Aluminum alloy electromagnetic field auxiliary casting crystallizer

A casting crystallizer and electromagnetic field technology, which is applied in the field of aluminum alloy electromagnetic field assisted semi-continuous casting crystallizers, can solve the problems of easy leaking and difficult casting forming, and achieve the requirements of reducing friction, reducing control accuracy, and improving penetration ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

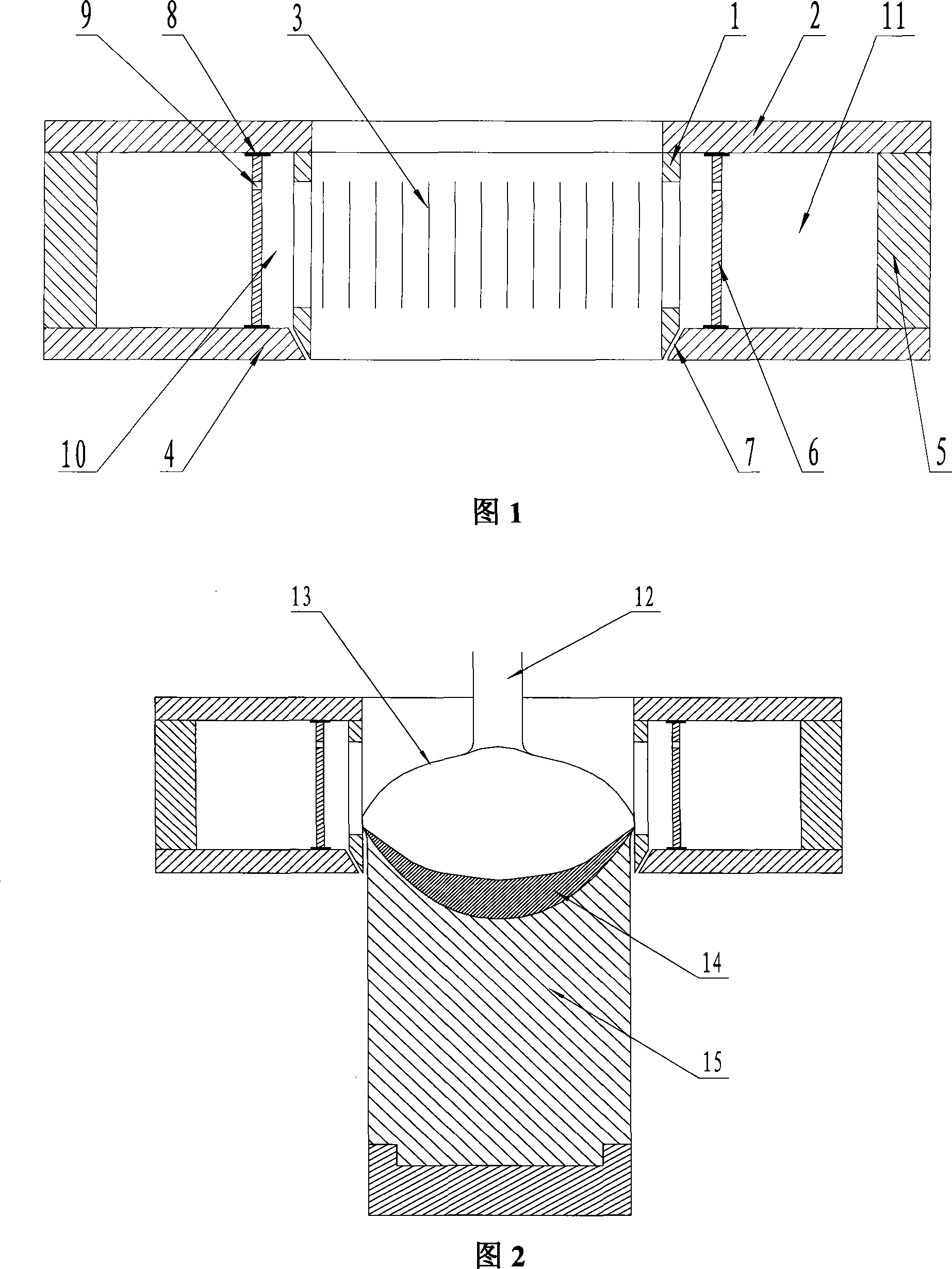

[0020] The aluminum alloy electromagnetic field assisted casting crystallizer of the present invention, the electromagnetic induction coil is arranged in the crystallizer to generate the auxiliary electromagnetic field, and the electromagnetic constraint force and the crystallizer wall are used to constrain the molding, so as to reduce the harsh operation requirements of electromagnetic casting, and at the same time improve the surface of the aluminum alloy ingot quality.

[0021] As shown in Figure 1, an aluminum alloy electromagnetic field assisted casting mold includes an upper wall 2, a lower wall 4, an outer wall 5 and an inner wall 1, forming a frame structure. The inner wall 1 of the crystallizer is made of forged aluminum, and the thickness of the inner wall 1 is 5 ~ 15mm, and the inner wall is provided with slits. The upper wall, lower wall and outer wall of the crystallizer are not cut, but the thickness is inconsistent. The thickness of the upper wall and the lower ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com