Powder dust adsorbing device

An adsorption device and technology for dust, which are applied in the fields of dispersed particle separation, chemical instruments and methods, dispersed particle filtration, etc., can solve the problems of high energy consumption of the power system, difficult maintenance and cleaning, poor chemical stability, etc., and achieve high purification efficiency and adsorption. The effect of large dust volume and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

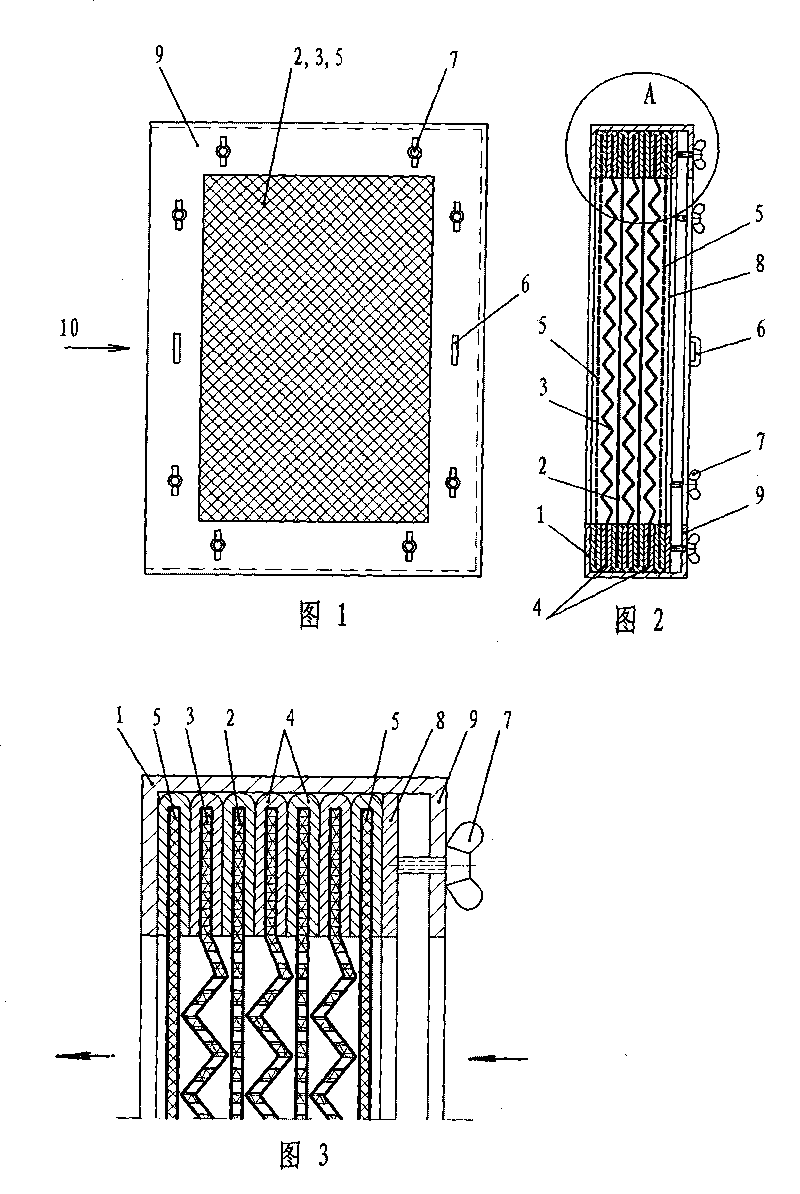

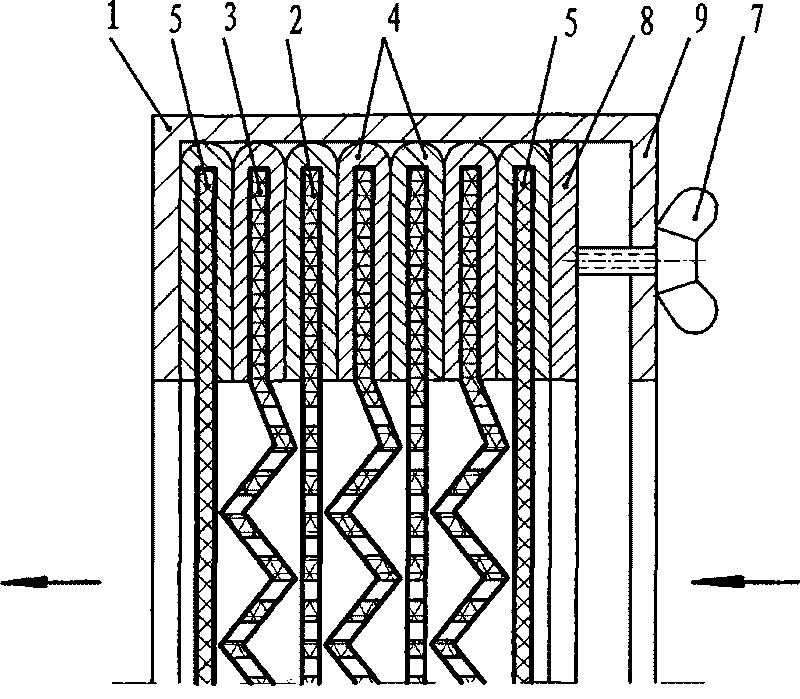

[0013] Depend on Figure 1 ~ Figure 3 It can be seen that the dust adsorption device of the present invention includes several layers of flat filter screens 2 or / and corrugated filter screens 3 made of stainless steel materials that are stacked in the frame and / or corrugated filter screens 3, and the flat filter screens 2 and corrugated filter screens The filter screens 3 are arranged and stacked sequentially from thick to fine. Wherein the frame is a hollow structure in which one side is provided with an opening 10, and the other side is connected with the upper and lower frame 9, 1; Stacking; a pressure frame 8 is provided between the upper frame 9 and the U-shaped connector 4, and the pressure frame 8 presses the U-shaped connector 4 made of elastic material through several adjusting screws 7 installed on the upper frame 9 . Reinforcing filter screens 5 are respectively provided on the outer layers of several layers of filter screens 2 and 3 . All flat filter screens 2, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com