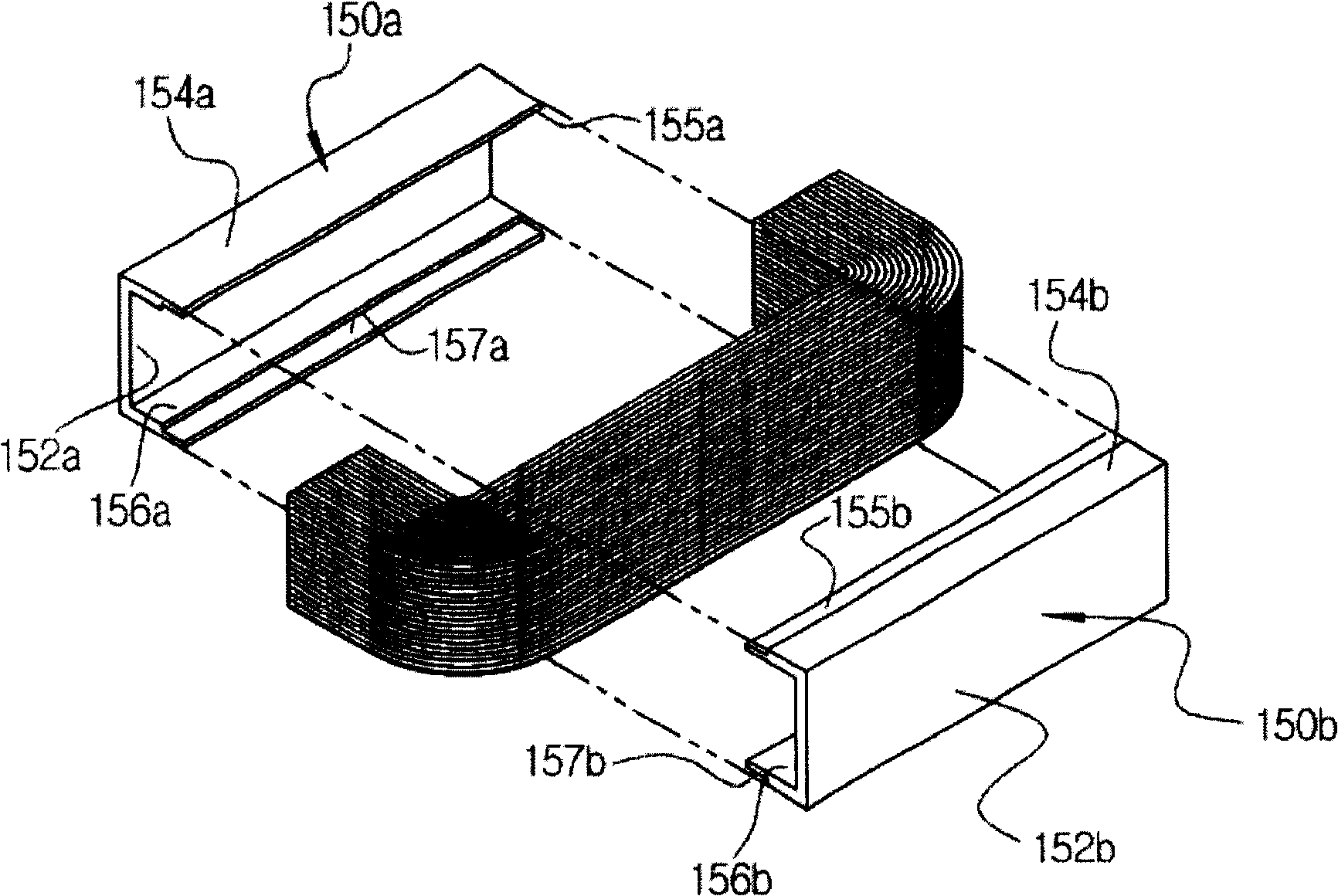

[0020] The material of the aforementioned injection molding insulating part 150 is PBT (Polybutylene Terephthalate) with good ductility, tensile force and strength, which is made of such as image 3 The shown U-shaped first insulator 150a and the second insulator 150b are combined with each other.

[0021] The central portion of the first insulator 150a is equipped with a side plate 152a with a thickness of 0.5mm and a length of 10mm. The upper end of the side plate 152a is an upper plate 154a with a thickness of 0.5mm and a length of 15m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com