Arrangement for the treatment of cellulose pulp in a washing apparatus arranged with a reinforcing frame

A technology of cellulose pulp and pulp washing, applied in the direction of washing/replacing pulp treatment liquid, etc., can solve the problems of cost increase, transportation difficulties, etc., and achieve the effect of reducing static weight, less materials, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

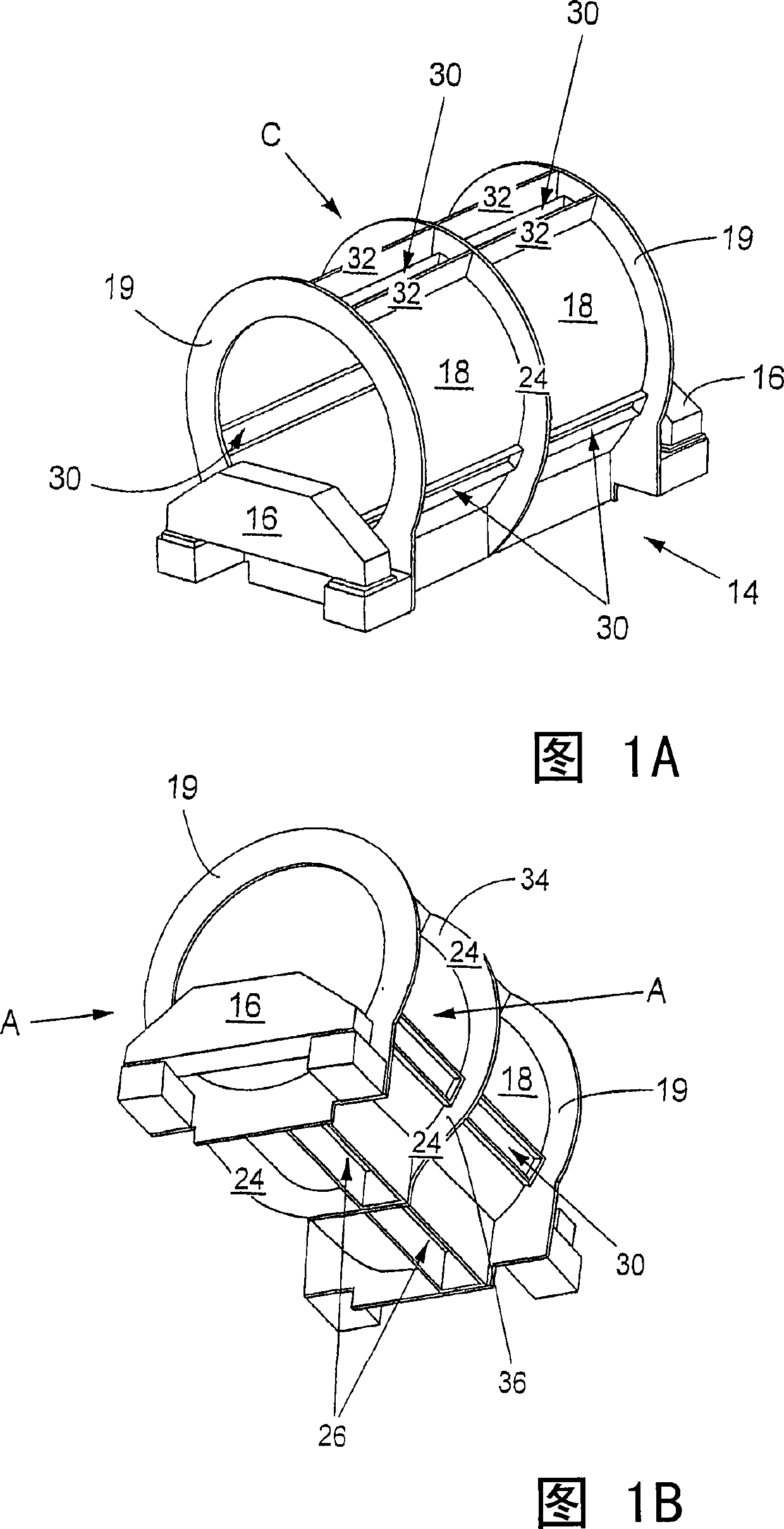

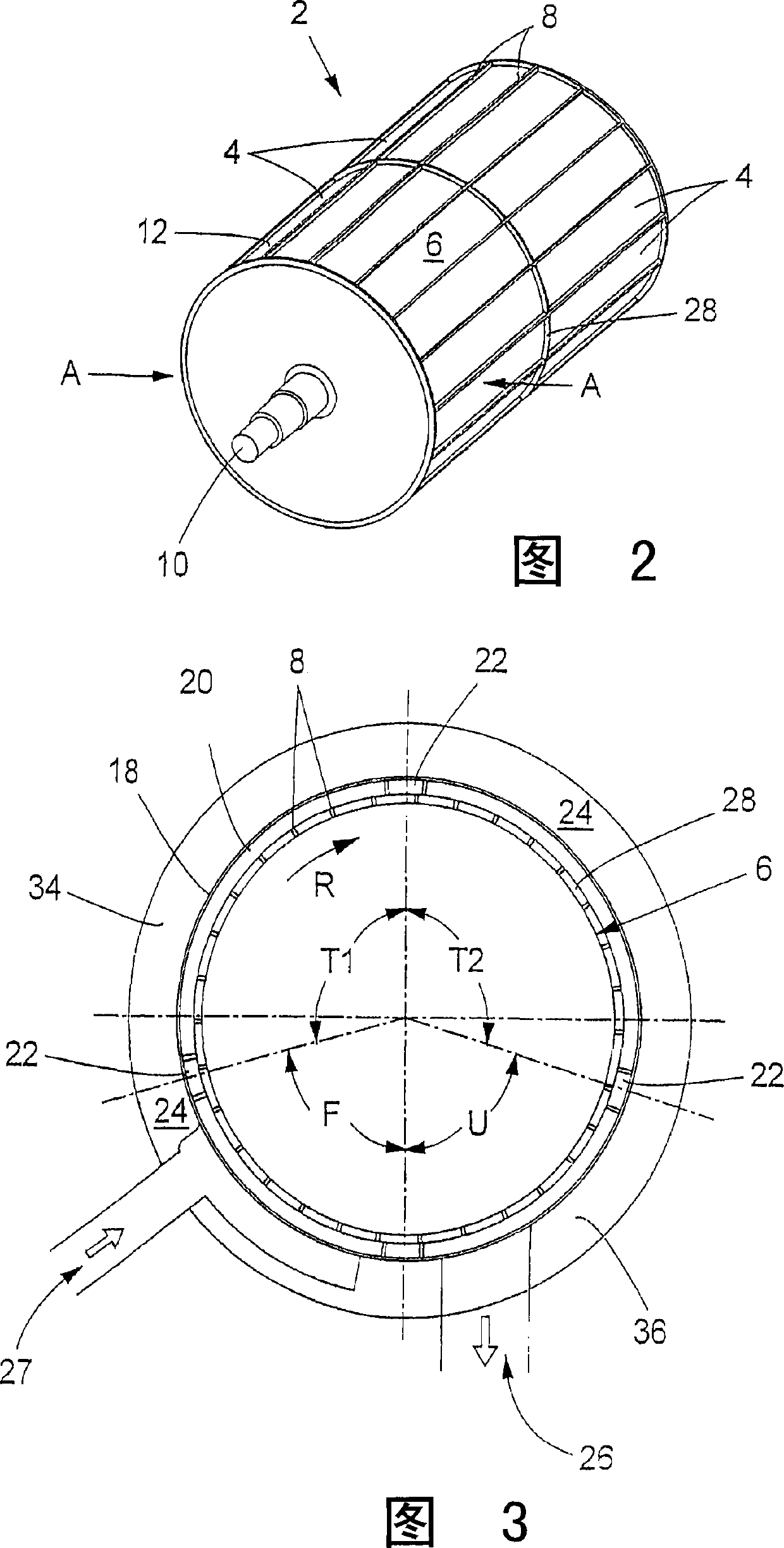

[0019] Figures 1A-B and Figure 2 show the main parts of a washing plant for washing cellulose pulp according to the pressure removal washer type. The washing unit comprises a rotatable drum 2 provided with a plurality of external compartments 4 with a bottom 6 made of perforated metal, the pulp to be washed is removed during an on-drum feed placed in these compartments. The compartments 4 are delimited by compartment walls 8 arranged axially along the entire axis 10 of the drum and distributed along the circumference 12 of the drum. The washing unit comprises a fixed support structure 14 with two opposing transverse beams 16 . The drum 2 extends between two transverse beams and is rotatably journalled on these two transverse beams 16 of the support structure. A fixed cylindrical casing 18 having two opposing gables 19 surrounds the drum 2 so as to define an annular space 20 between the casing 18 and the drum 2 (see FIG. 3 ).

[0020] Washing liquid is fed to the annular spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com