Long sleeves adhesive tape and vehicle-carrying wire harness using the same

A tape and long-sleeved technology, applied in the field of vehicle wiring harness, can solve the problems of waste of materials, waste of man-hours and interference of front cabin wiring harness, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

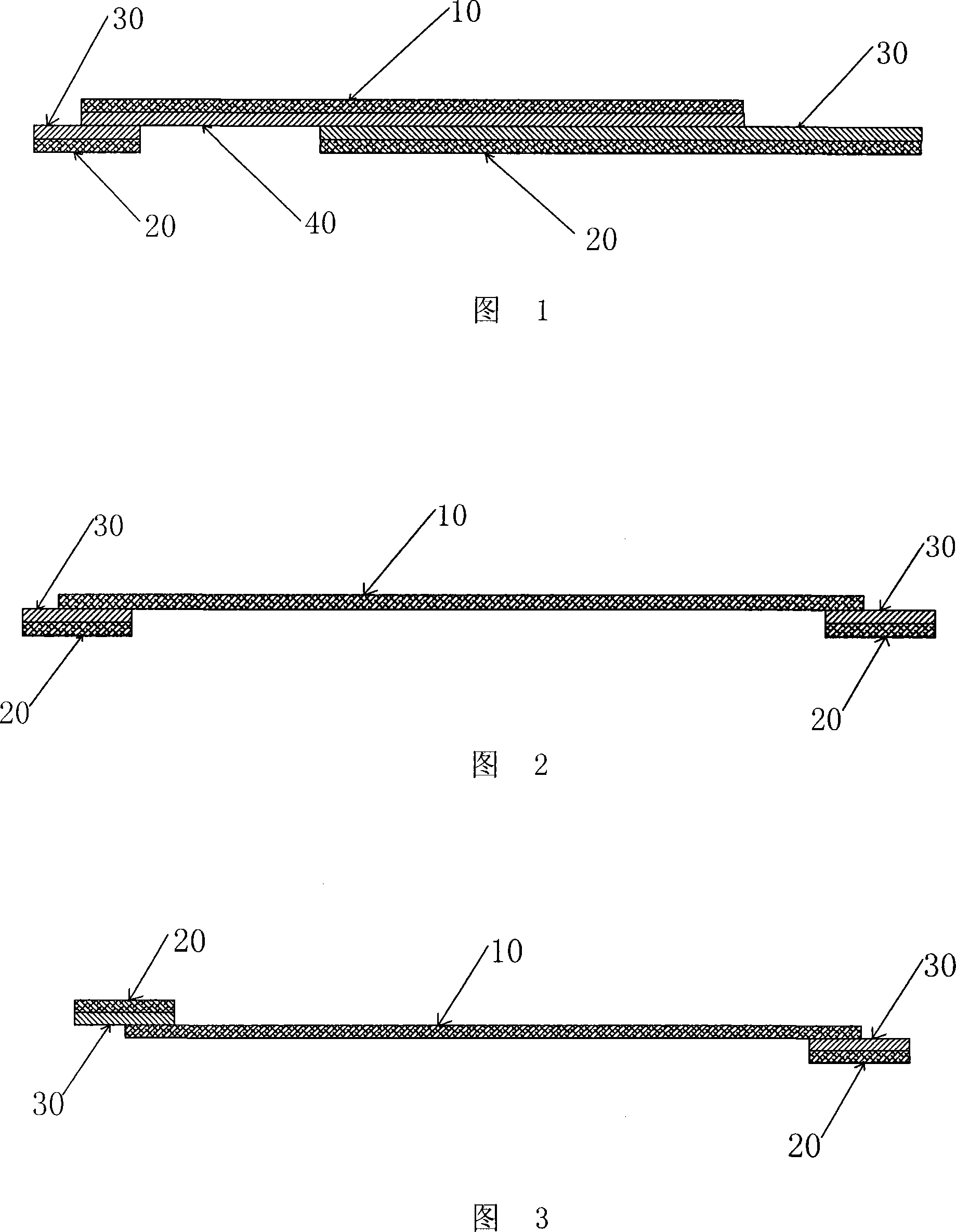

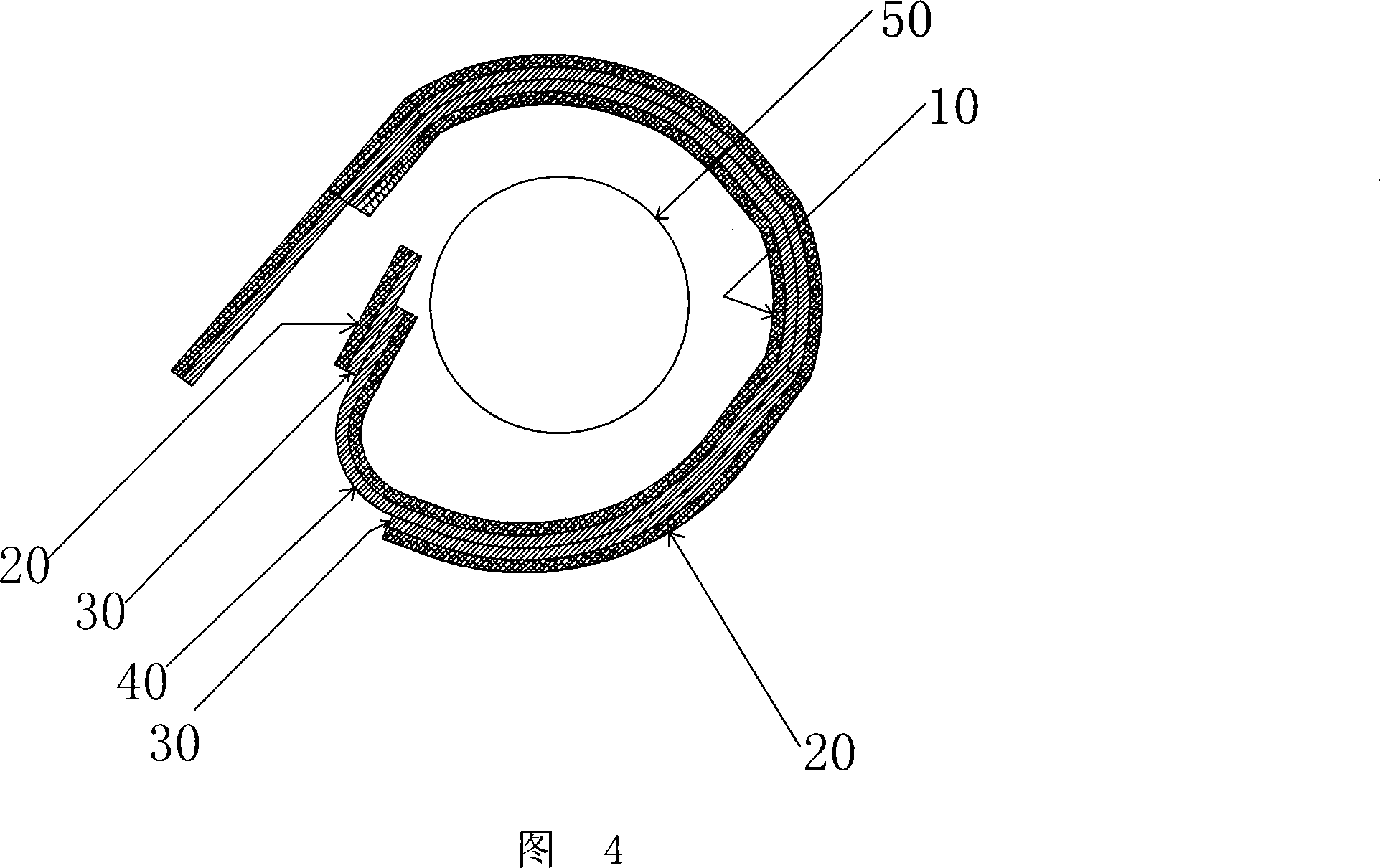

[0013] Embodiment two is the long-sleeved adhesive tape for the common type front cabin, as shown in Figure 2, the belt edge of the same plane of the main base material 10 is provided with strip-shaped auxiliary base material 20 along the belt length direction, on the auxiliary base material 20 Covered with a strip-shaped adhesive layer 30, a part of the adhesive layer 30 on the auxiliary substrate is bonded to the main substrate 10, and the other part is exposed. These two types of long-sleeved tapes for the front cabin use the same base material and glue material, and the thickness of the main base material 10 and auxiliary base material 20 of the wear-resistant long-sleeved tape is relatively large, which is suitable for occasions where there is interference or dynamics. During bandaging, the glued layer 30 on one end of the long-sleeved adhesive tape is bonded to the vehicle wiring harness, and the glued layer 30 on the other end is bonded to the main substrate 10 .

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com