Centrifugal device comprising improved process analysis technology

A centrifuge and filter technology, which is applied in the field of centrifuges, can solve the problems of hindering the flushing fluid from washing the filter cake, and can not be determined, so as to achieve the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

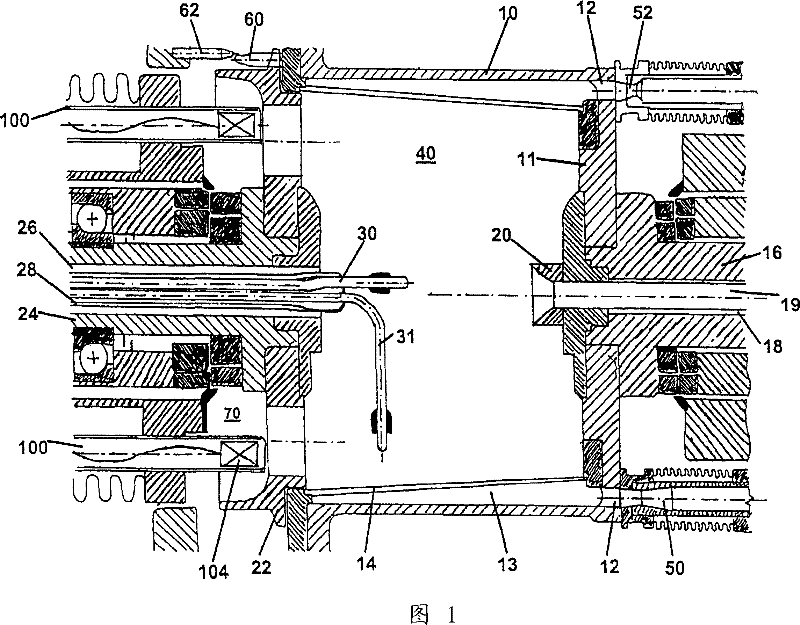

[0069] figure 1 Shown is the working chamber 40 and the filter 14 surrounding it. Filter 14 is a metal filter made of rigid material and has the shape of a cone. A drum 10 is disposed around the filter and includes holes 12 in the bottom of the drum. An annular space 13 is formed between the filter 14 and the drum 10 . One end of the working chamber 40 is formed by the bottom of the drum 10 , which is supported on the drive shaft 16 . The drive shaft 16 is hollow and has a drive shaft channel 18 therein, which serves as a filling channel for injecting a suspension. The funnel-shaped member 20 is connected to the drive shaft channel 18 . The baffle shaft 24 is located opposite the drive shaft 16 and the baffle 22 is supported on the baffle shaft. The flap shaft 24 is hollow and has a PAT channel 26 in it. In the PAT channel 26 a sleeve 28 in which three tubes 30 , 31 , 32 are housed extends. exist figure 1 Two of the three tubes 30, 31, 32 can be seen in FIG.

[0070] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com