High-altitude bridge type cantilever scaffold

A scaffolding and suspension technology, applied in the field of scaffolding, can solve the problems of occupying a large space on the ground and in the air, affecting the construction of other stations, and high-altitude operations, so as to ensure the three-dimensional intersection construction, light weight, and reduce duplication of labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

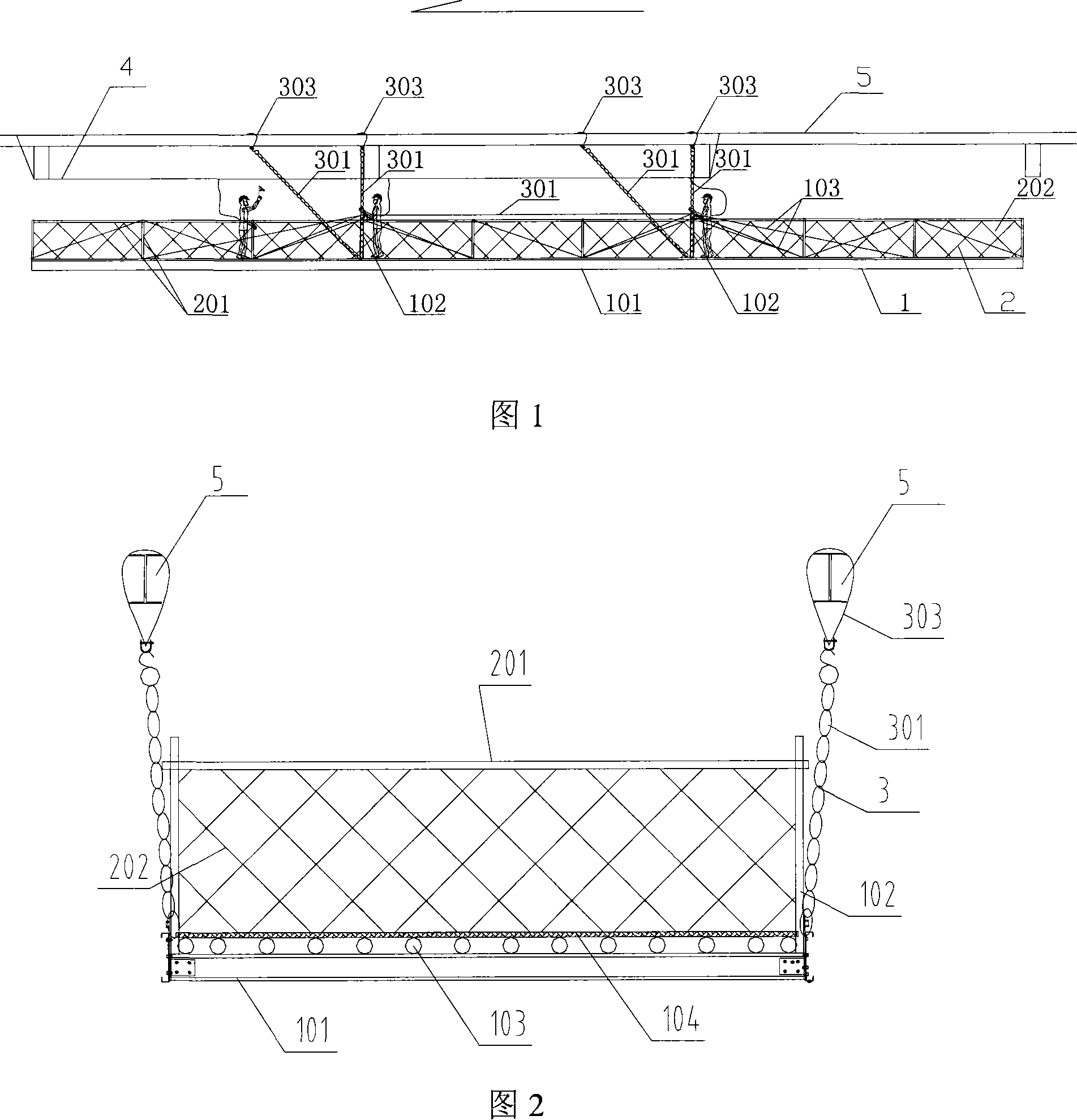

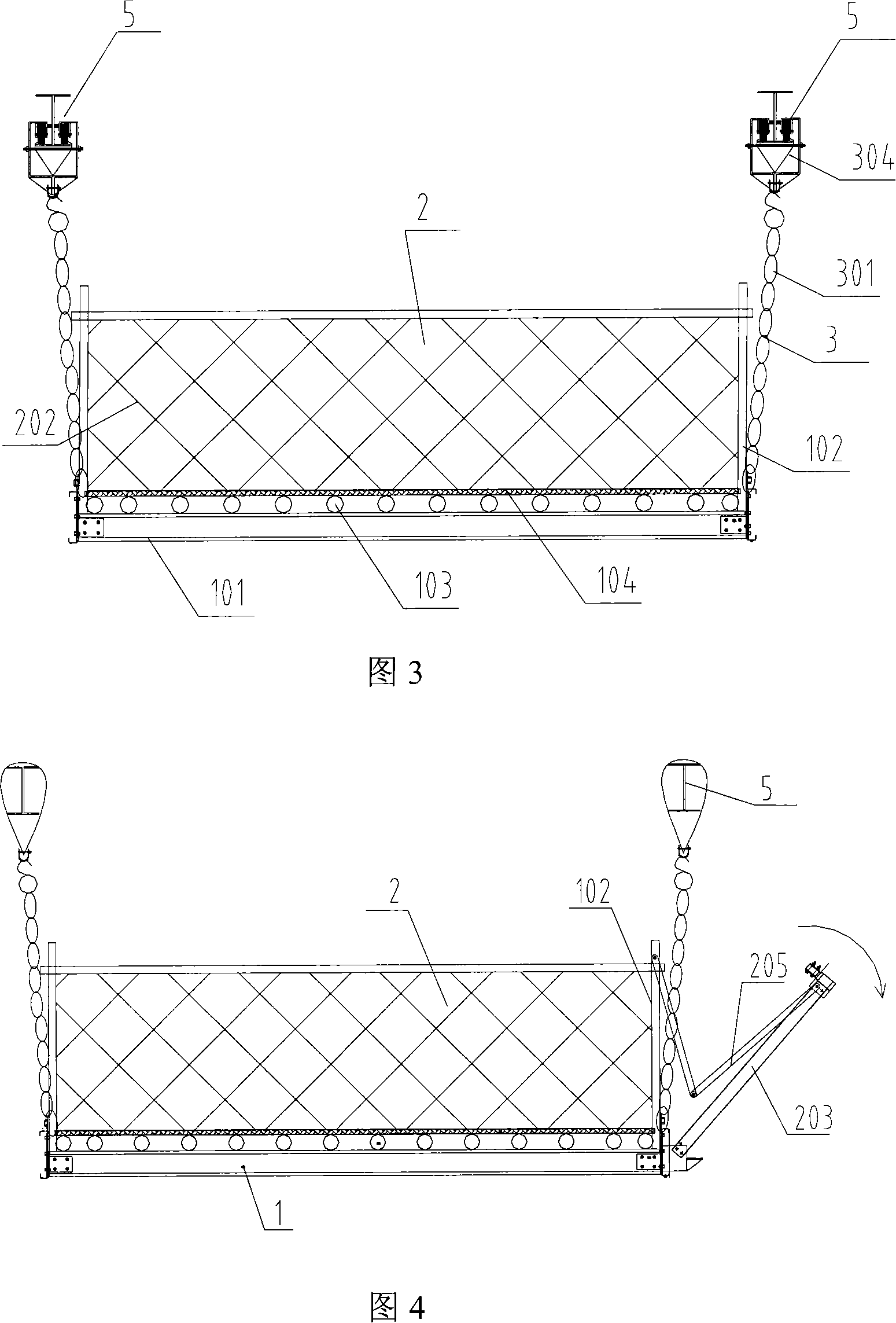

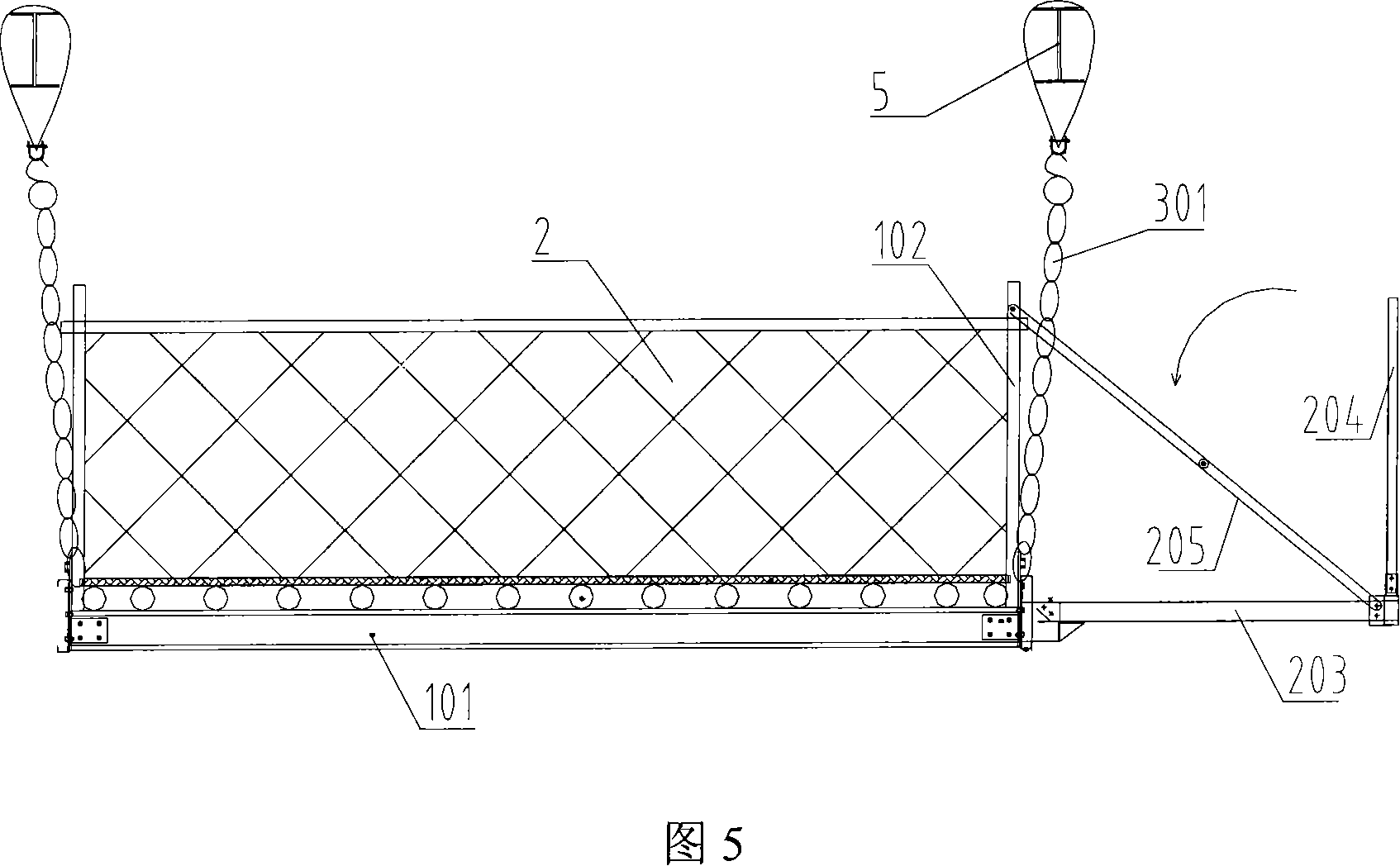

[0018] Further illustrate the present invention below in conjunction with accompanying drawing.

[0019] As shown in Fig. 1 and Fig. 2, a kind of high-altitude bridge type suspended scaffold of the present invention, its upper end is suspended on the steel beam 5 of building structure, comprises scaffold frame 1, guardrail 2 and hanger 3, and described scaffold frame 1 It includes a bottom frame 101, guardrail columns 102 on both sides, and cable-stayed steel wire ropes 103; the guardrail 2 includes horizontal and vertical guardrail steel pipes 201 that are fastened to the guardrail columns to form a truss and an external dense mesh 202, and the cable-stayed steel wire ropes One end of 103 is connected to the upper end of the guardrail column 102, and the other end is connected to the connection node between the bottom frame and the longitudinal guardrail steel pipe. The bottom frame 101, the guardrail column 102, and the guardrail steel pipe 201 form a truss through the stay c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com