Synchronization controller for wheel pair speed of engine static-state test platform

A synchronous control and mechanical synchronization technology, which is applied to controllers with specific characteristics, electric controllers, and comprehensive factory control, etc., can solve problems such as no automatic control of synchronous rotating devices, failure to meet production requirements, and lack of adjustment accuracy. To achieve the effect of comprehensive functions, convenient maintenance and good followability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

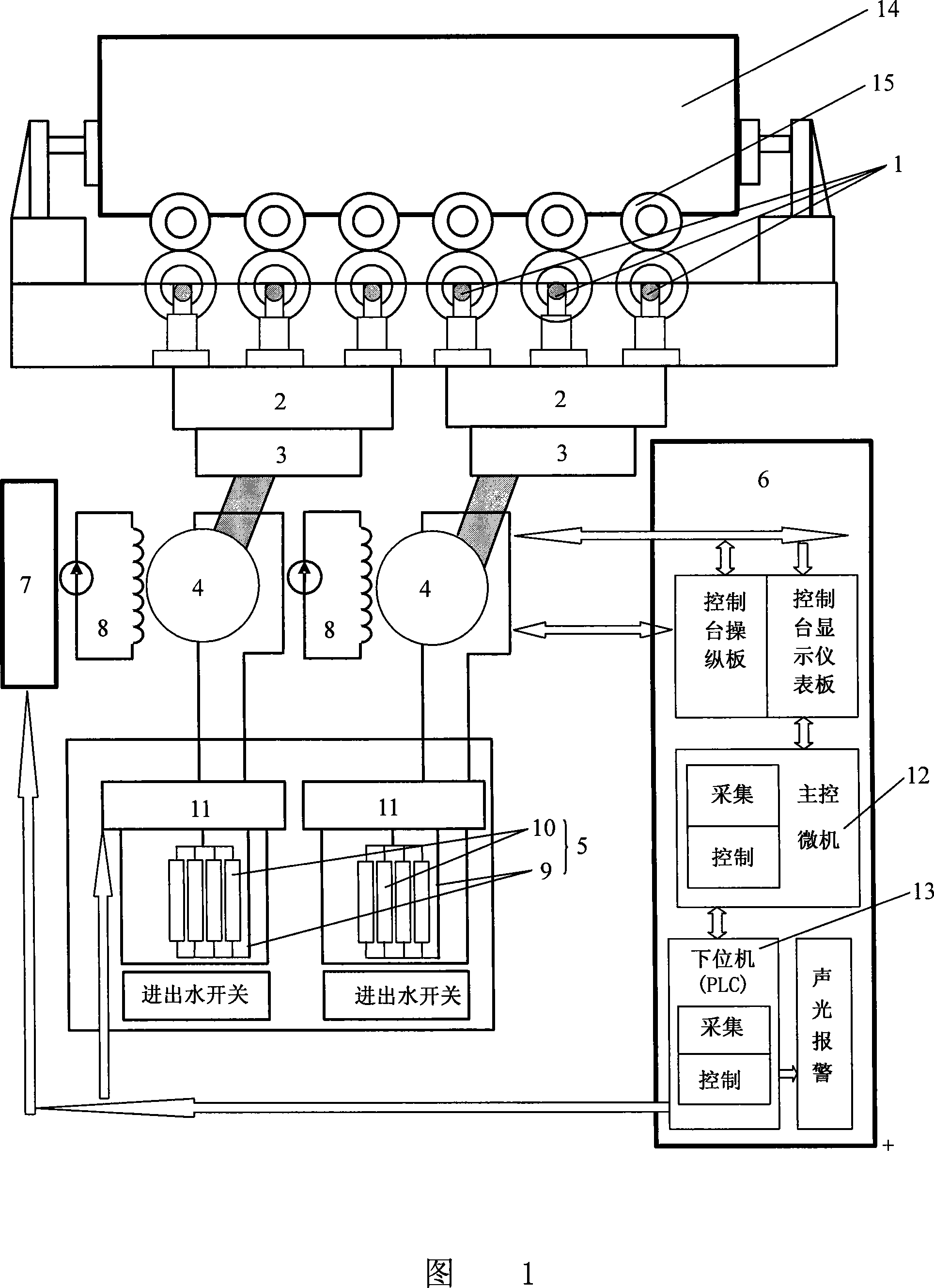

[0020] The present invention will be described in detail below according to the embodiments of the present invention and in conjunction with the accompanying drawings.

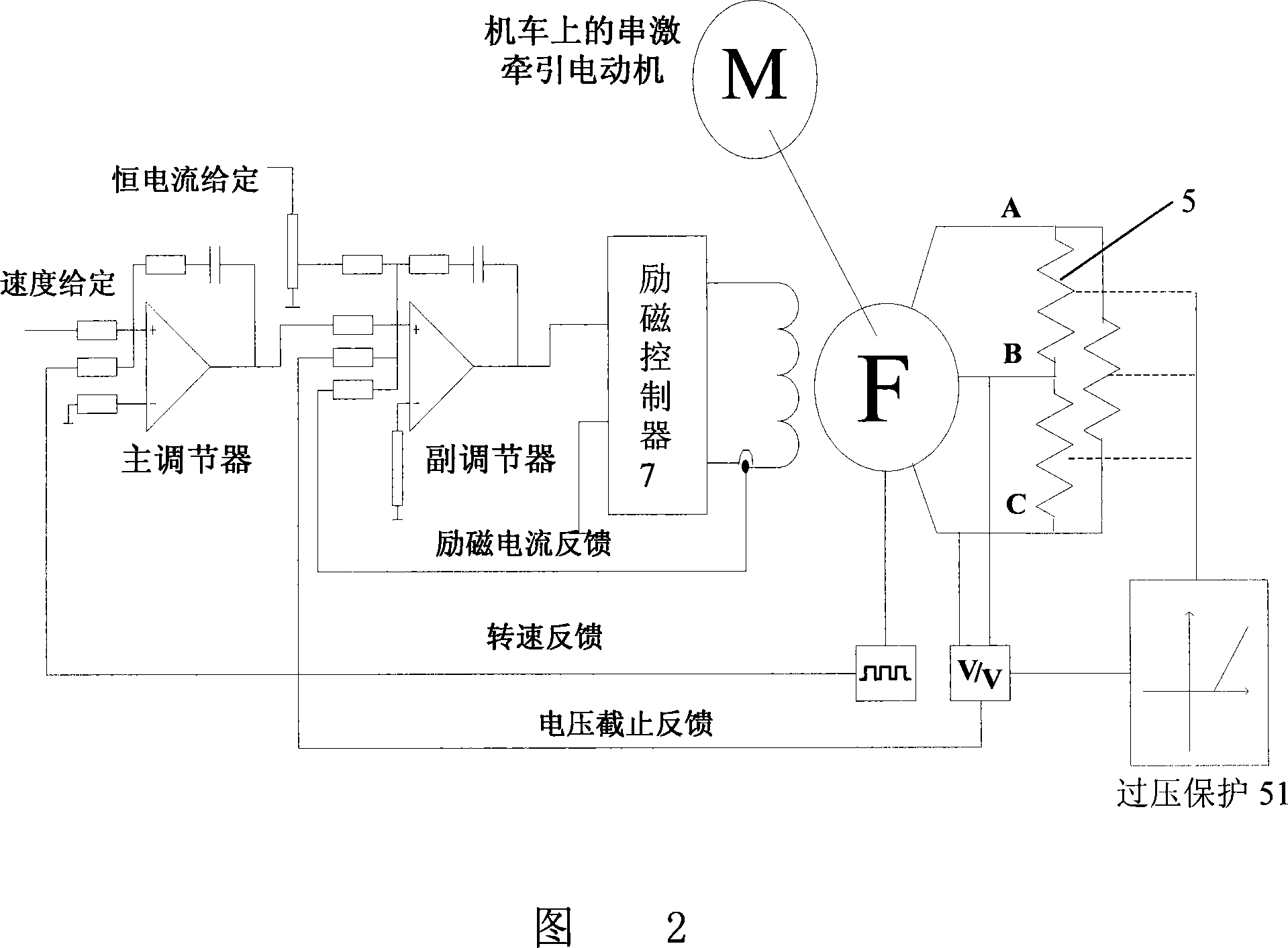

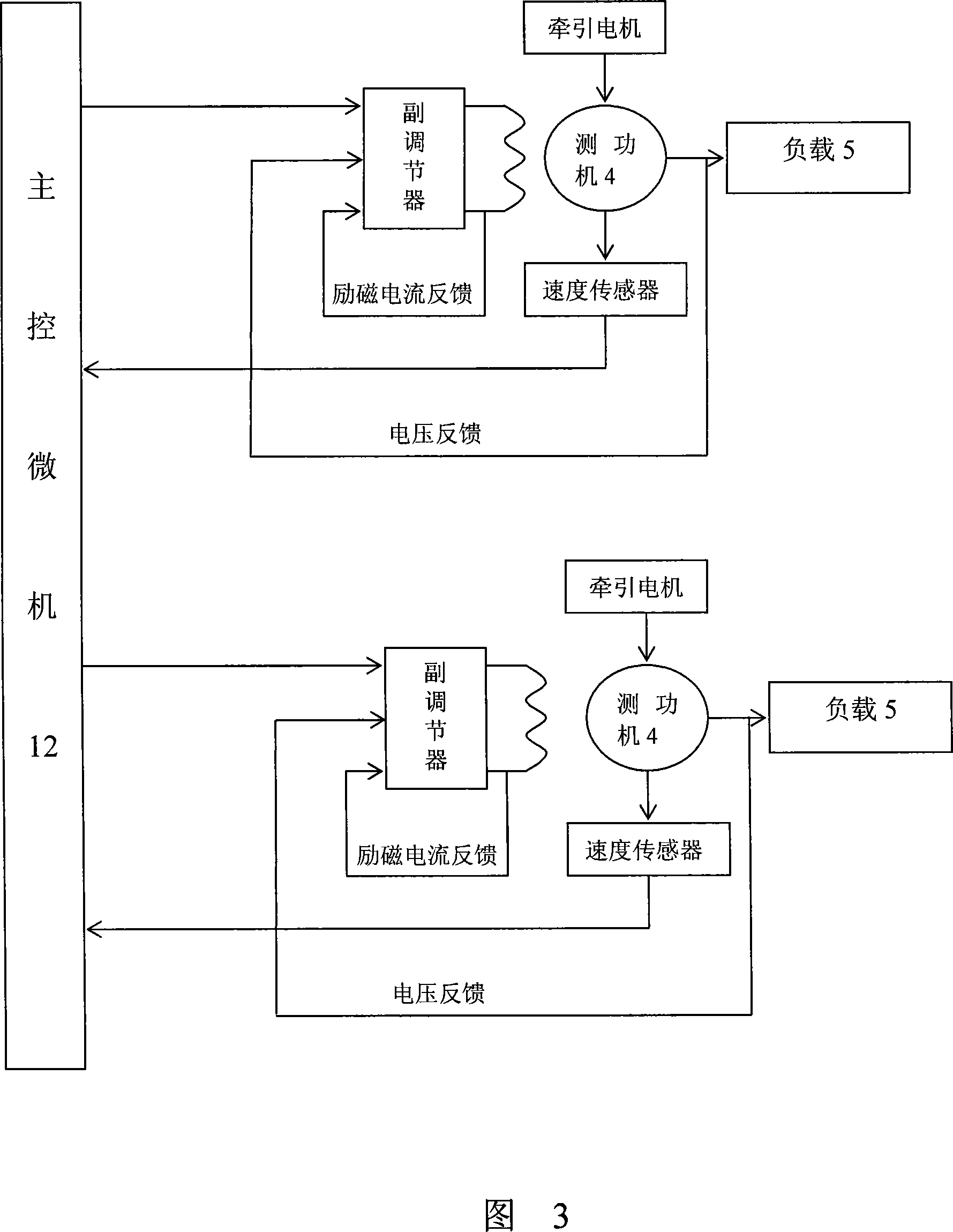

[0021] As shown in Fig. 1, the present invention includes six pairs of oppositely arranged axles 1, and every three pairs of axles 1 are connected into a mechanical synchronous system 2, and each mechanical synchronous system 2 is respectively connected with a transmission system 3, and the two transmission systems 3 are respectively connected with a measurement The dynamometer 4 and the second dynamometer 4 are connected to a load 5 respectively. The synchronous control system 6 is connected with the second dynamometer 4 and the second load 5 , and is connected with an excitation controller 7 that controls the rotation speed of the dynamometer 4 .

[0022] Each mechanical synchronization system 2 includes three pairs of wheel shafts 1, one pair of wheel shafts corresponds to a pair of track wheels, and each w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com