Technique method using metal sheet material to draft connecting component like buckles

A metal sheet and process technology, applied in the direction of fasteners, buttons, buttons, etc., can solve the problems of waste of raw materials, narrowing of the width of the material belt, button bursting, etc., to reduce labor costs, reduce supply, reduce effect of width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

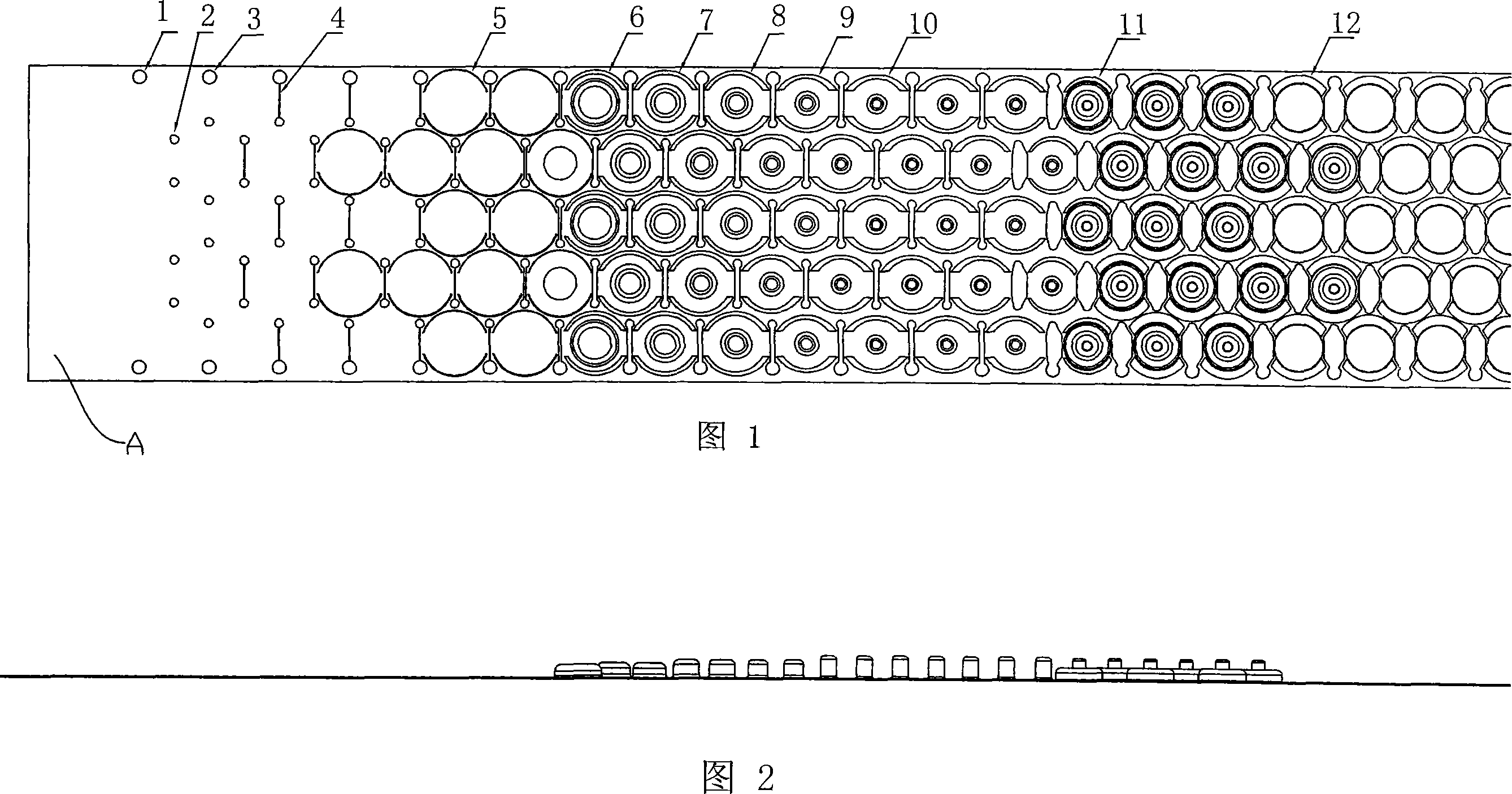

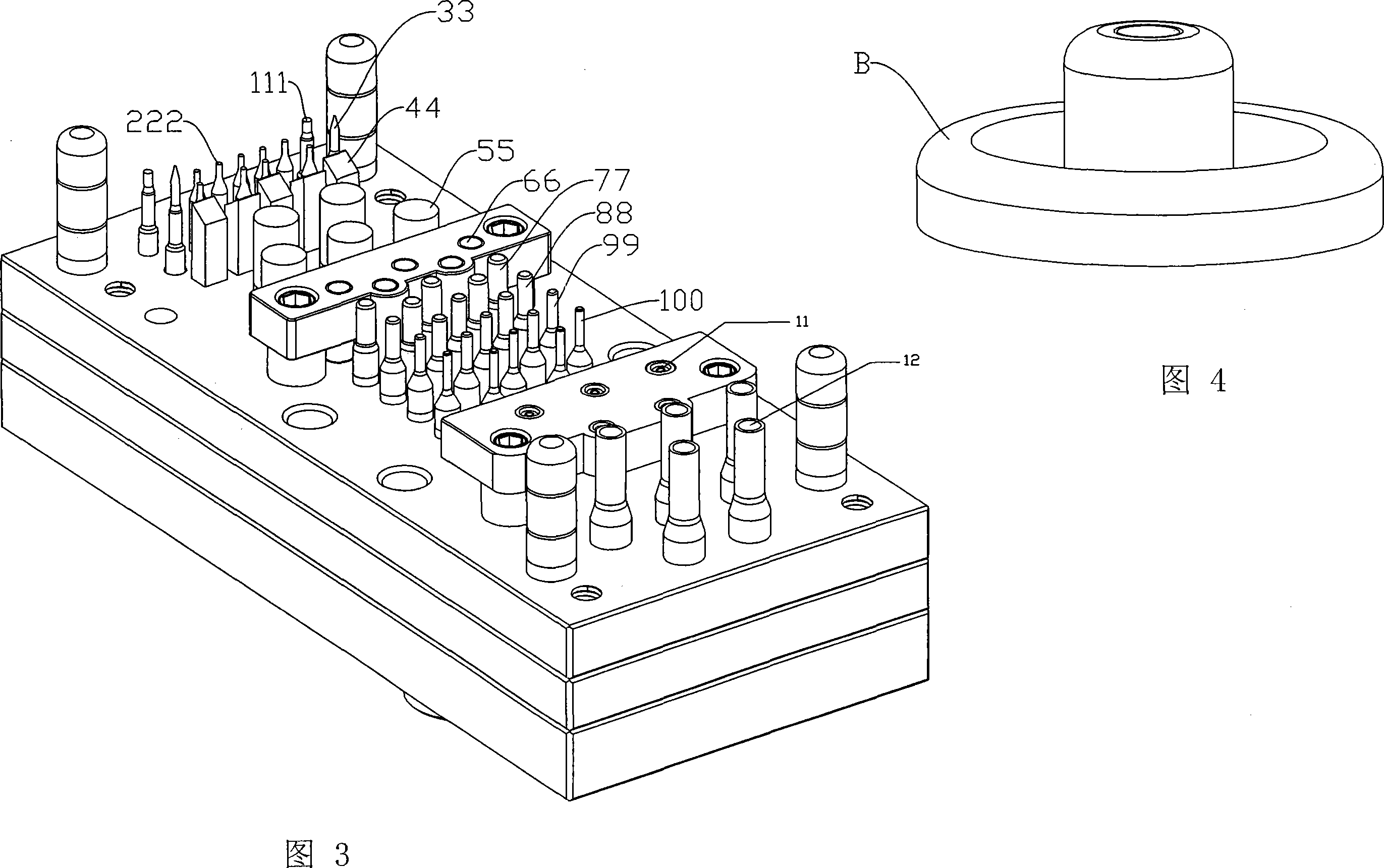

[0045] Embodiment 1, as shown in Fig. 1, Fig. 2, Fig. 3, Fig. 4:

[0046] In this embodiment, what needs to be stretched is a metal button connector called button bead B, as shown in Figure 4, which includes the following process steps:

[0047] A. Positioning hole on stamping edge:

[0048] In this embodiment, the width of one beer and five outs is used to select the metal sheet. First, according to the size of the buckle connector to be stretched, use the punching pins 111, 33 on the mold to punch out the edge positioning holes 1, 33 on both sides of the metal sheet. 3. The positioning hole of the fork needle in this step is used to fix the material belt stroke, ensure the accuracy of material belt feeding, ensure the stability of product quality and the service life of the production mold, and can also prevent the hole from being stretched and grab the material. Process protection The width of the material tape will not shrink during stretching, ensuring that the distance...

Embodiment 2

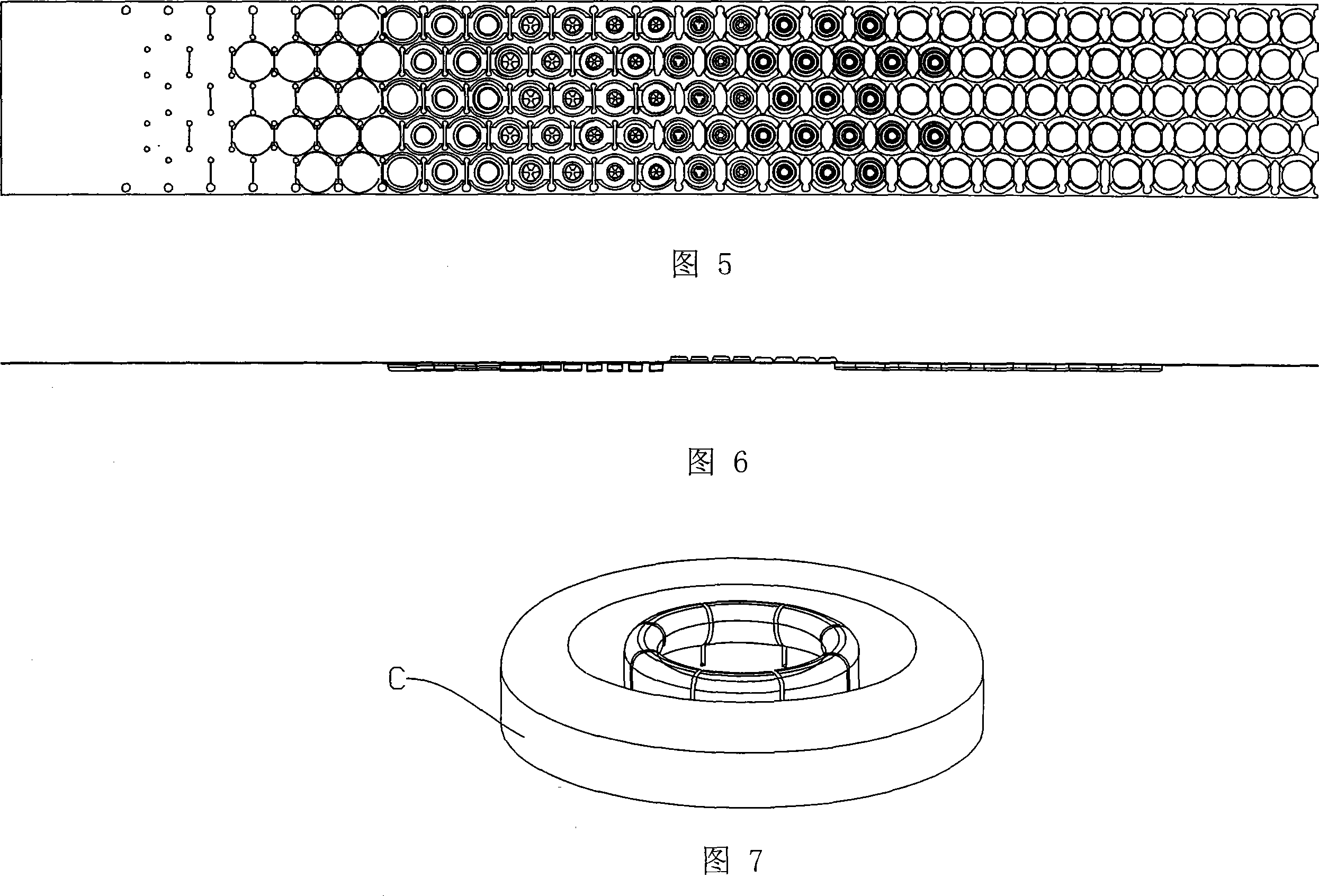

[0061] Embodiment 2, as shown in Fig. 5, Fig. 6, Fig. 7:

[0062]In this embodiment, the stretched buckle connector is meson C, and what is used is also a metal sheet with five outs. In the embodiment, the punching edge positioning hole, the punching fastener positioning hole, the center cutting knife, The splitting of the trimmings, the forming of the cups and the blanking of the trimmings are the same as those in Example 1. The difference is the step-by-step stretching process. In this embodiment, according to the final forming requirements of the meson, firstly, it will go through ordinary stretching of the edge plate and three rows of stamping columns, and then divide it into eight equal parts with a chopping knife. , and then carry out three separate stretches, and through the reverse position, punching, reverse eight-petal forming, eight-petal forming and then enter the drawing cup forming process to form the finished product of the meson. The reverse position, punching...

Embodiment 3

[0063] Embodiment 3, as shown in Fig. 8, Fig. 9, Fig. 10:

[0064] The buckle connectors stretched in this embodiment are corns D, and the metal plates with one beer and five outs are also used as raw materials. Processes such as material, flash conjoined notch splitting, cup drawing molding and notch blanking are the same as in embodiment 1.

[0065] The difference in this embodiment is that five-stage stretching is used, and after step-by-step stretching, punching is performed again, and then R-stretching is used to form the final corn product. Step-by-step stretching and punching as well as the R-stretch forming technology can all adopt the process methods in the prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com