Sealing structure for container and cap used for the same

A container sealing and cover technology, which is applied in the direction of containers, sealing, flexible containers, etc., can solve the problems of difficult to peel off sealing materials, can not absorb the rise of internal pressure, etc., and achieve the effect of preventing peeling and high sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

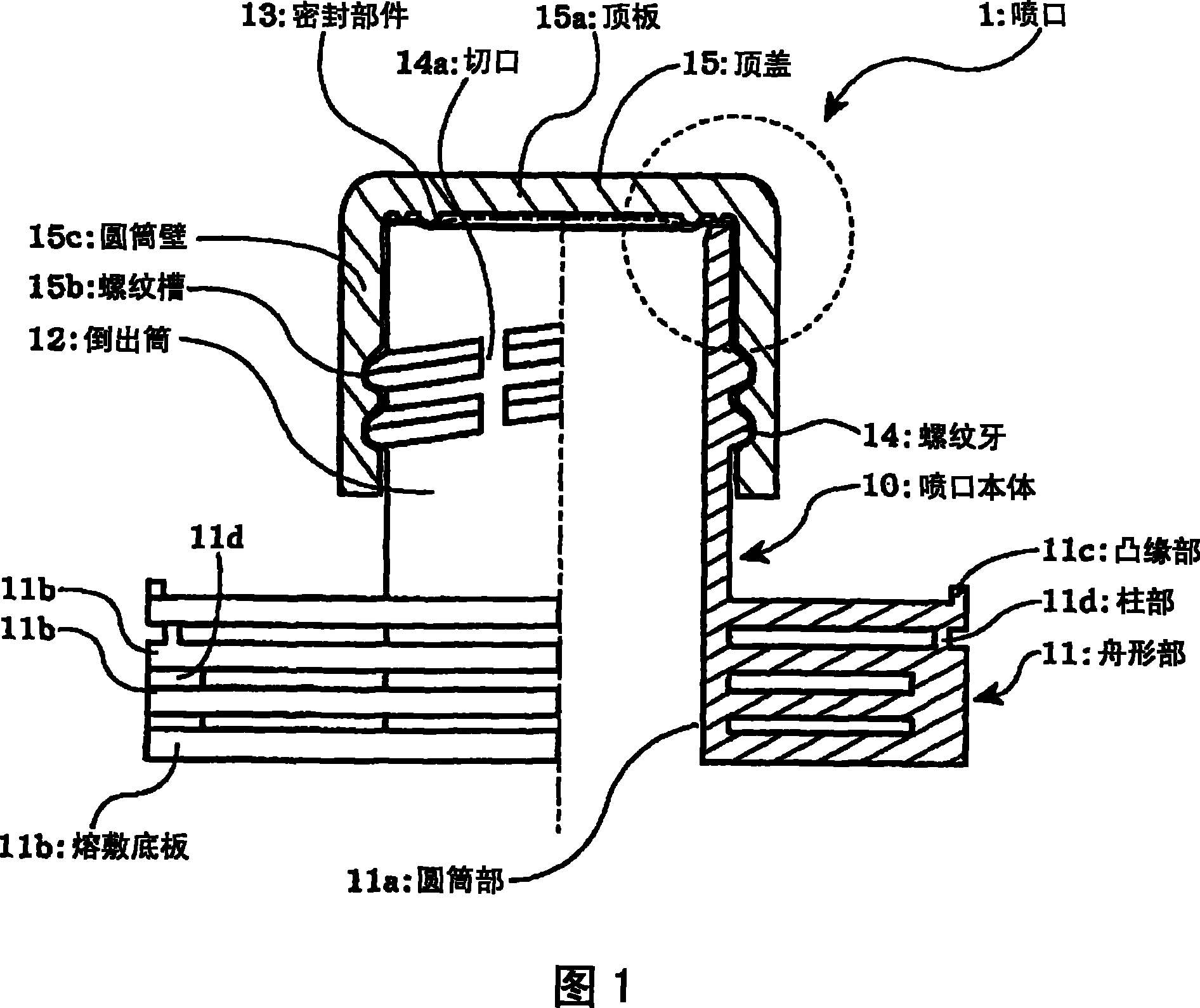

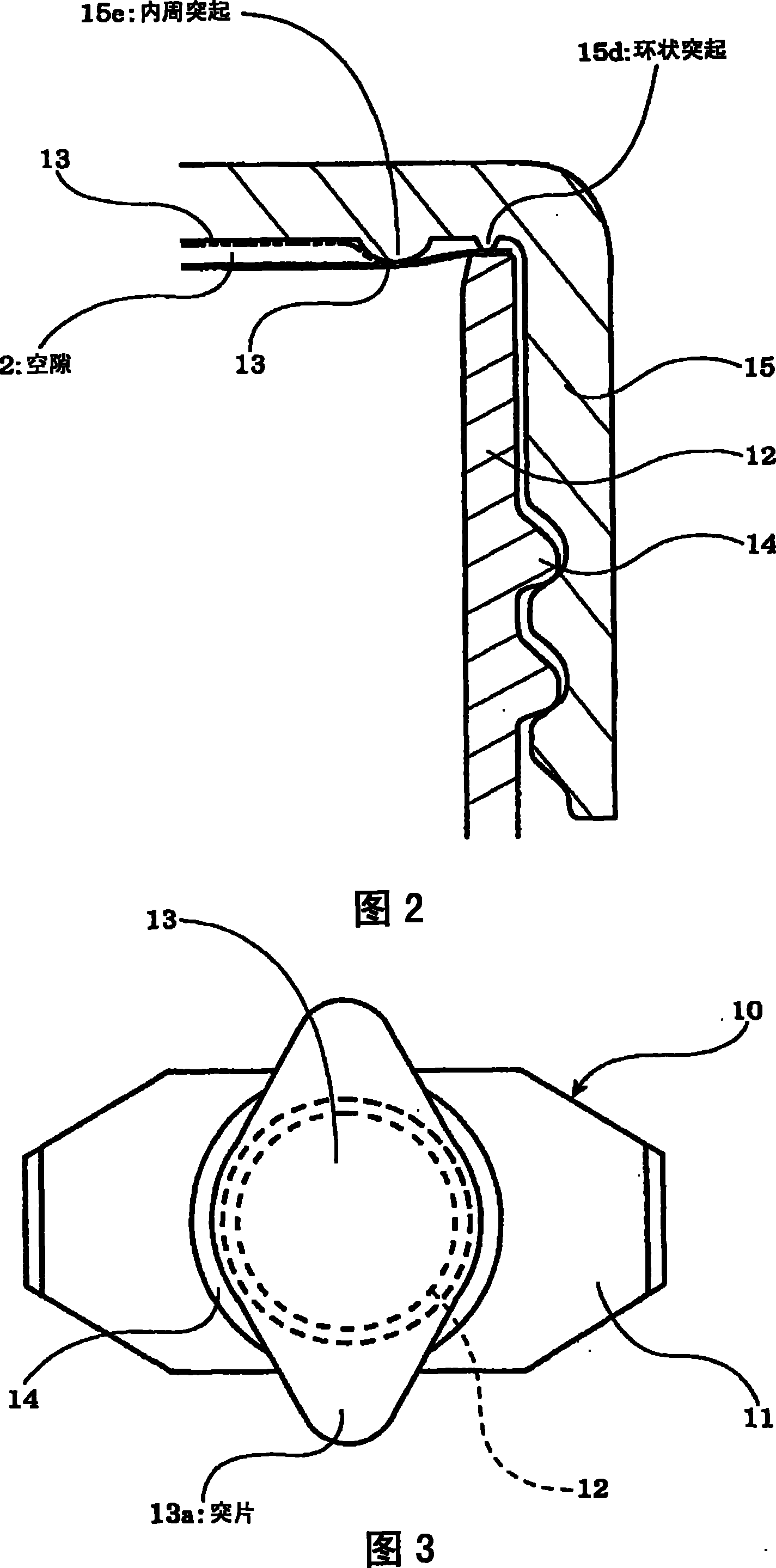

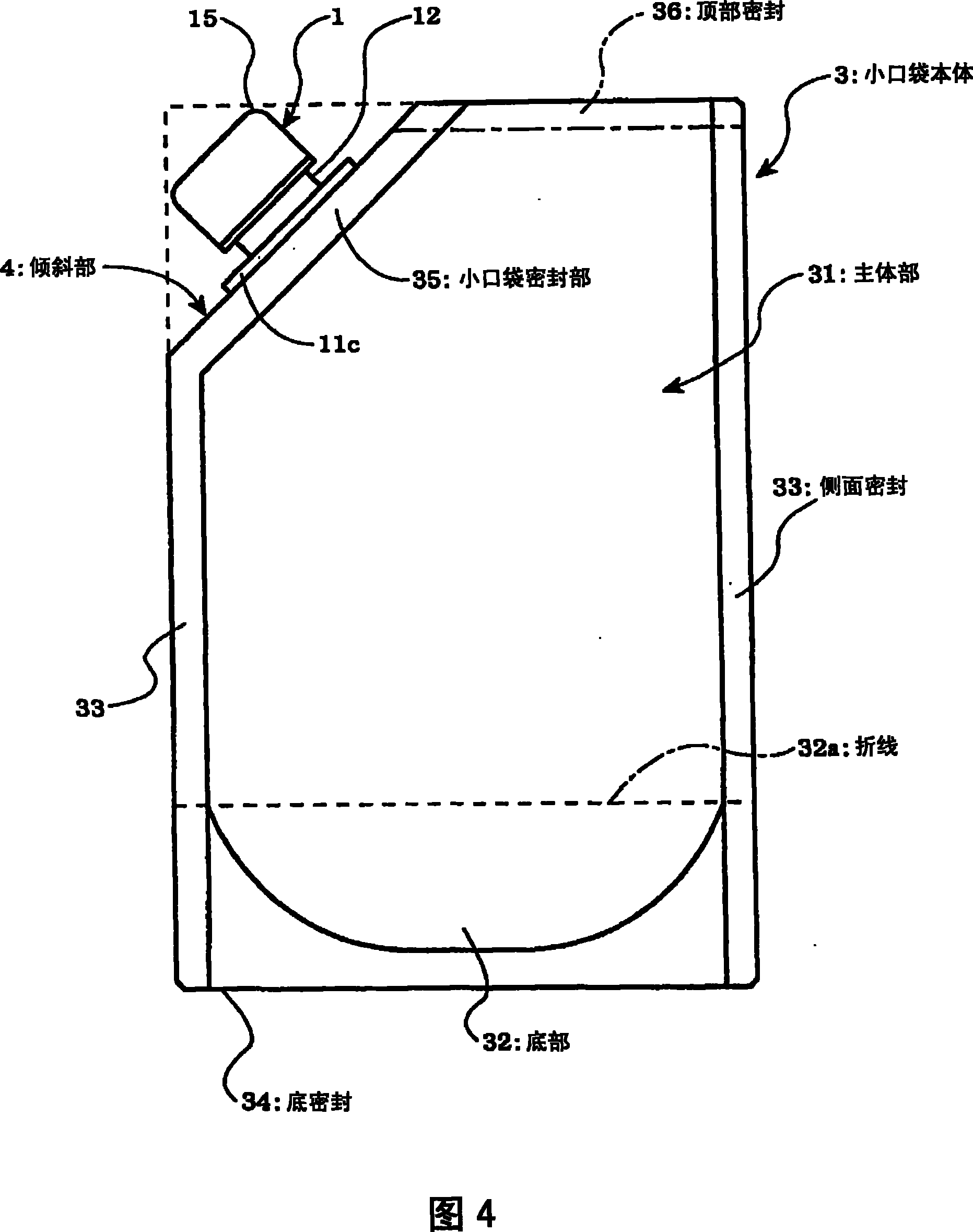

[0029] Here, FIG. 1 is a partially cutaway sectional view of the spout showing an embodiment in which the container sealing structure of the present invention is applied to the spout for a pouch. In addition, FIG. 2 is an enlarged cross-sectional view of a portion surrounded by chain lines in FIG. 1 .

[0030] The spout 1 shown in FIG. 1 has a spout body 10 including a boat portion 11 and a cylindrical pouring cylinder 12 extending upward from the boat portion 11 . A sealing member 13 is heat-sealed on the upper end surface of the opening of the pouring cylinder 12 . In addition, on the outer peripheral surface of the pouring cylinder 12, a thread 14 for screwing the cap 15 is formed, and a plurality of notches 14a for drainage are provided in the circumferential direction on the thread 14 .

[0031] Furthermore, the opening of the pouring cylinder 12 is sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com