Method of producing optical element, and optical element

A technology of optical components and manufacturing methods, applied in the direction of optical components, optical components, optics, etc., can solve problems such as imperfection and light loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Embodiments of the present invention will be described with reference to the drawings.

[0063] [Embodiment 1]

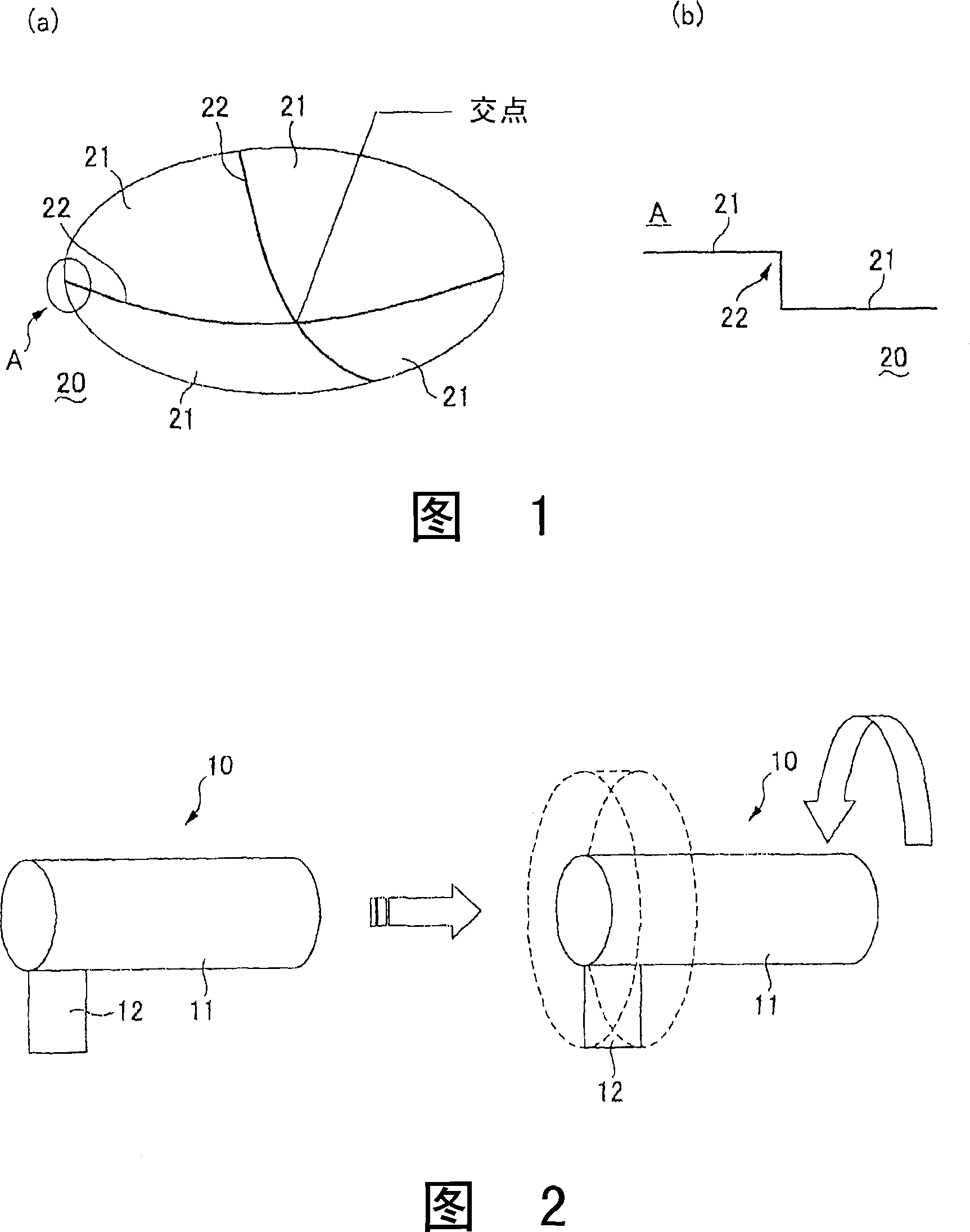

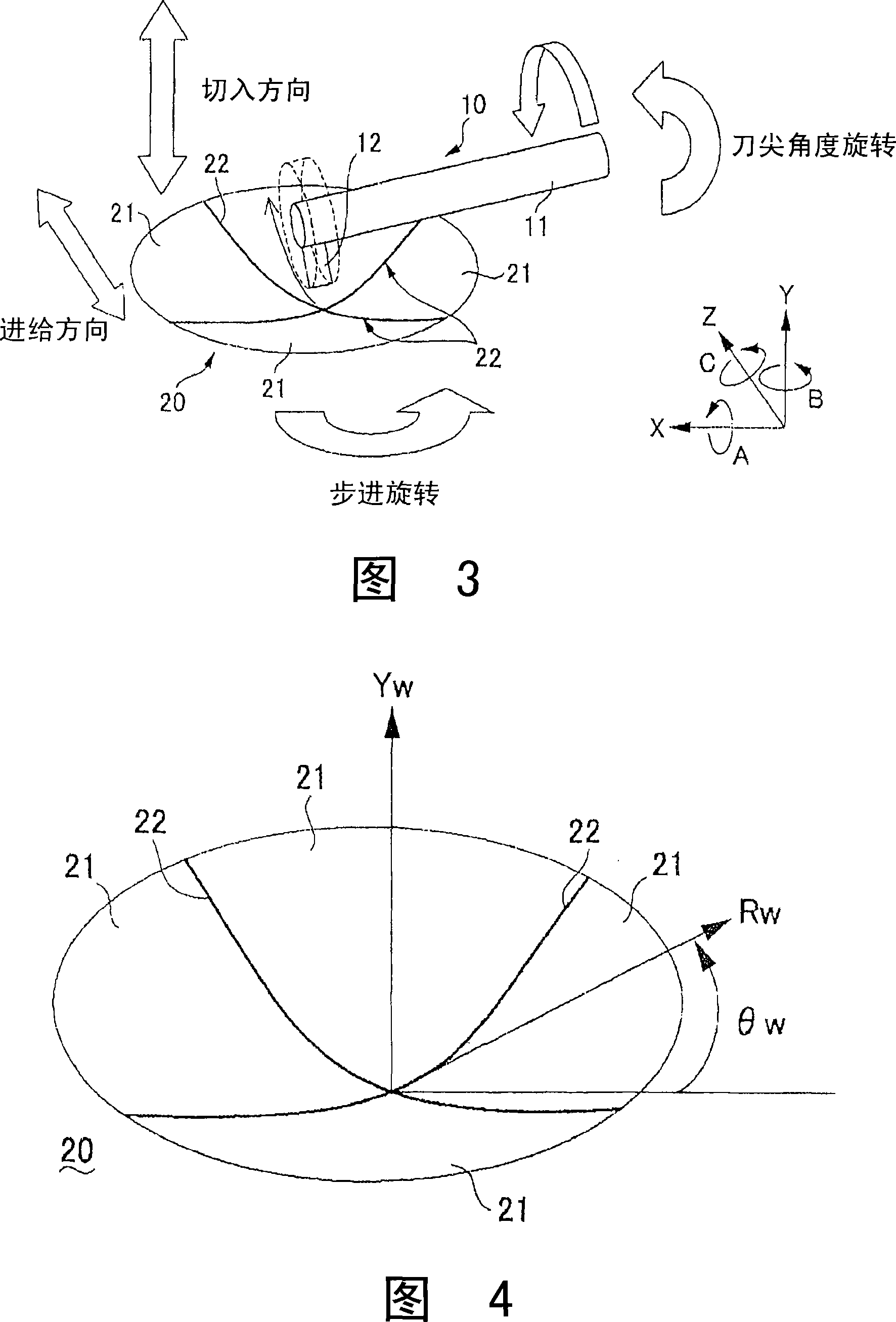

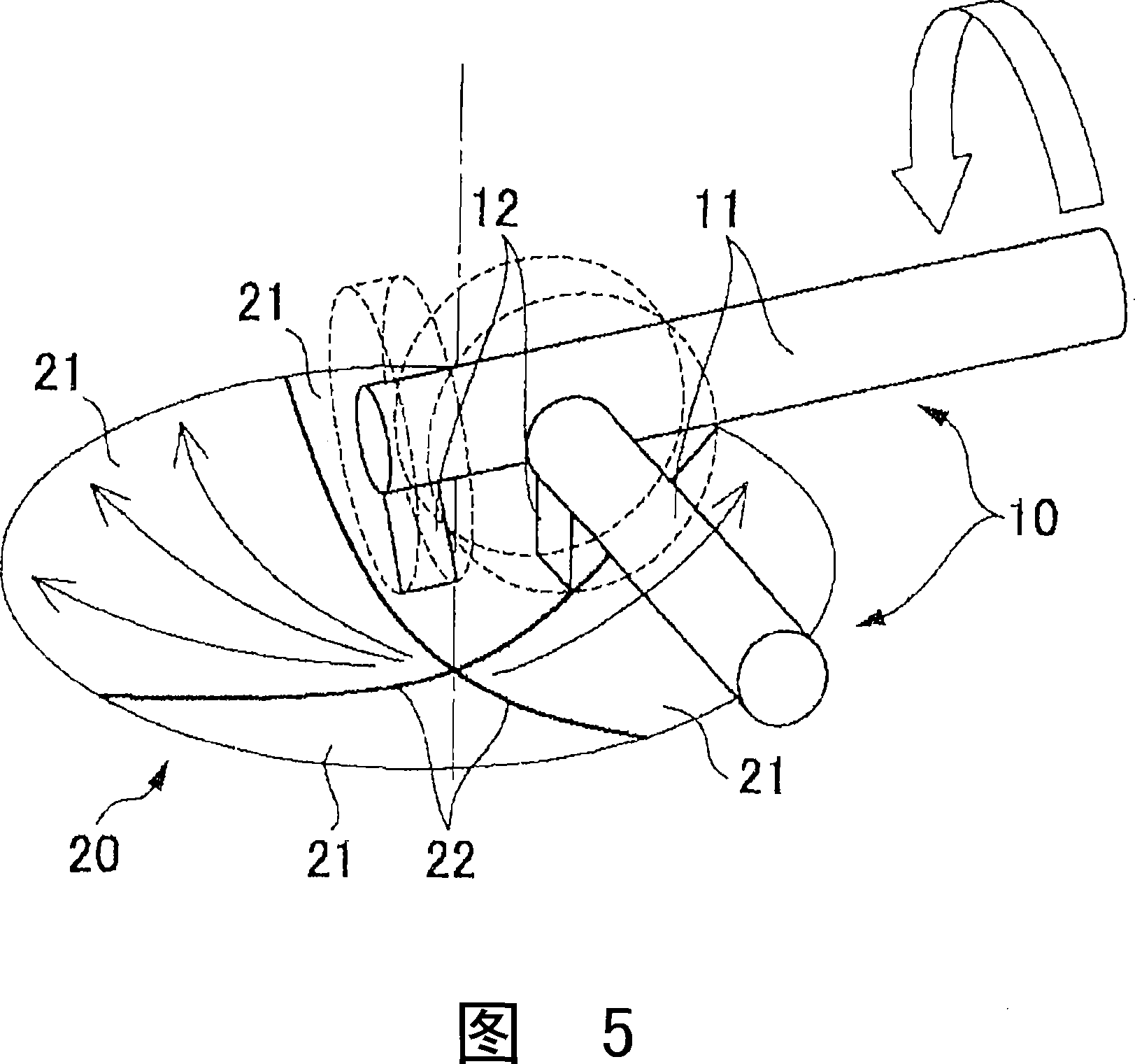

[0064] 1( a ) and ( b ) are explanatory views of an optical element according to the present invention and cross-sectional views of steps formed in the boundary region between the processed surfaces (element surfaces) of the optical element, respectively. Fig. 2 is an explanatory diagram of a flat flying knife. Fig. 3 is an explanatory view showing a processing method (manufacturing method of an optical element) according to Embodiment 1 of the present invention. Fig. 4 is an explanatory diagram of a cylindrical coordinate system used in the machining method of the present embodiment. Fig. 5 is an explanatory view at the time of processing a boundary portion in the processing method of the present embodiment. Fig. 6 is a cross-sectional view showing processing by the method shown in Fig. 5 .

[0065] In this embodiment, a flying knife protruding from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com