Lens automated assembling system

A technology for assembling systems and lenses, applied in installation, optics, instruments, etc., can solve problems such as complex machine composition and limited space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Before presenting a detailed description, it is noted that in the following description, similar components are denoted by the same numerals.

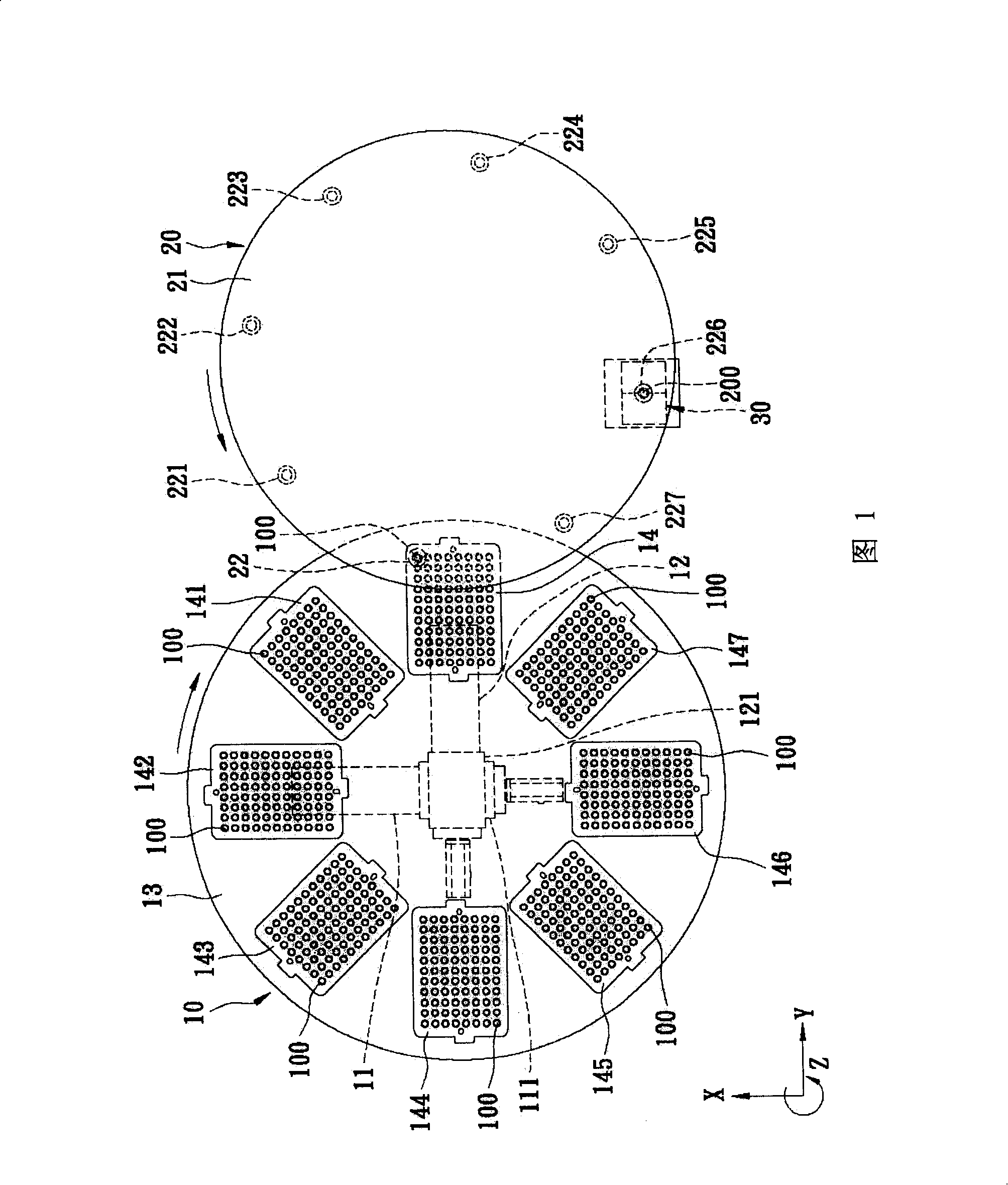

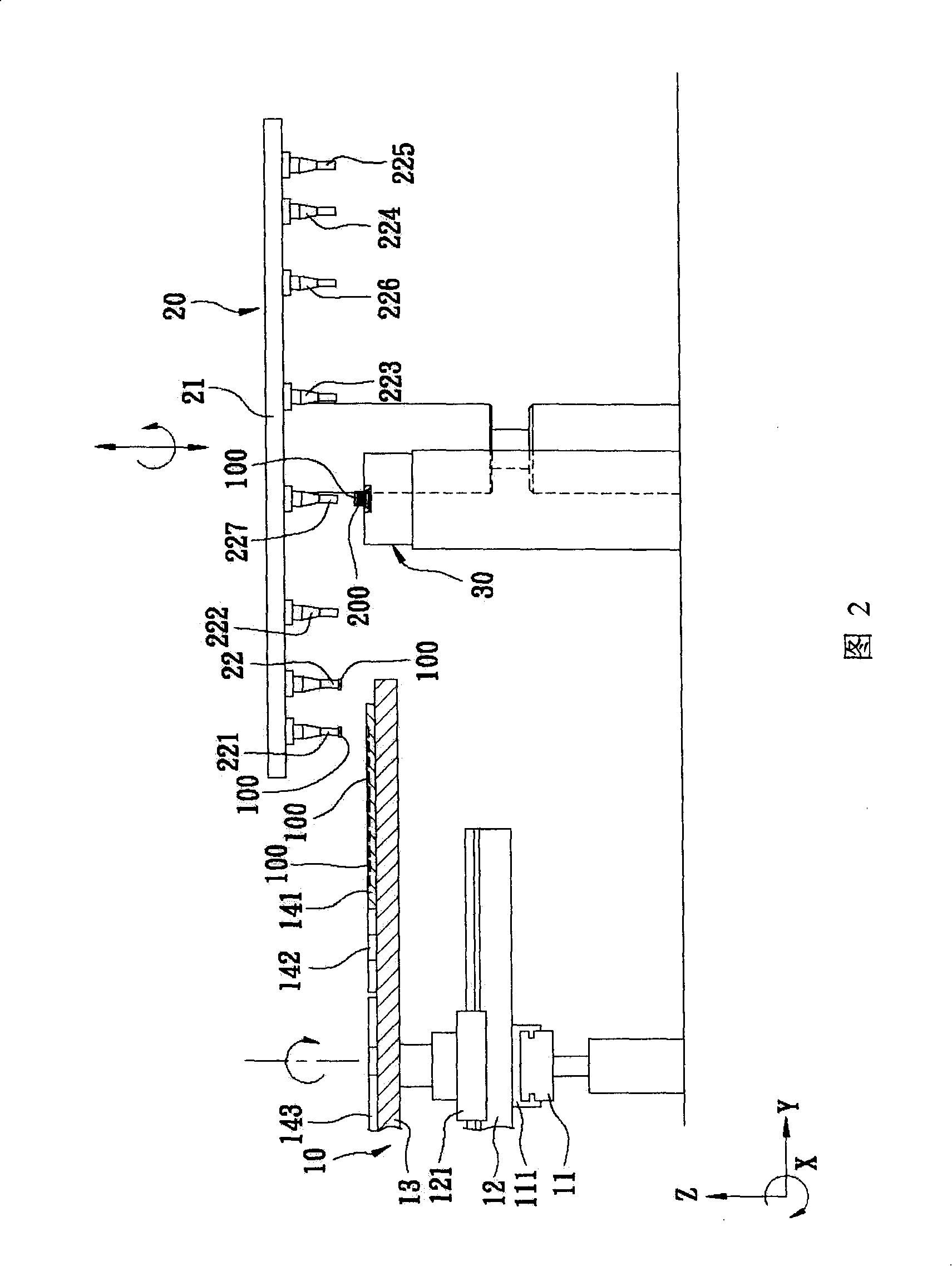

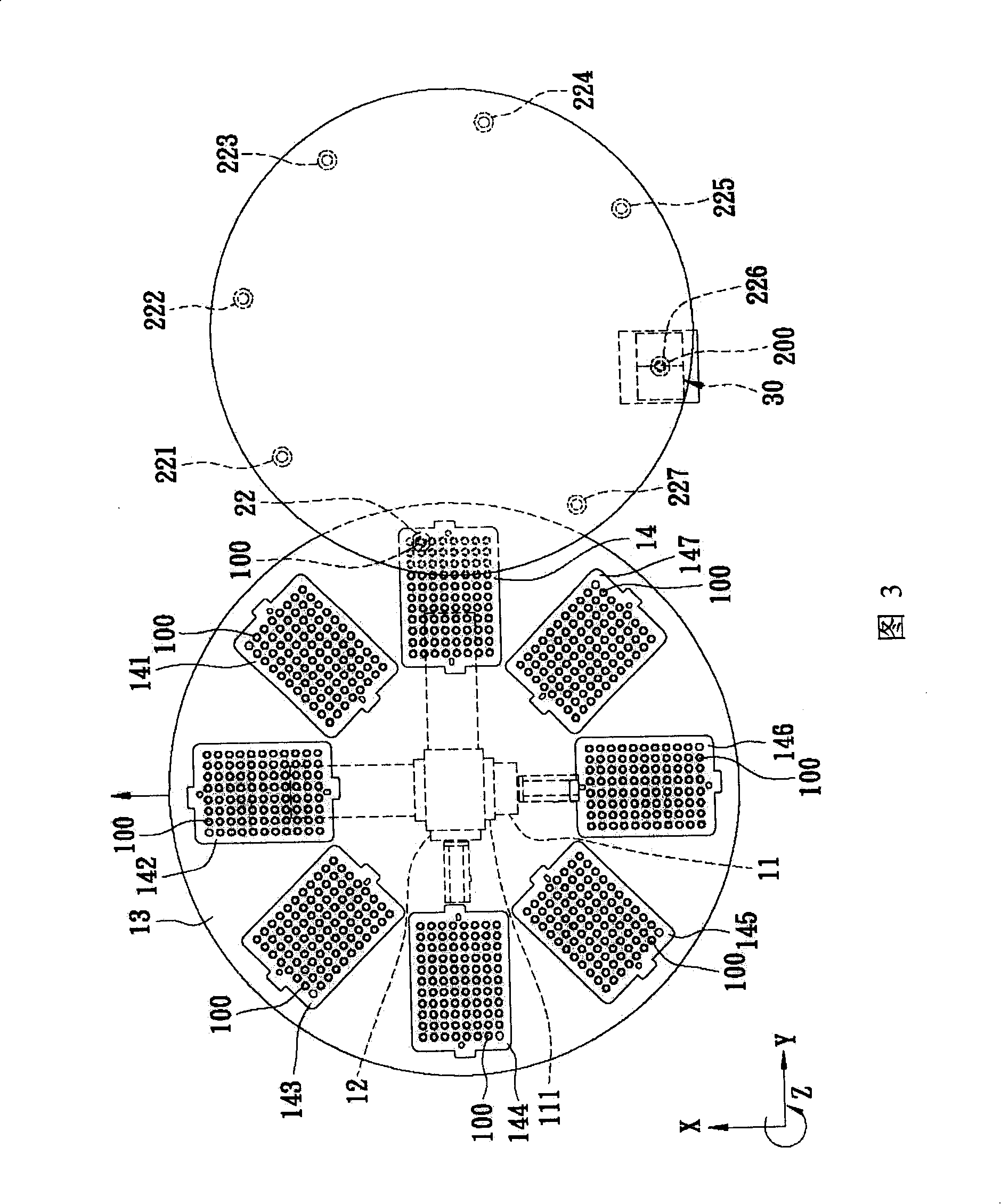

[0019] Referring to FIGS. 1 and 2 , it is a first preferred embodiment of the automatic lens assembly system of the present invention. The automatic assembly system includes: a component handling unit 10 , a component transfer unit 20 , and a jig 30 .

[0020] The component handling unit 10 has a first moving device 11, a second moving device 12 installed on the first moving device 11, a first rotating member 13 installed on the second moving device 12, and Eight bearing discs 14 , 141 , 142 , 143 , 144 , 145 , 146 , 147 are respectively disposed on the first rotating member 13 . The first moving device 11 has a first moving part 111 that can move along a first direction X. The second moving device 12 is mounted on the first moving part 111 and has a moving part 111 that can move along a direction perpendicular to the first dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com