High-intensity high-tenacity super fine crystal WC-10Co hard alloy preparation method

A cemented carbide and high toughness technology, which is applied in the field of preparing high-strength and high-toughness ultra-fine-grained WC-Co cemented carbide materials to achieve high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

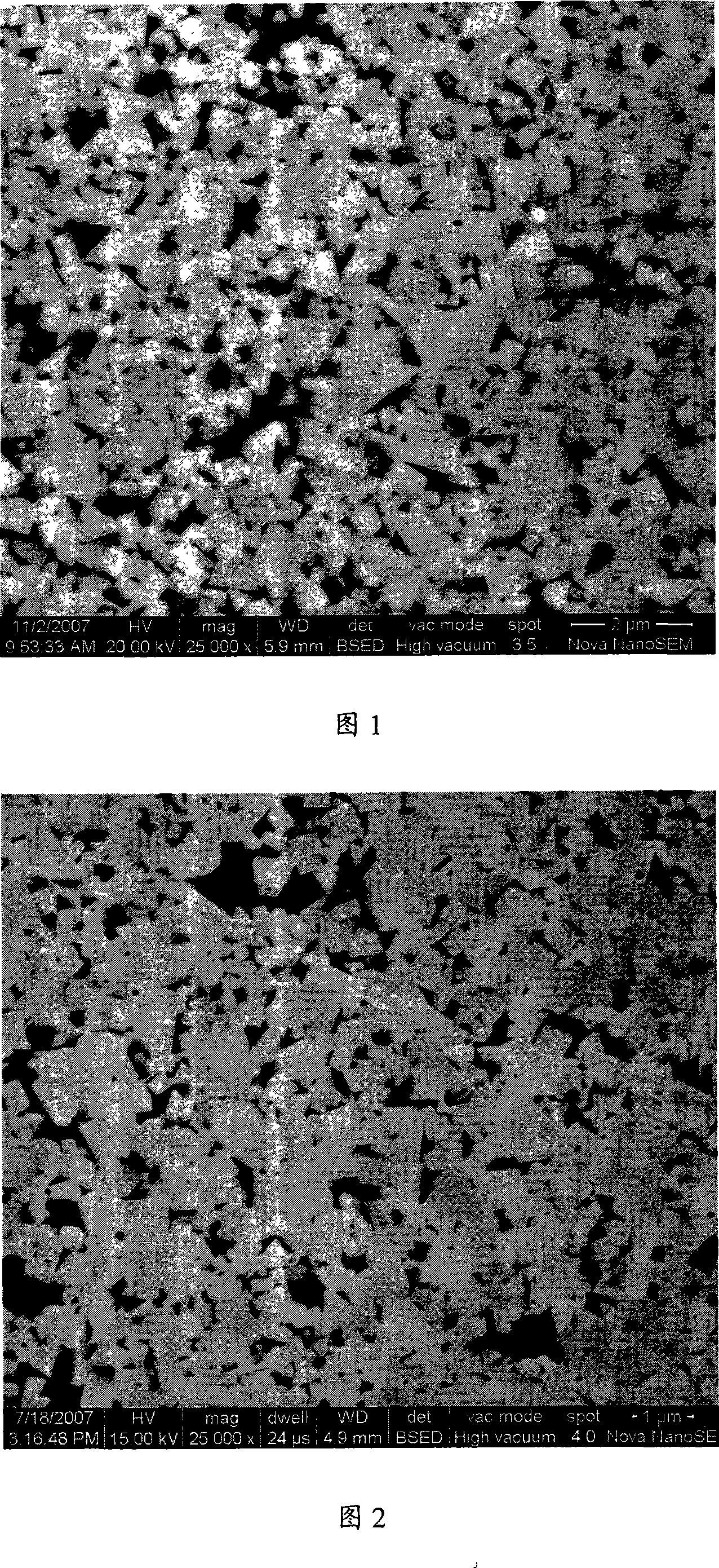

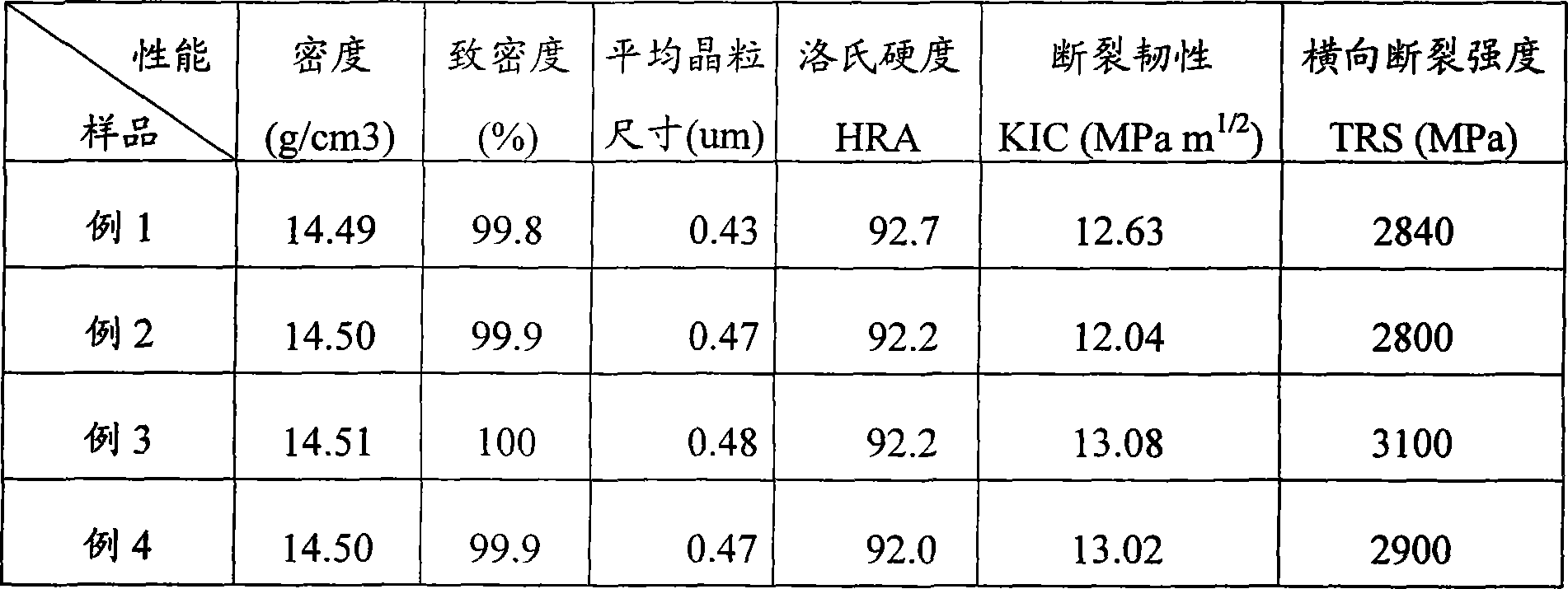

[0014] Example 1: First, 0.5 micron WC powder and 0.5 micron Co powder were mixed and ball milled, the ball-to-material ratio was 3:1, the ball milling speed was 150 r / min, the ball milling time was 24 hours, and the ball milling medium was absolute ethanol. The mixed powder after ball milling is dried and put into graphite mold, pressurized and put into vacuum furnace for vacuum pretreatment. The pretreatment temperature is 1300°C, and the holding time is 1 hour. After vacuum pretreatment, it is sent to the sintering chamber of the SPS system. The sintering process parameters are as follows: sintering temperature 1180°C; sintering heating rate 50°C / min; sintering pressure 80MPa; heat preservation for 10min after reaching the sintering temperature. The ultrafine-grained YG10 cemented carbide bulk material was prepared by the above process (see Figure 1 for the microstructure and Table 1 for the material performance parameters).

Embodiment 2

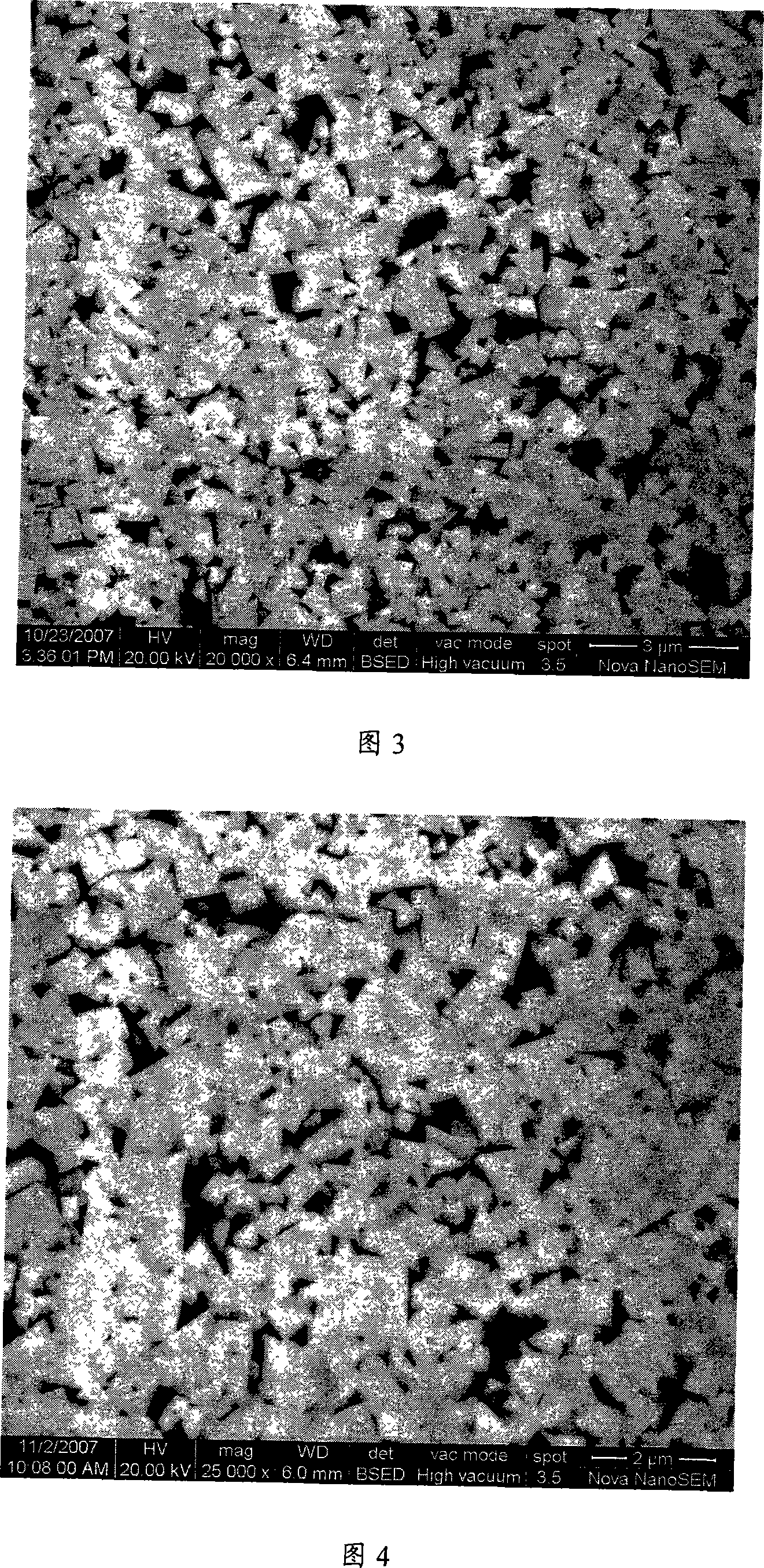

[0015] Example 2: First, 0.8 micron WC powder and 0.8 micron Co powder were mixed and ball milled, the ball-to-material ratio was 1:1, the ball milling speed was 250 r / min, the ball milling time was 24 hours, and the ball milling medium was absolute ethanol. The mixed powder after ball milling is dried and put into graphite mold, pressurized and put into vacuum furnace for vacuum pretreatment. The pretreatment temperature is 1200°C, and the holding time is 1 hour. After vacuum pretreatment, it is sent to the sintering chamber of the SPS system. The sintering process parameters are: sintering temperature 1200°C; sintering heating rate 100°C / min; sintering pressure 60MPa; heat preservation for 10min after reaching the sintering temperature. The ultra-fine-grained YG10 cemented carbide bulk material was prepared by the above process (see Figure 2 for the microstructure and Table 1 for the material performance parameters).

Embodiment 3

[0016] Example 3: First, 1.0 micron WC powder and 1.0 micron Co powder were mixed and ball milled, the ball-to-material ratio was 1:1, the ball milling speed was 250 r / min, the ball milling time was 24 hours, and the ball milling medium was absolute ethanol. The mixed powder after ball milling is dried and put into graphite mold, pressurized and put into vacuum furnace for vacuum pretreatment. The pretreatment temperature is 1300°C, and the holding time is 1 hour. After vacuum pretreatment, it is sent to the sintering chamber of the SPS system. The sintering process parameters are: sintering temperature 1180°C; sintering heating rate 80°C / min; sintering pressure 60MPa; heat preservation for 10min after reaching the sintering temperature. The ultra-fine-grained YG10 cemented carbide bulk material was prepared by the above process (see Figure 3 for the microstructure and Table 1 for the material performance parameters).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com