Composite spinneret pack for preparing flap optical fiber

A technology of composite spinneret components and optical fibers, which is applied in the direction of optical components, light guides, optics, etc., and can solve problems such as inability to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

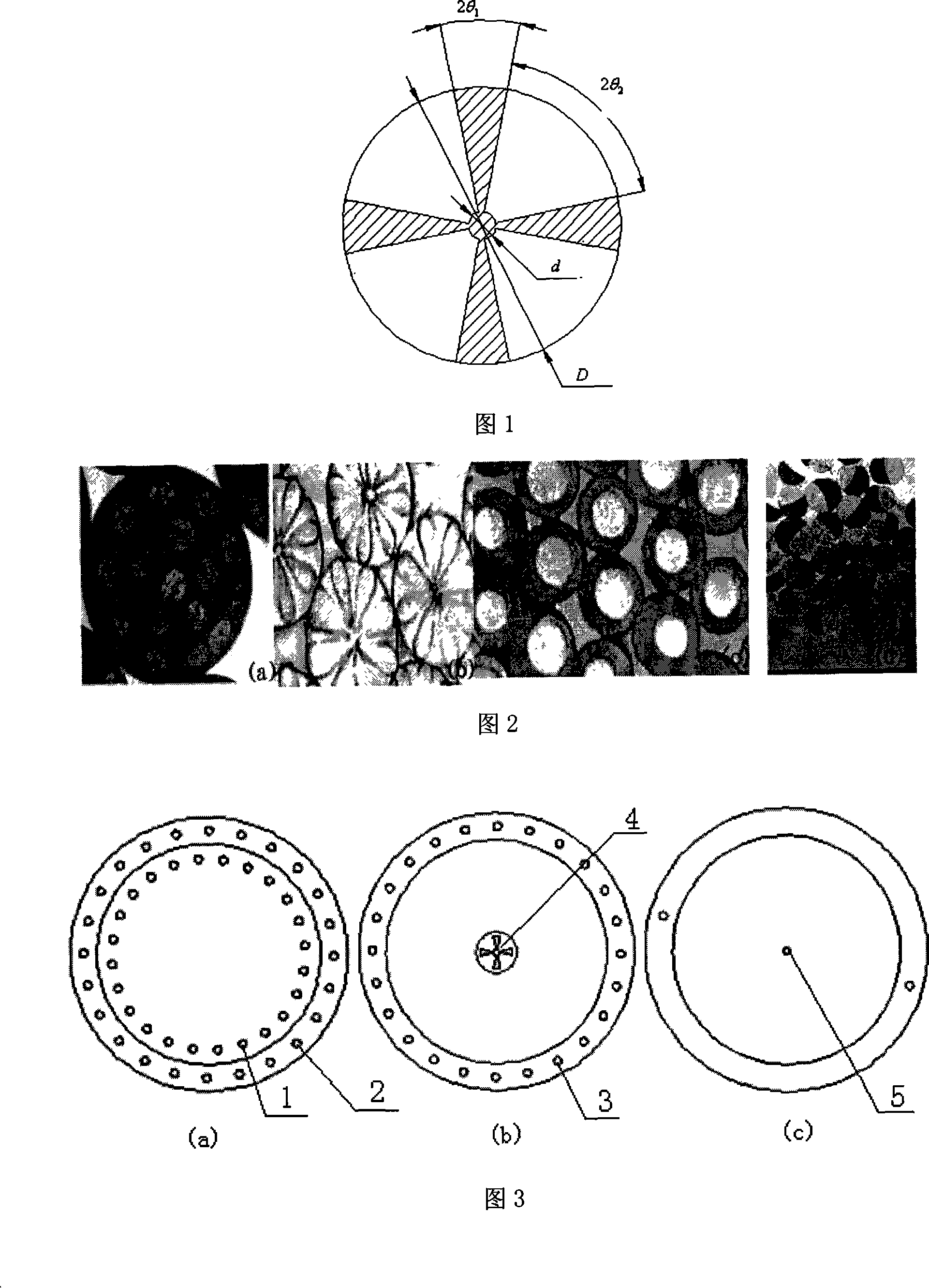

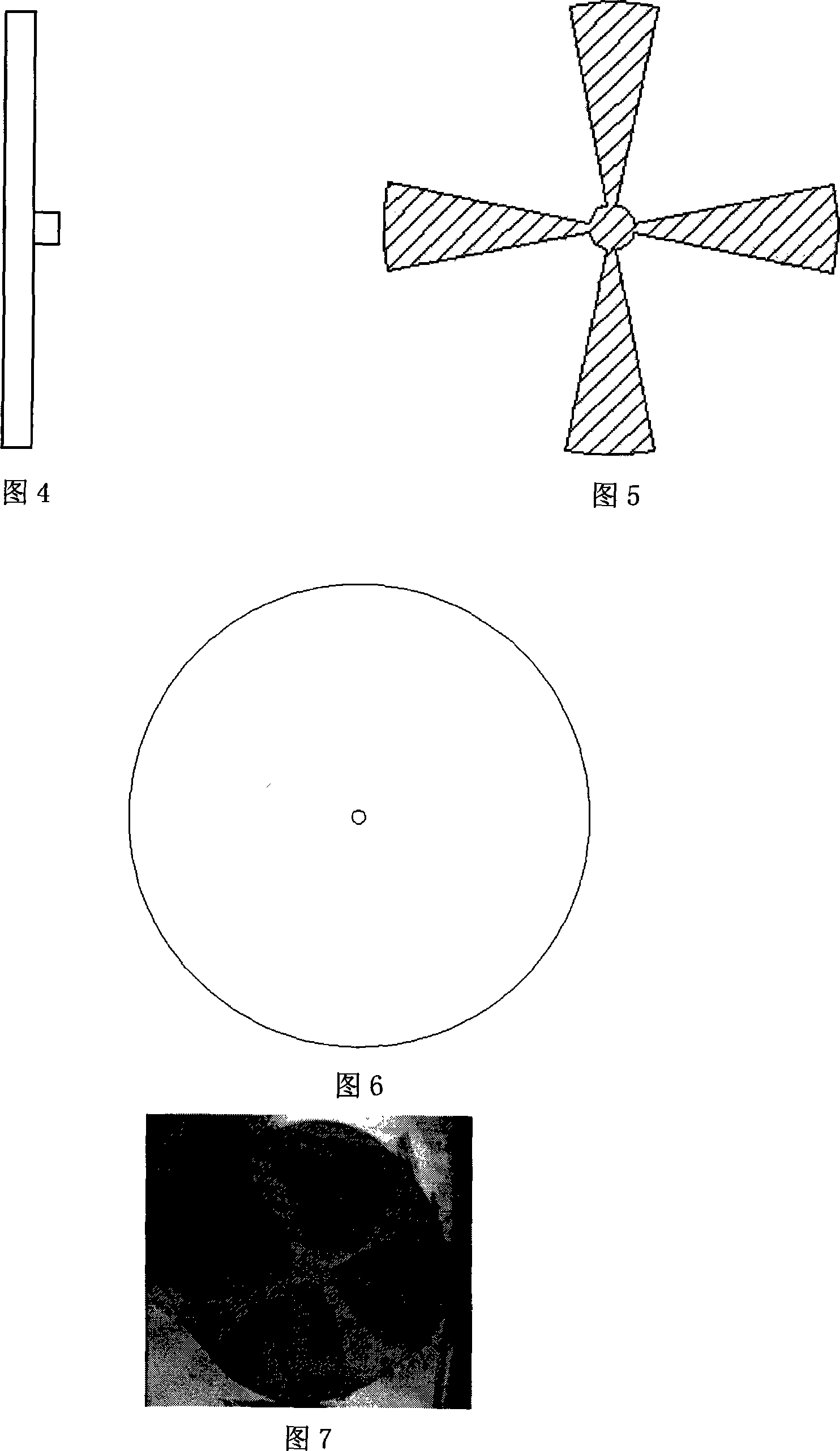

[0029] As shown in Figure 3, a composite spinneret assembly for preparing petal-shaped optical fibers includes a distribution plate A, a distribution B and a spinneret plate, and the A component channel 1 and the outer ring of the distribution plate A are provided on the inner ring There is a component B channel 2 on the top, the center of the distribution plate B is provided with a component A shaping hole 3 and the outer ring is provided with a component B channel 4, and the center of the spinneret is provided with a guide hole 5. The guide hole 5 is facing the A component shaping hole 3 in the center of the distribution plate B, and the bottom end of the guide hole is provided with a spinneret microhole, and the B component channel 4 is facing the B component channel 2 There are 24 described A component channels 1, B component channels 2 and B component channels 4, which are arranged in a circular array on distribution plates A and B; the length of the shaping hole 3 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com