Drawtube, optical module group with the same and its assembling method

A technology of optical modules and assembly methods, which is applied in the field of optical systems, can solve the problems of optical eccentricity measurement, inability to adjust, replace optical components, waste of assembly process, etc., and achieve a good clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The lens barrel of the technical solution, the optical module having the lens barrel, and the method for assembling the optical module will be described in detail below with reference to several drawings and multiple embodiments.

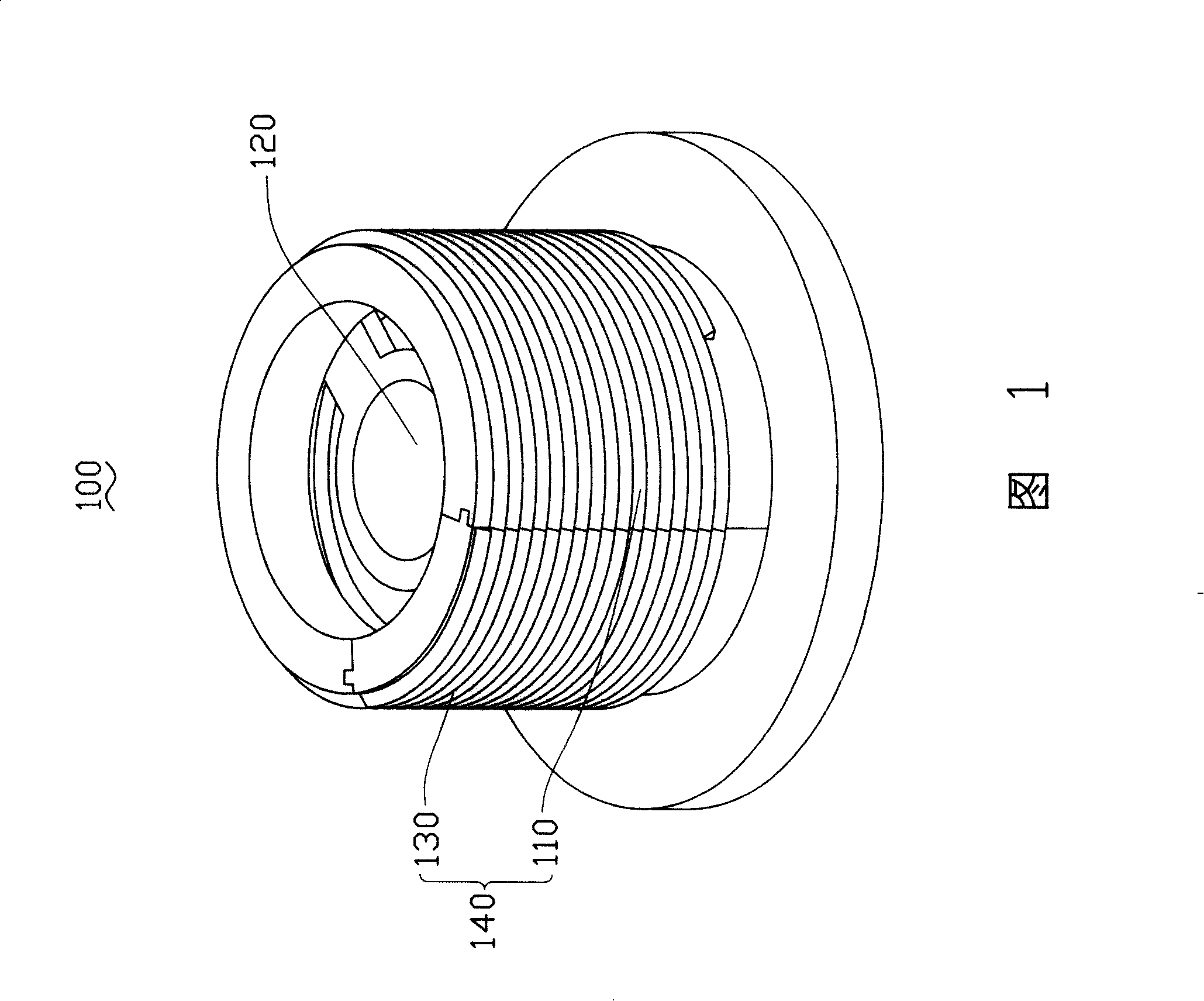

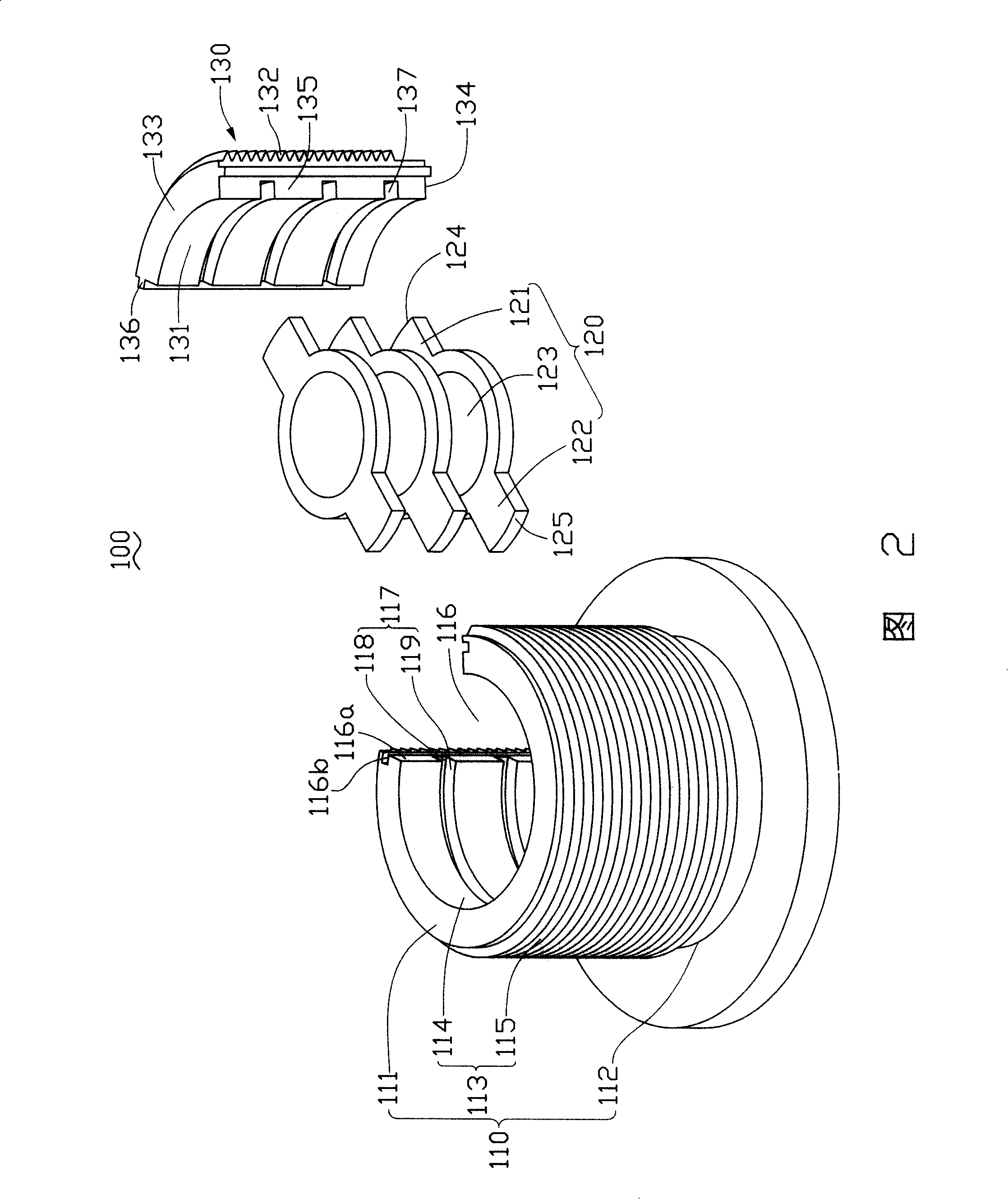

[0016] As shown in FIG. 1 , the first embodiment of the technical solution provides an optical module, such as an optical lens module 100 . The optical lens module 100 includes a lens barrel 140 and at least one lens 120 . Of course, the optical lens module 100 can also generally include components such as aperture plates, optical filters, and spacer rings. In order to describe the structure of the optical lens module 100 simply and clearly, the present embodiment only installs a plurality of lenses 120 in the lens barrel. The structure of the optical lens module 100 will be described as an example. The lens barrel 140 includes a lens barrel body 110 and a sealing device 130 .

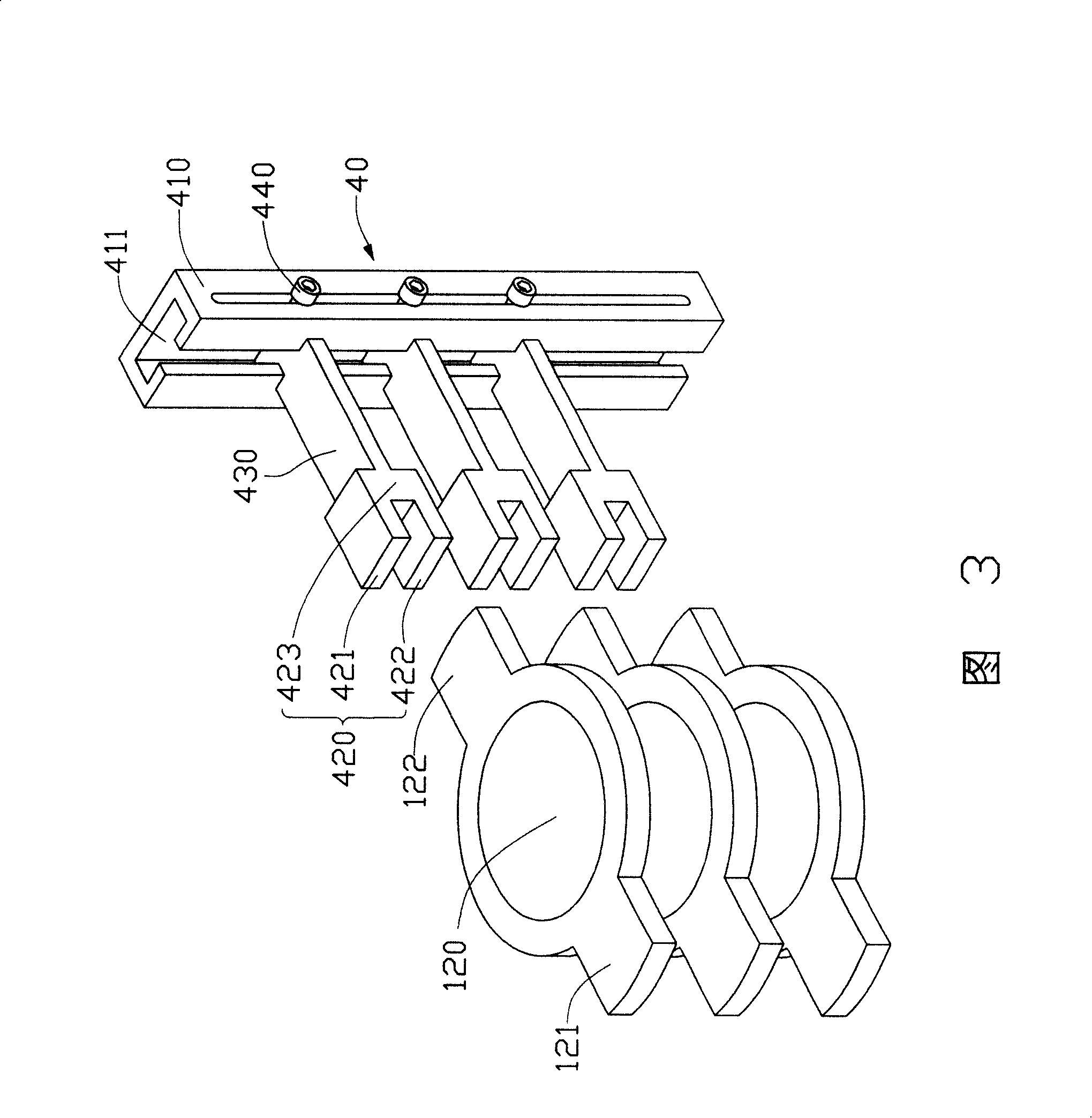

[0017] As shown in FIG. 2 , the lens barrel body 110 has a fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com