Rotating filter cartridge dust remover with ashing suction nozzle

A technology of rotating filter cartridges and dust collectors, which is applied in the fields of dispersed particle filtration, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problem that the rotation speed cannot be adjusted to control the dust removal efficiency, the effective processing capacity of the dust collector is reduced, and the operation of the dust collector is affected. performance and other issues, to solve the problem of high temperature dust removal, reduce investment and operating costs, and achieve the effect of fewer components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

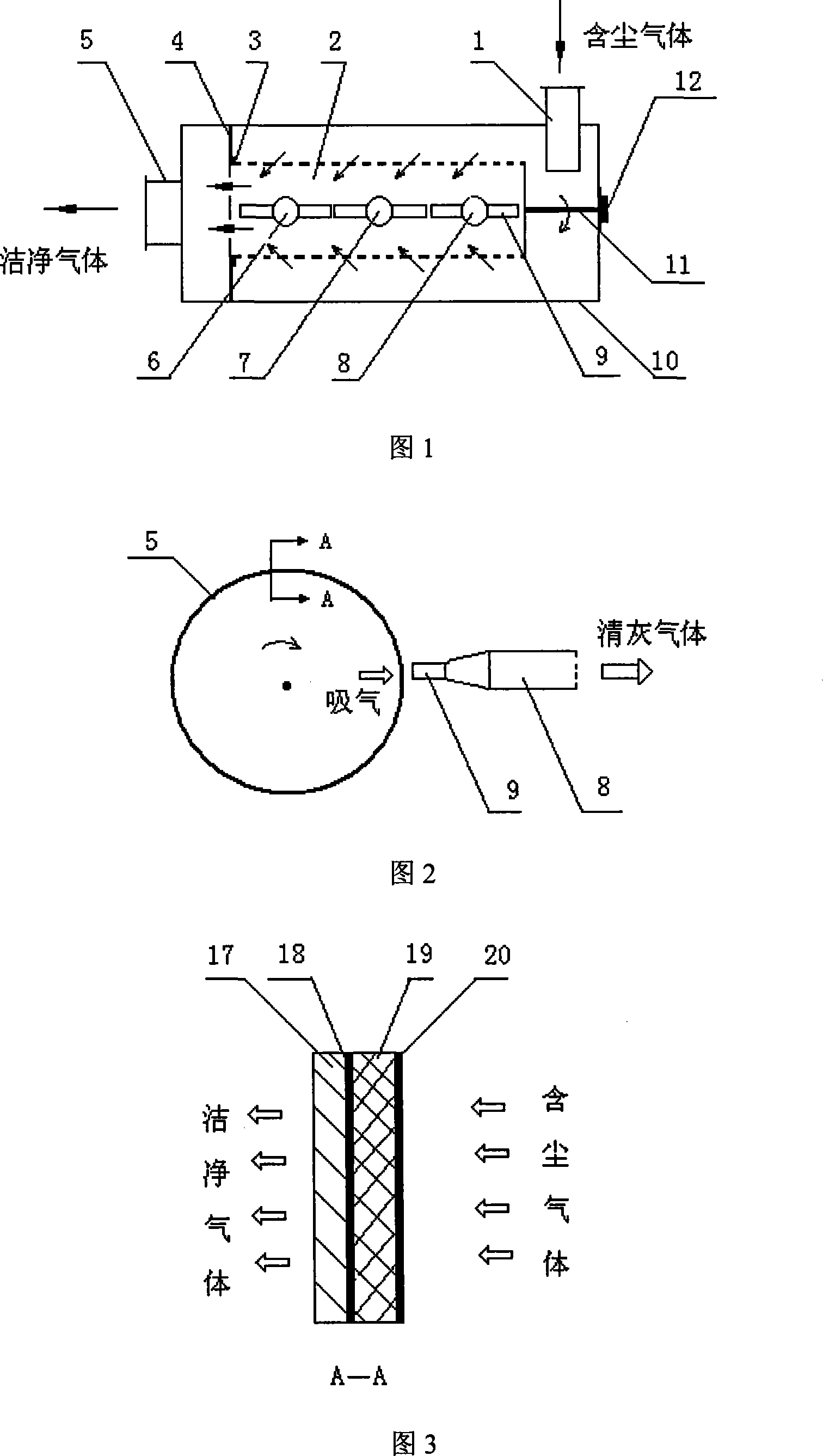

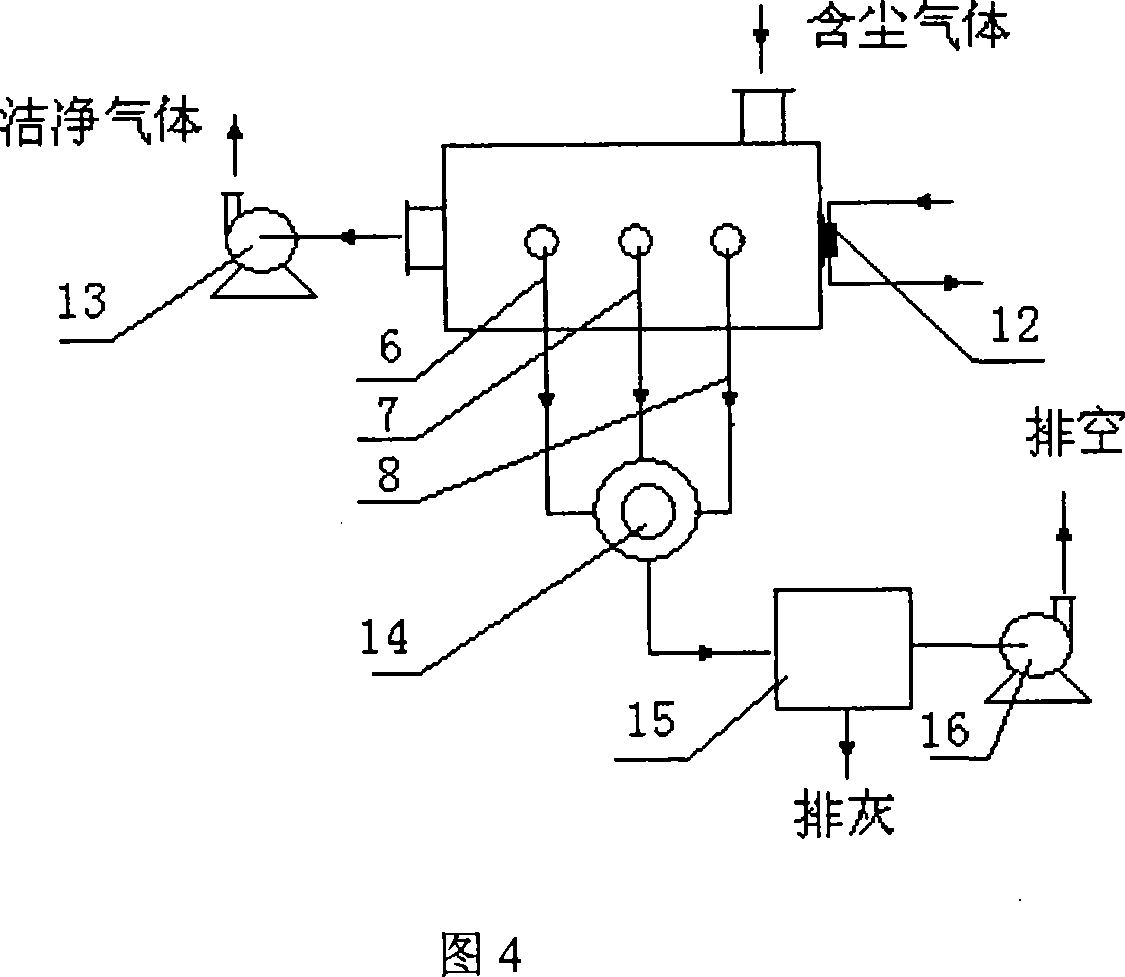

[0030] The implementation of the present invention is shown in Figure 1, which includes a dust-laden gas inlet distributor 1. After the dust-laden gas enters the dust collector, it is filtered inwardly on the outer surface of the rotating filter cartridge 2 due to the action of fan suction or blast. The clean gas enters the purified gas outlet 5 through the middle passage of the partition 4, the rotary filter cartridge 2 and the partition 4 are sealed by the seal 3, and the pneumatic rotating device 12 drives the filter cartridge to rotate through the rotating shaft 11.

[0031] As shown in Figure 2, the dust removal nozzle 9 is fixed, the filter cartridge rotates, the dust on the surface of the filter cartridge is sucked away by the dust removal nozzle 9, and the dust removal gas is sent to the external dust removal gas purification device 15 by the suction pipe 8 deal with.

[0032] As shown in FIG. 3 , the filter layer of the filter cartridge is composed of four parts: a su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com