Internal-combustion engine with decompressor

A technology for decompression devices and internal combustion engines, which is applied to valve devices, mechanical equipment, engine components, etc., to achieve the effect of improving switching accuracy and suppressing vibration, rotation and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

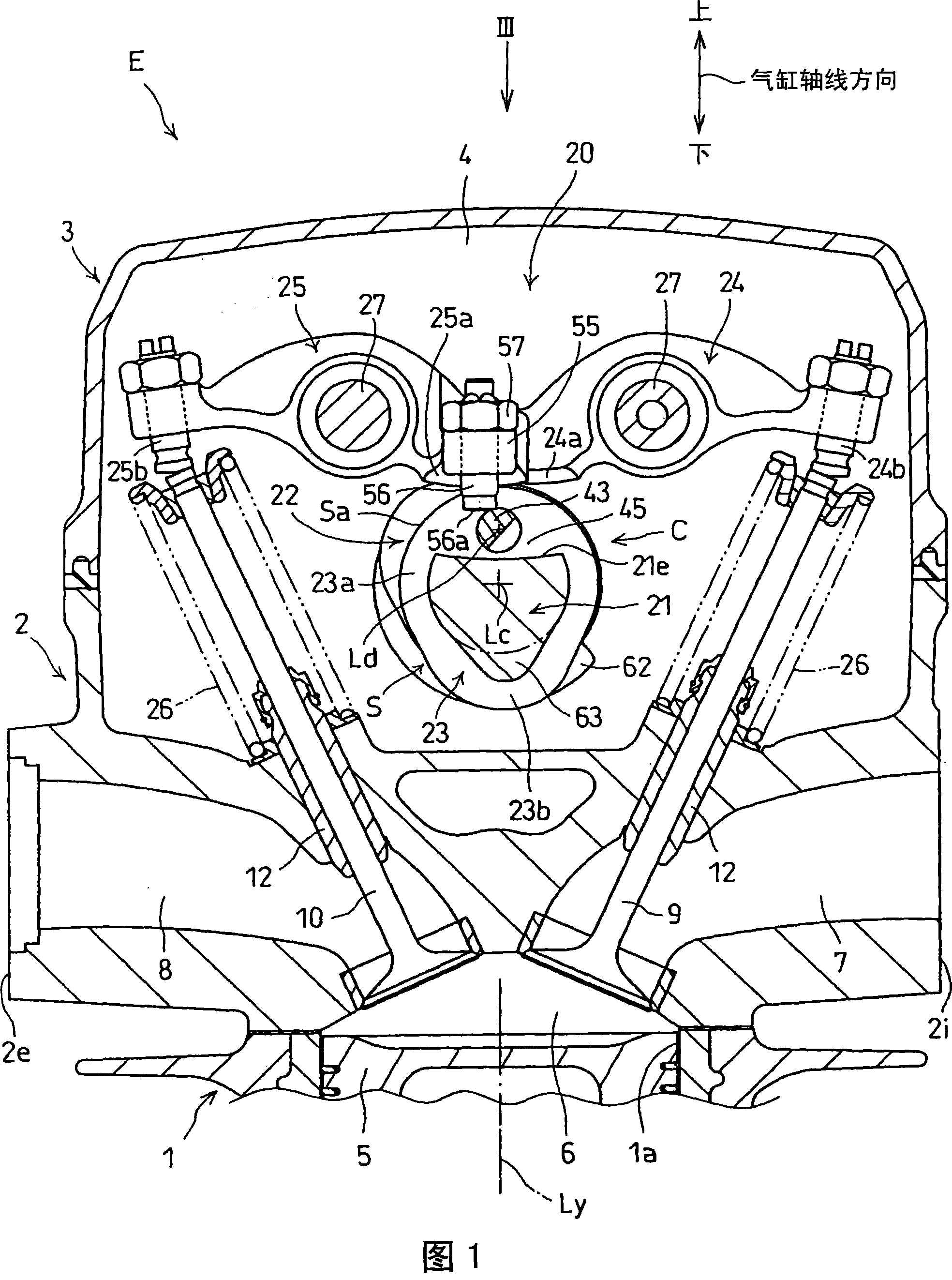

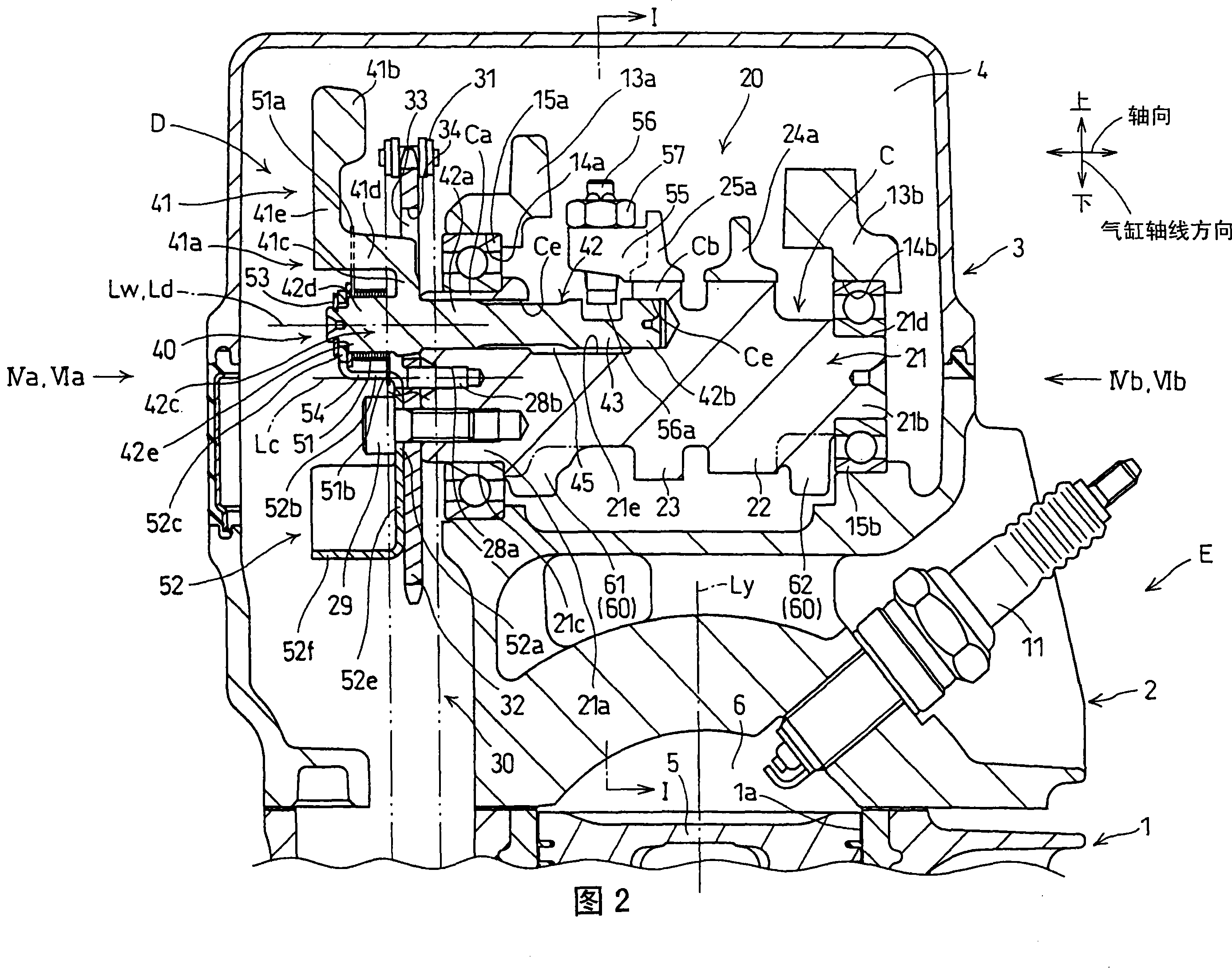

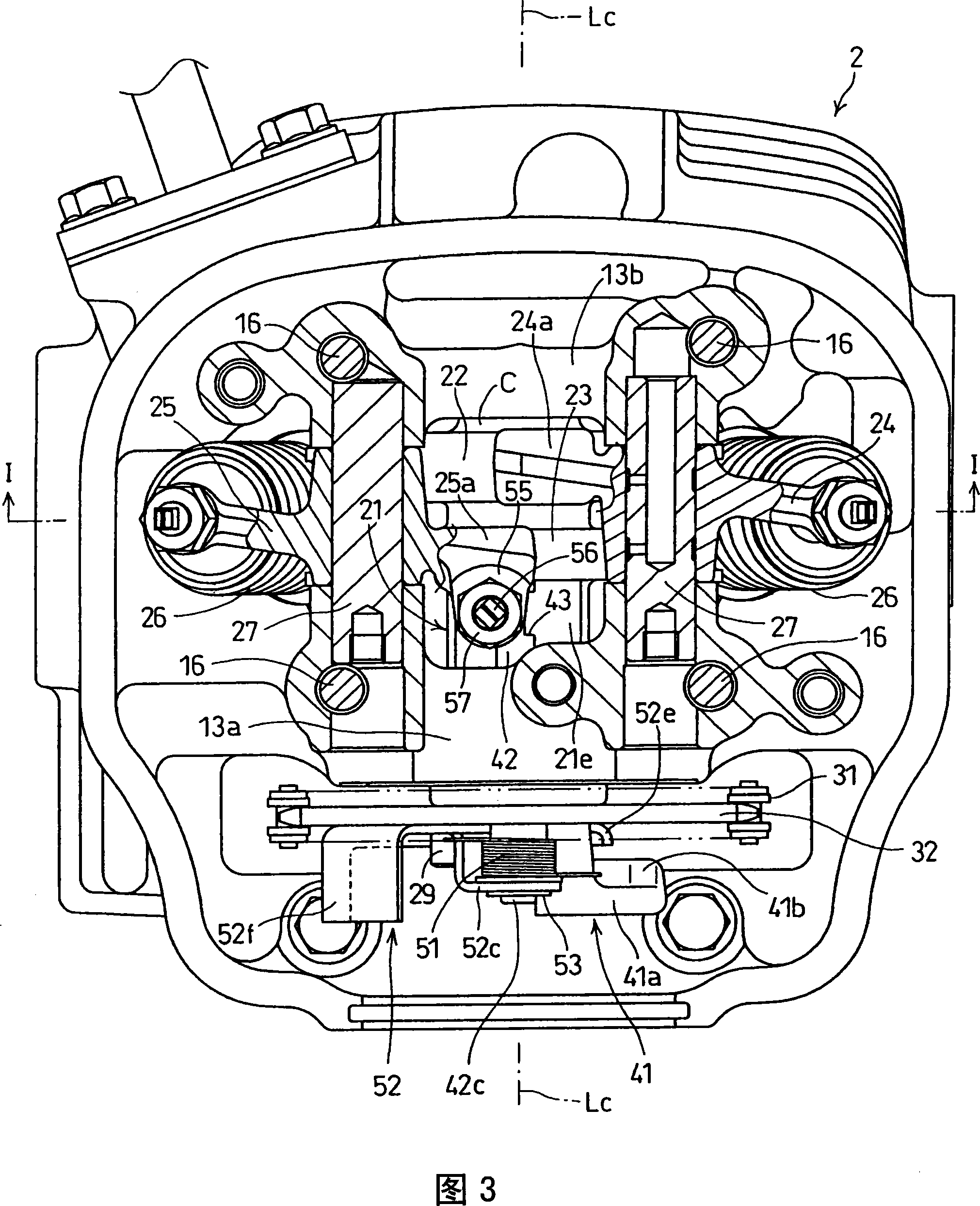

[0046] Next, an embodiment of the present invention will be described with reference to FIGS. 1 to 6 .

[0047] 1 and 2, the internal combustion engine E to which the present invention is applied is a single cylinder reciprocating 4-stroke internal combustion engine mounted on a motorcycle as a vehicle. The air-cooled internal combustion engine E is equipped with an engine main body composed of a cylinder 1 forming a cylinder bore 1a in which a piston 5 can reciprocate and fit, a cylinder head 2 connected to the upper end of the cylinder 1, and a cylinder head 2 connected to the upper end of the cylinder head 2. The cylinder head cover 3 is connected to the lower end of the cylinder 1 and includes a crankcase (not shown) that rotatably supports a crankshaft (hereinafter referred to as "crankshaft"). A valve chamber 4 is formed by the cylinder head 2 and the cylinder head cover 3 , and the valve chamber accommodates an overhead cam type valve device 20 mounted on the internal c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com