Method for fast stepless regulating and controlling cabinet storage capacity in storage cabinet system

A storage cabinet and capacity technology, used in storage devices, control/regulation systems, and simultaneous control of multiple variables, etc. problems, to achieve the effect of improving the utilization rate of storage cabinets, simple technical measures, and easy implementation of technical measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

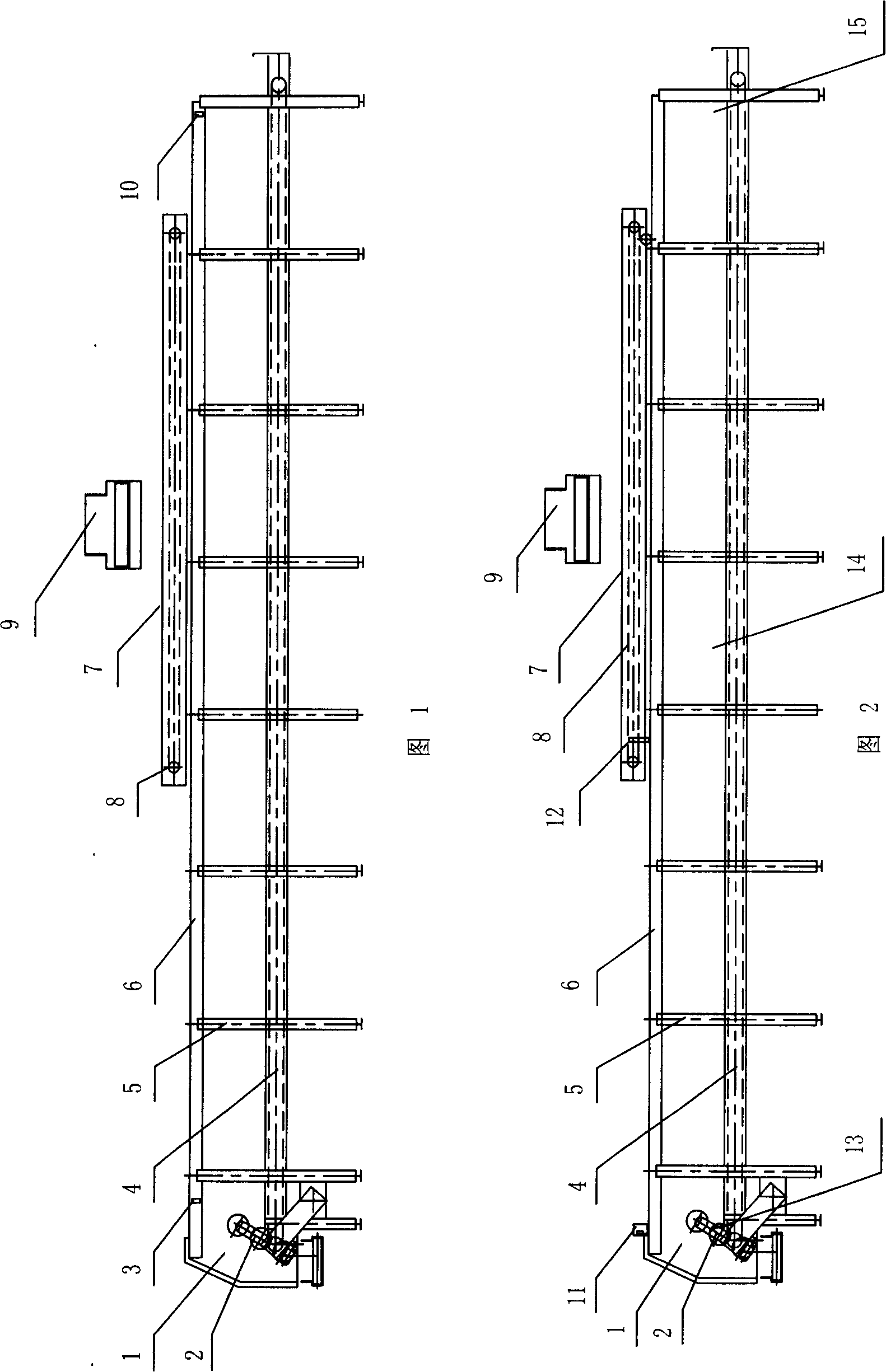

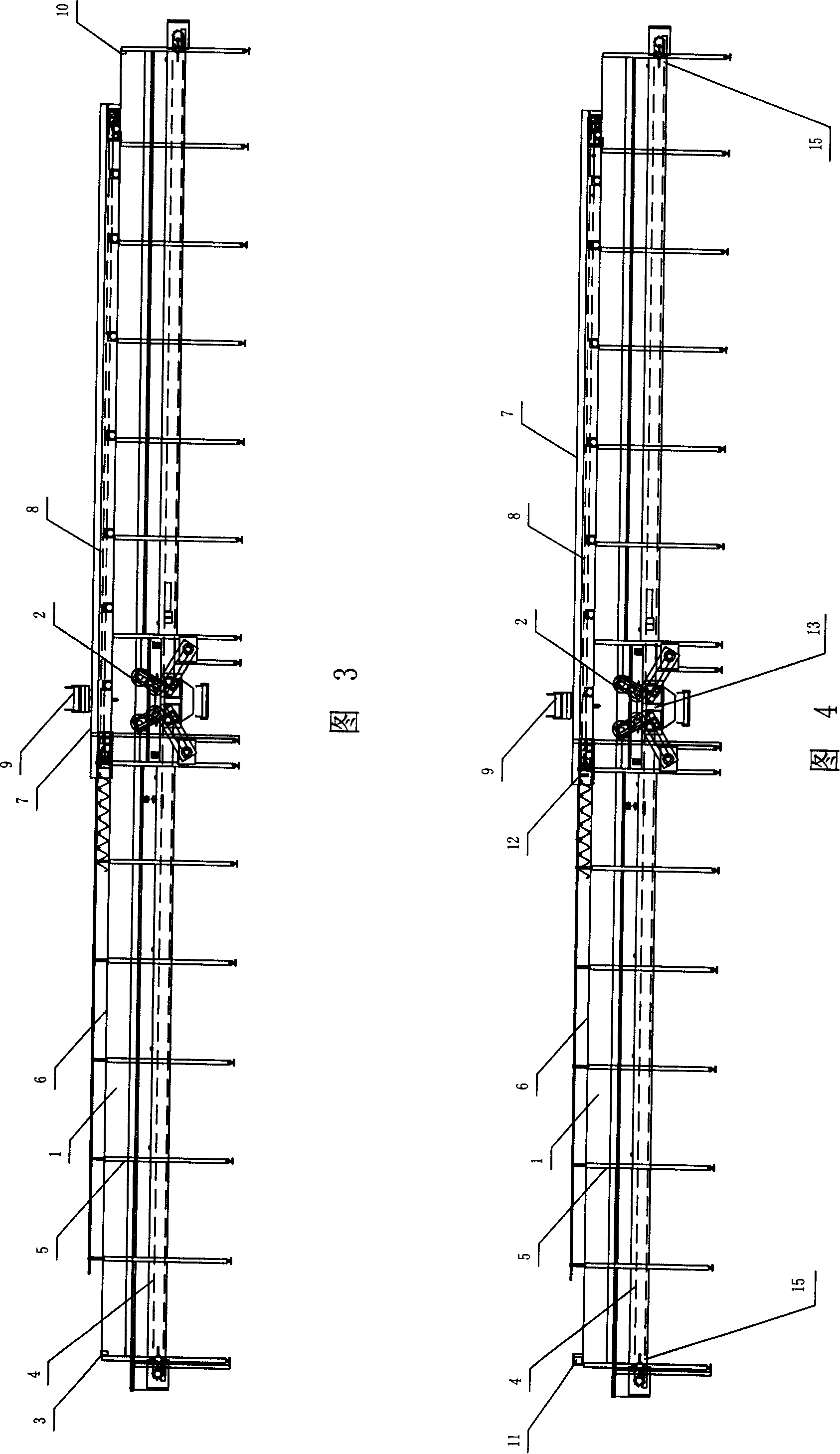

[0017] The specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing, accompanying drawing 1 is the structural representation of single storage cabinet system in the prior art, and the length of cloth cart 7 and cloth cart belt 8 is half of the length of cloth cart track 6 , the cloth cart 7 and the cloth cart belt 8 can run bidirectionally, and both running speeds and directions are the same. When distributing cart 7 pairs of single storage cabinet cloth in the prior art, its method is to be bounded by center point 14, between center point 14 to two proximity switches of cabinet head 13 and cabinet tail 15 (as 3 of accompanying drawing 1 , between 10), by the feeding end of cloth cart belt 8, to both sides cloth repeatedly (to two opposite direction cloths away from center point 14). Shown in accompanying drawing 2 is to apply the single storage cabinet system structural representation of the present invention, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com