Ultrasonic salt atomization method for accelerating spirit ageing

A well-established ultrasonic atomization technology, applied in the field of ultrasonic salt atomization, can solve problems such as occupancy pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

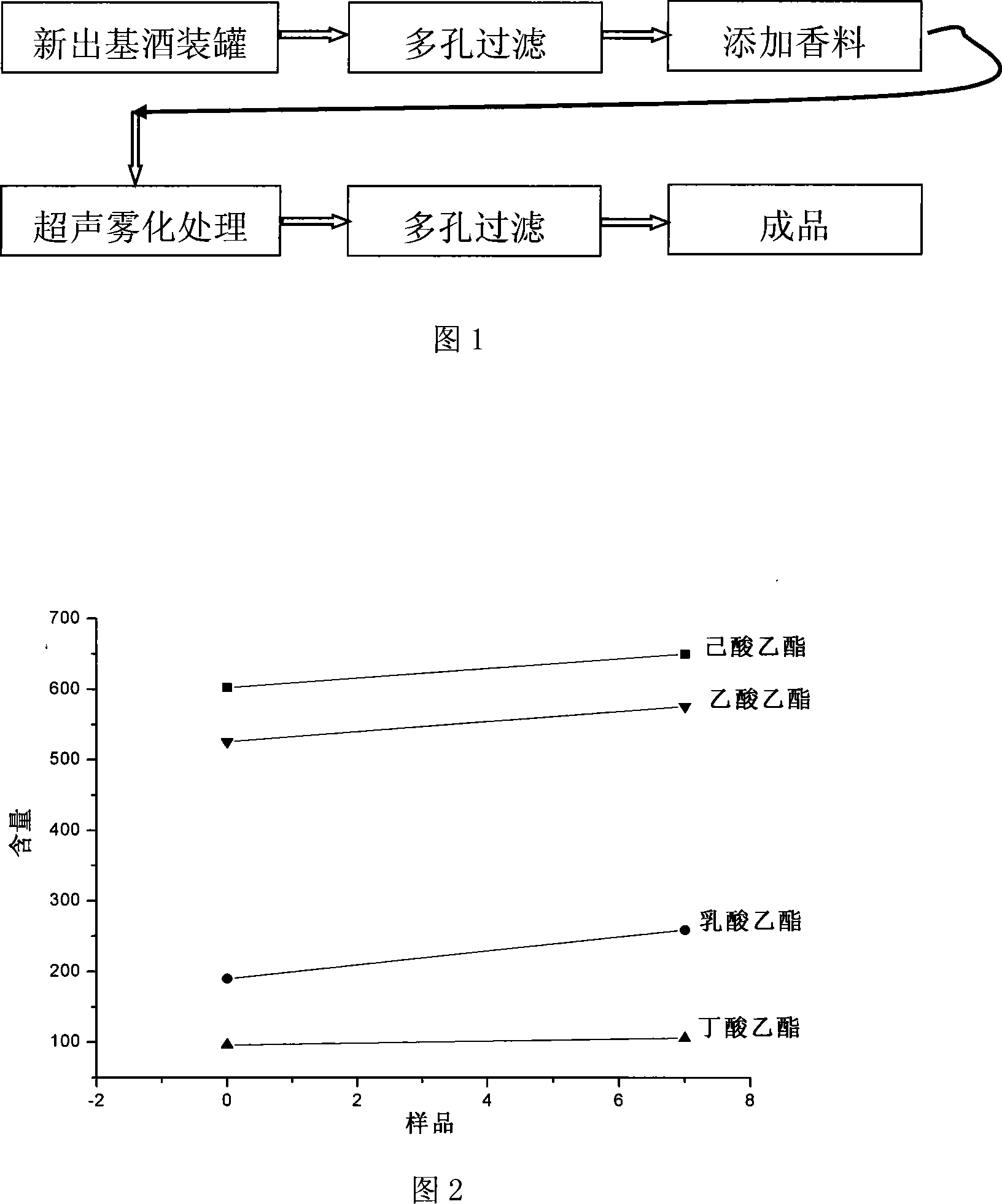

[0025] Embodiment 1-handling Daoguang 25 Manchu Brewing Co., Ltd. new base wine

[0026] The condition is to use SiC porous ceramics (pore size: 20μm) with TiO on the surface 2 Catalyst, ultrasonic frequency 25kHz, processed without any fragrance. Table 1 is the results before and after treatment given by the sommelier after tasting, and Table 2 is some physical and chemical indicators. After being treated by the invention, the physicochemical and mouthfeel of the wine are changed, especially for the new base wine, after the treatment, the pungency and irritation are obviously reduced, and the total acid and total fat are increased. Moreover, after tasting by the expert group, it is believed that the processed sample is mellow, mellow, soft, less irritating and spicy than the new base wine, and has reached the level of more than 2 years of storage in clay pots.

[0027] sample

[0028] Table 1 Expert Evaluation Results

[0029] sample ...

Embodiment 2

[0031] Embodiment 2-handling Daoguang 25 Manchu Brewing Co., Ltd. new base wine

[0032] The condition is to use Al 2 o 3 Porous ceramics (pore size: 580μm) with TiO hanging on the surface 2 Catalyst, ultrasonic frequency 20kHz, different spices were added according to different requirements of the manufacturer before ultrasonic atomization treatment. Table 3 is the results before and after treatment given by the sommelier after tasting, and Table 4 is some physical and chemical indicators. After the treatment of the invention, the physicochemical properties and mouthfeel of the wine are changed, especially for the new base wine, after the treatment, the wine body is soft, mellow, sweet and delicious. After tasting, the expert group believed that the processed samples were mellow, mellow, and supple, without the bursting feeling of the new base wine, and the effect can reach the level of more than 2 years of storage in clay pots.

[0033] sample

[0034] ...

Embodiment 3

[0037] Example 3 - Treatment of new base liquor from Jiangsu Jinshiyuan Brewing Company

[0038] The condition is to use SiC porous ceramics (pore diameter: 2mm), with catalyst activated carbon hanging on the surface, control the ultrasonic frequency at about 50kHz, and process without adding any fragrance. Table 5 is the results before and after treatment given by the sommelier after tasting, and Table 6 is some physical and chemical indicators. After being treated according to the solution of the present invention, the aroma of the cellar is strong, the aroma is outstanding, the aroma is sweet and clear, and the aroma remains in an empty cup. After evaluation by the expert group, it is believed that the effect can reach the level of clay pot storage for more than 3 years.

[0039] sample

[0040] Table 5 Expert Evaluation Results

[0041] sample

[0042] Table 6 physical and chemical test results

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com