Cylinder block

A technology of cylinder block and cylinder liner, which is applied in the direction of cylinder, cylinder head, engine components, etc., can solve the problem of high temperature of cylinder liner and push rod chamber, and achieve the effect of improving fluidity of casting liquid, shortening distance and reducing heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

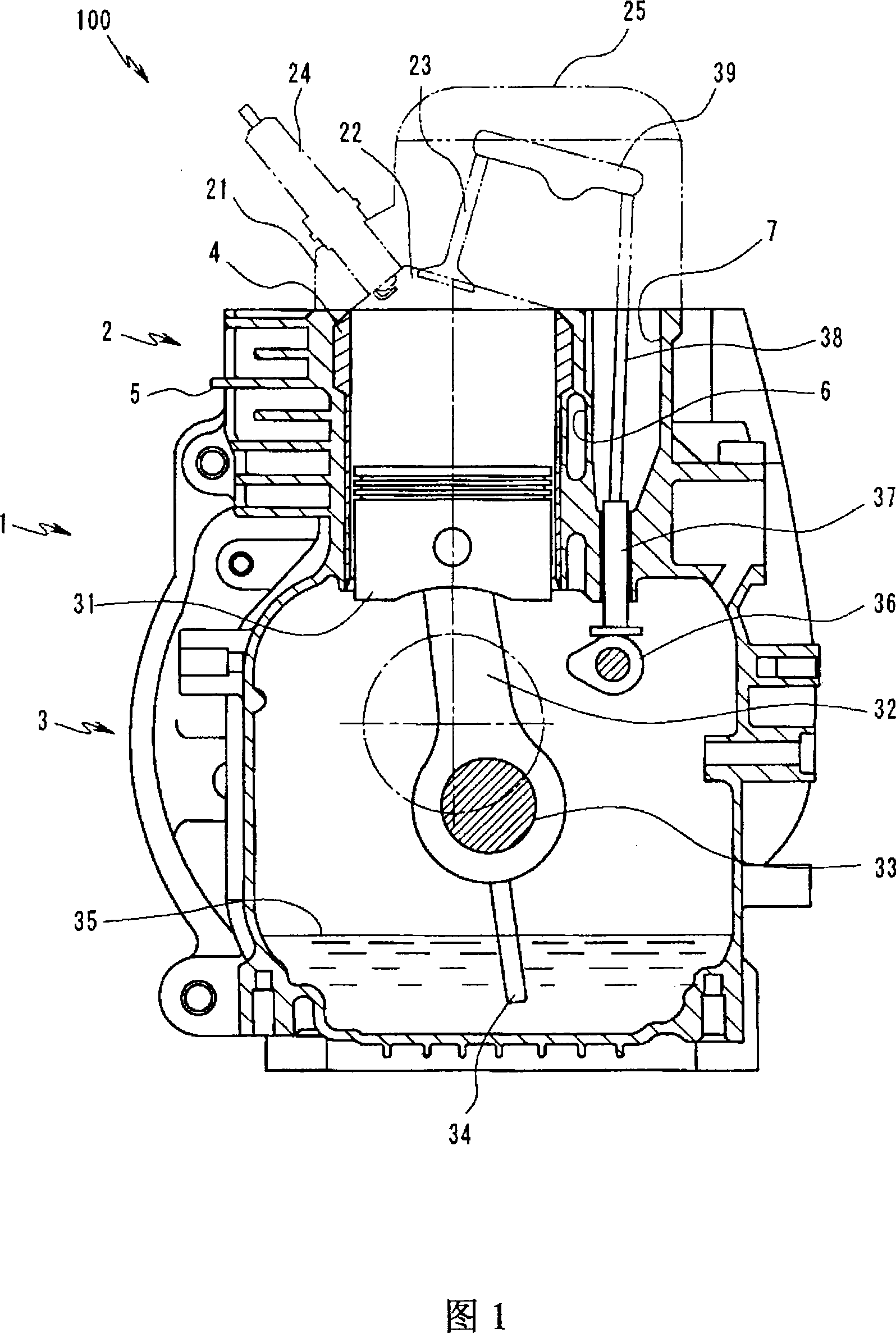

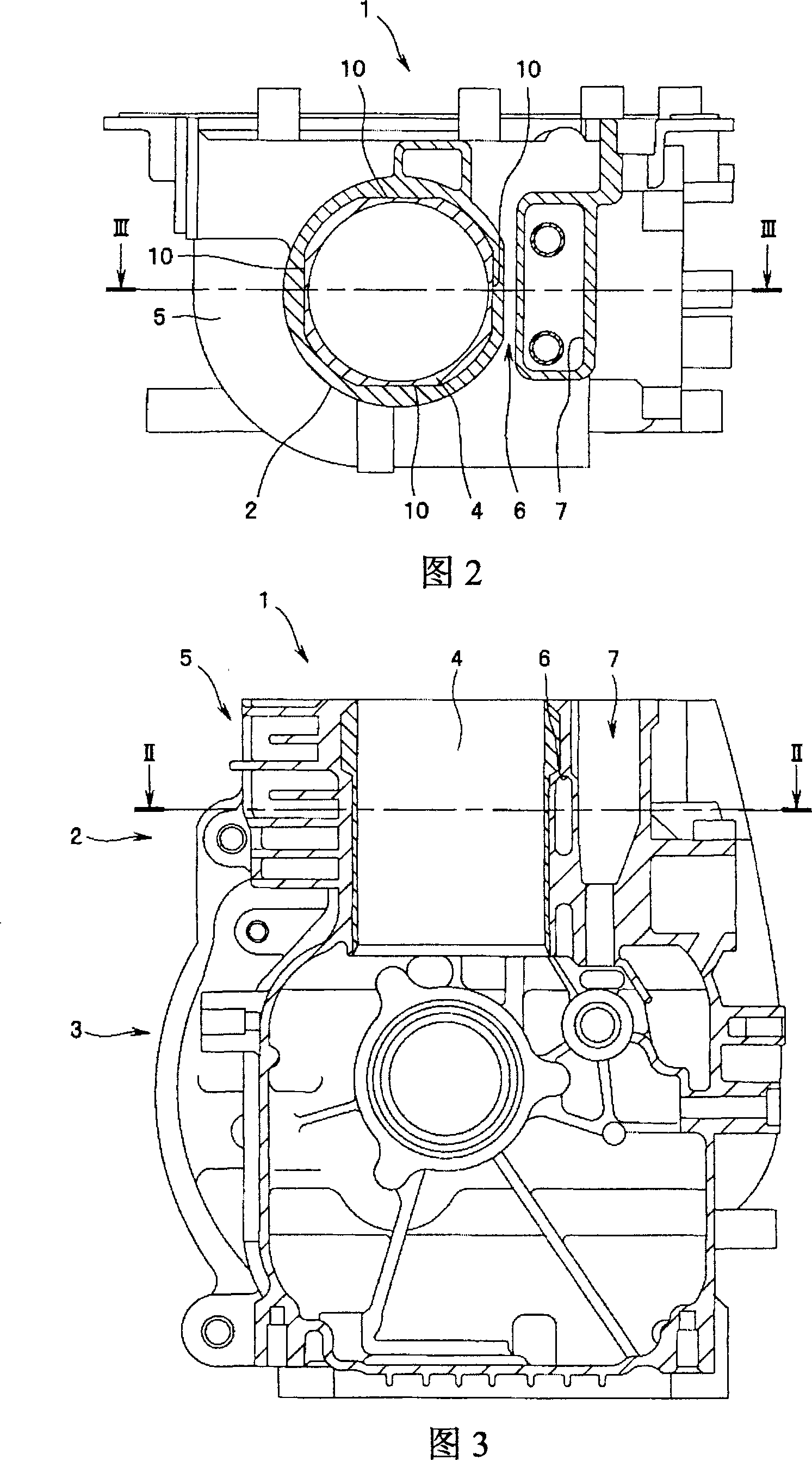

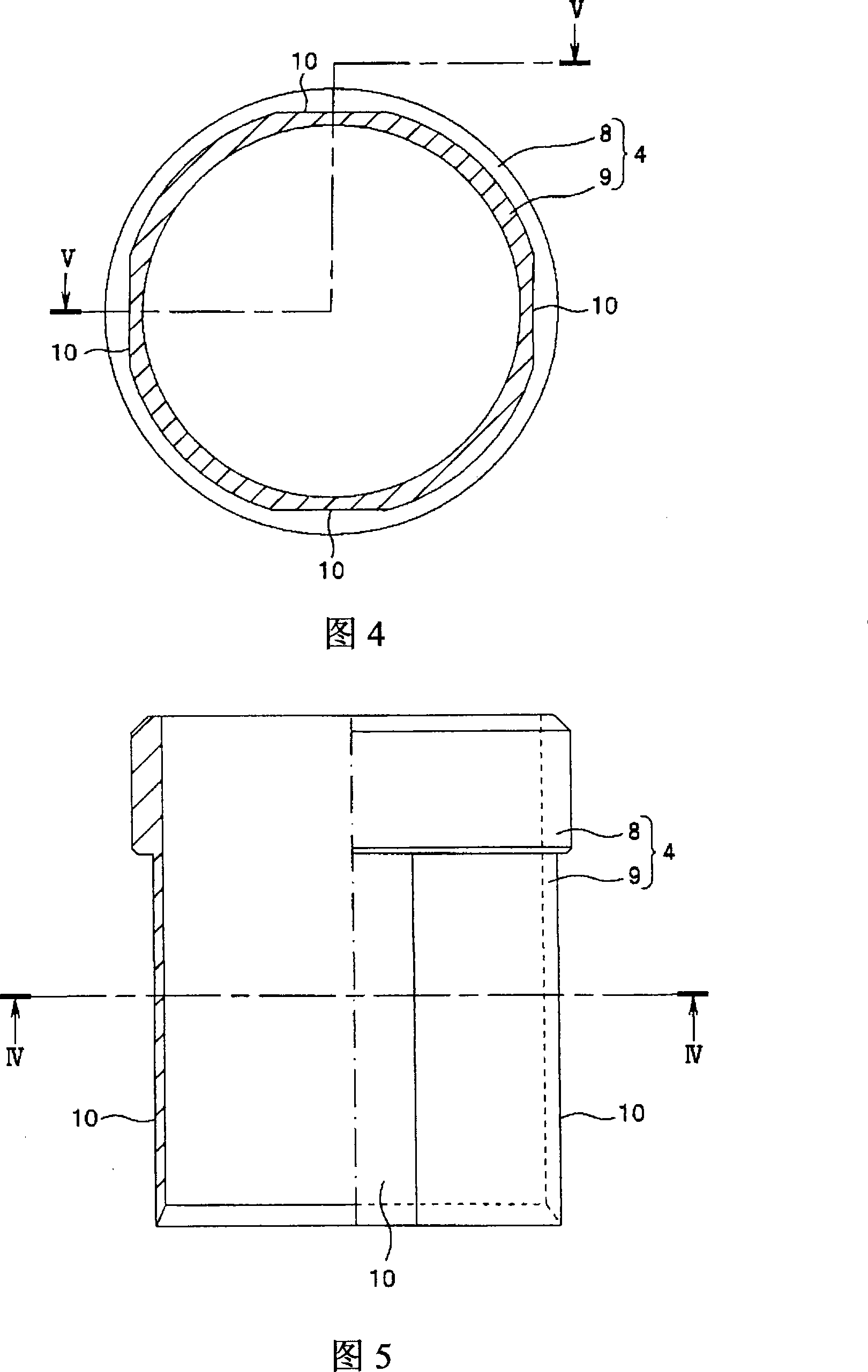

[0017] Hereinafter, an embodiment of an air-cooled OHV engine using the present invention will be described with reference to the drawings. Fig. 1 is a sectional view schematically illustrating the structure of an engine according to an embodiment of the present invention, Fig. 2 is a sectional view of a cylinder block taken along line II-II in Fig. 3 , and Fig. 3 is a sectional view taken along line III-III in Fig. 2 Figure 4 is a cross-sectional view of the cylinder liner cut along line IV-IV in Figure 5. Fig. 5 is a sectional view of the cylinder liner taken along line V-V in Fig. 4 .

[0018] The engine 100 is, for example, an air-cooled OHV single-cylinder 4-cycle general-purpose engine used in various applications such as generators, construction machines, and snowmobiles.

[0019] As shown in FIG. 1 , an engine 100 includes a cylinder block 1 in which a crankcase 3 is integrally formed below cylinders 2 and a cylinder head 21 is attached above the cylinders 2 . In add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com