Method for manufacturing luminous HDMI connector

A manufacturing method and connector technology, which is applied to the parts, connections, and electrical components of the connection device, can solve the problems of no fixed distribution area, prone to failure, and blind maintenance, so as to save time and manpower and ensure work Status, Ease of Service Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

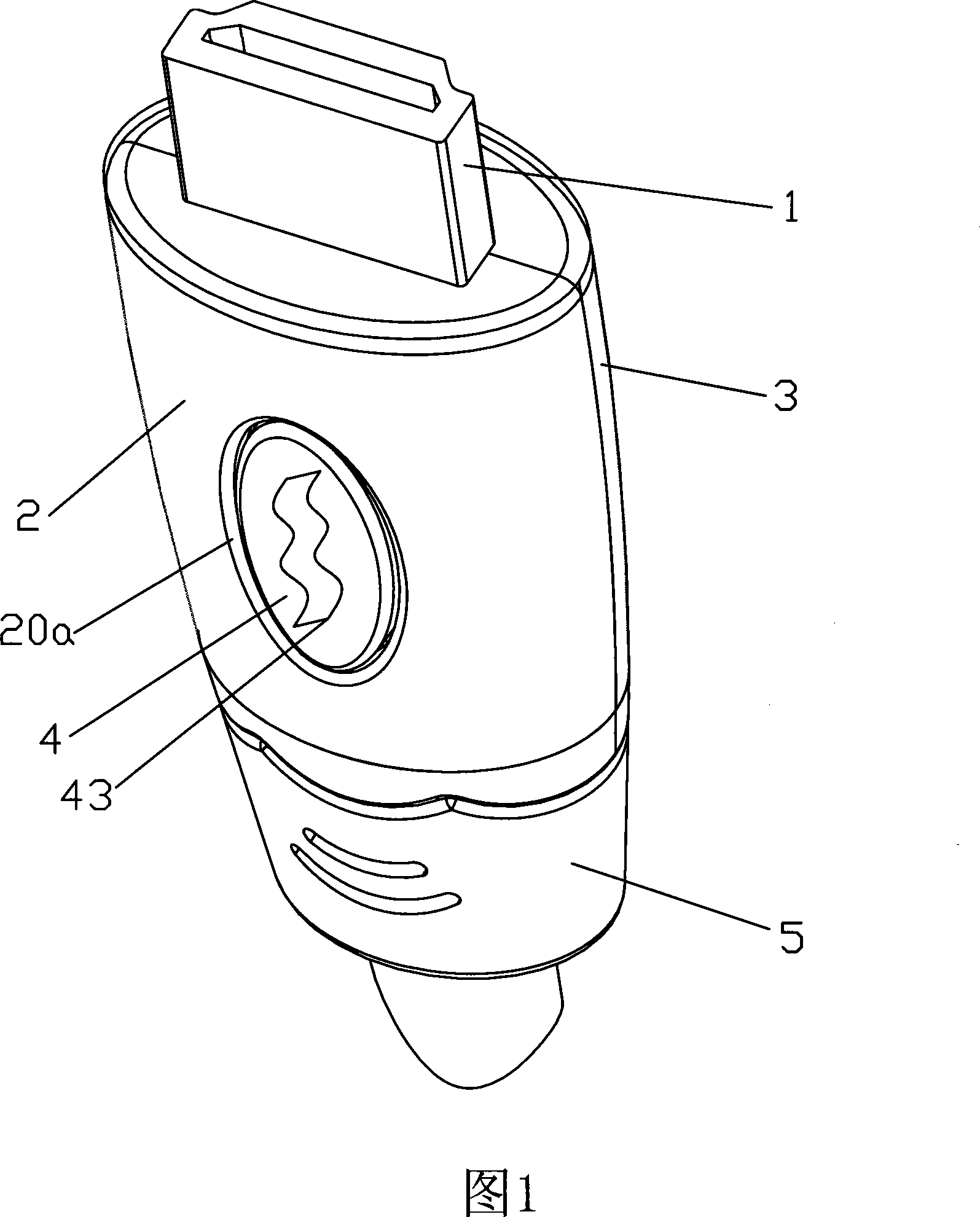

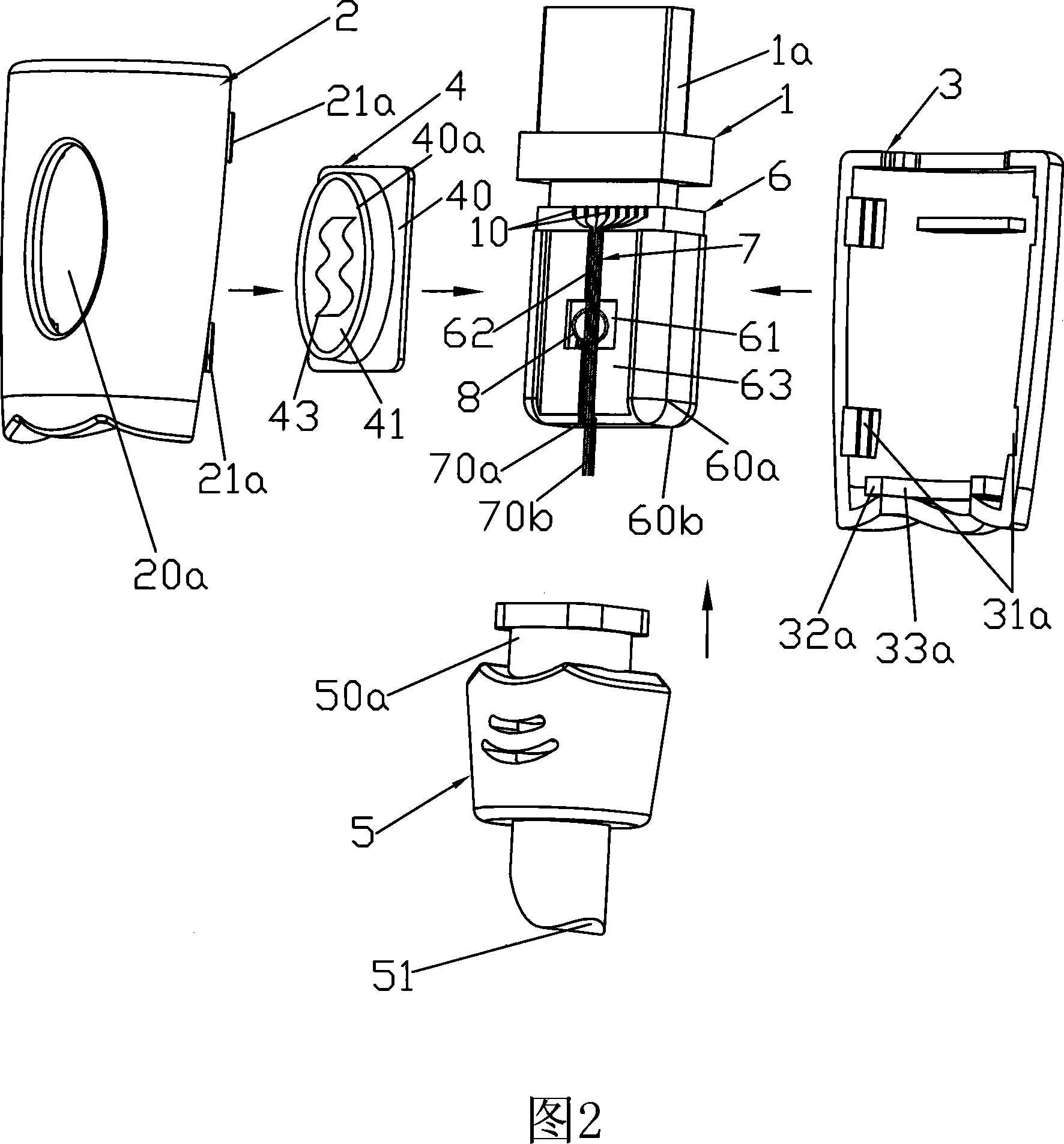

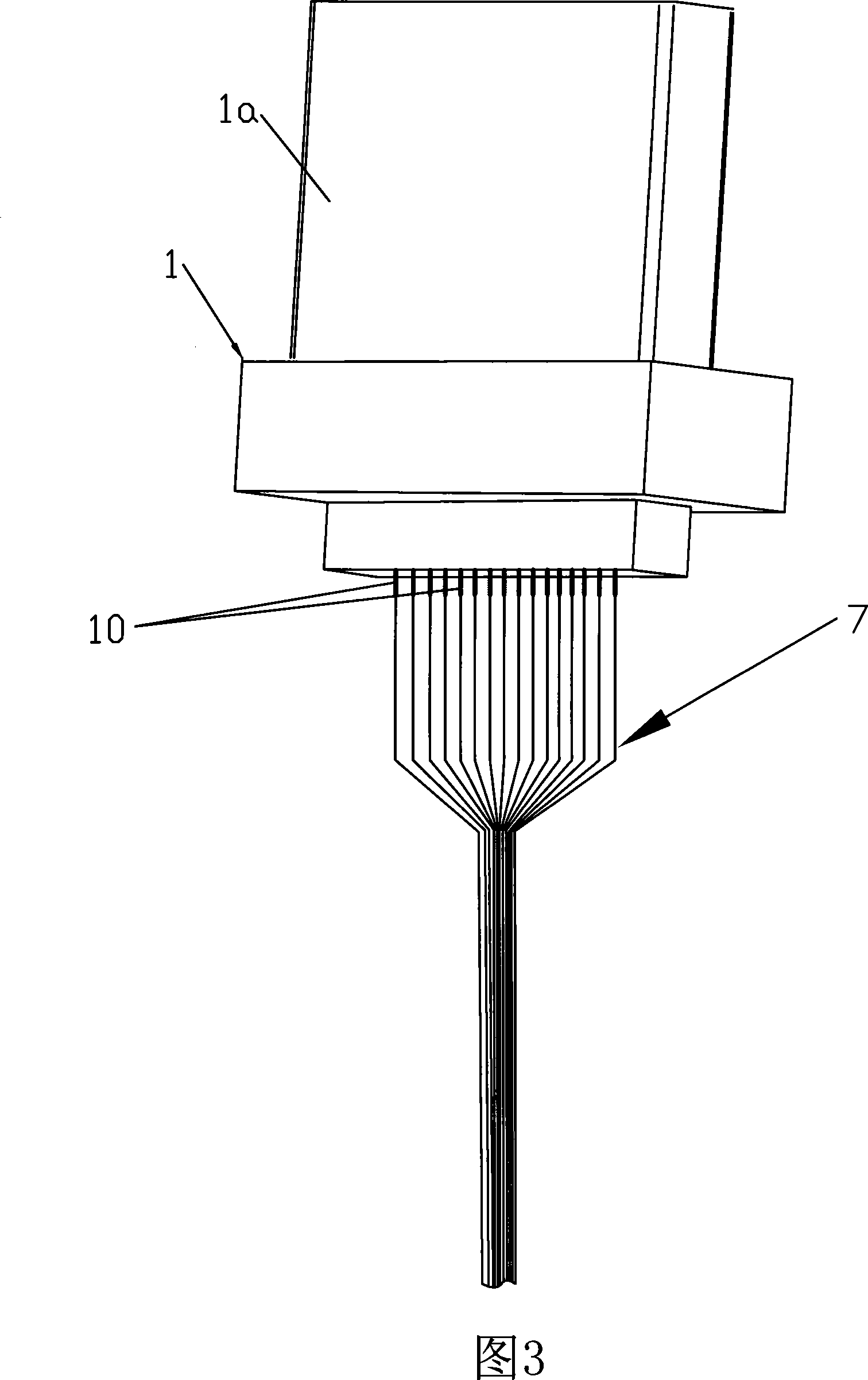

[0032] As shown in Figure 1 and Figure 2, the luminous HDMI connector of the present invention includes a plug body 1, the front end of the plug body 1 has a docking portion 1a that is docked with an external socket, an inner mold 6 is formed at the rear end, and a plurality of conductive terminals 10 penetrates the docking part 1 and is exposed from the rear end to connect with a wire 7 respectively, wherein the inner mold 6 has a wire groove 62 and a lamp hole 61, and the wire 7 is accommodated in the wire groove 62 of the inner mold 6 Inside, the wire 7 includes an indicator light connection line 70a and a device connection line 70b; the plug connector also includes an indicator light 8, a flexible output tube 5 and an outer shell, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com