Glue film and chip encapsulation manufacture process using the glue film

A technology of chip packaging and adhesive film, which is applied in the direction of film/sheet adhesives, adhesives, and other chemical processes, and can solve the problems of lowering process yield and inability to maintain the height of the first chip, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

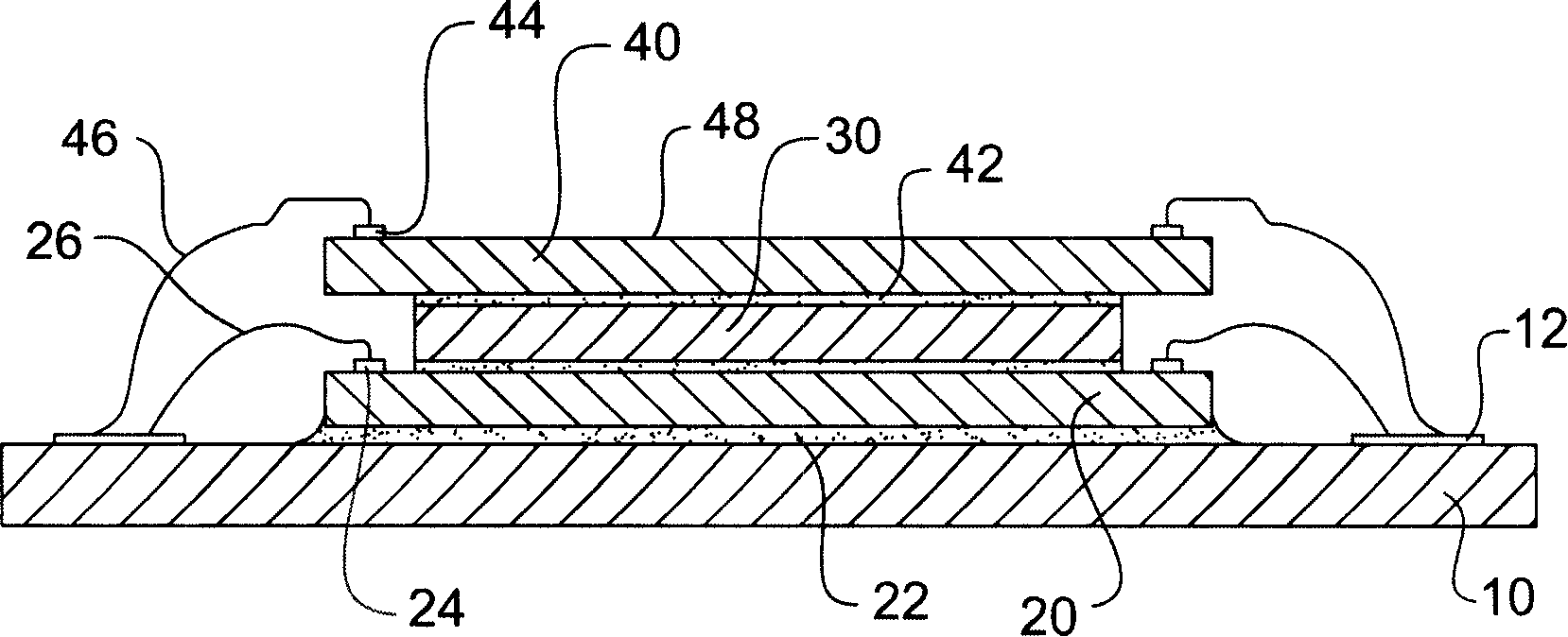

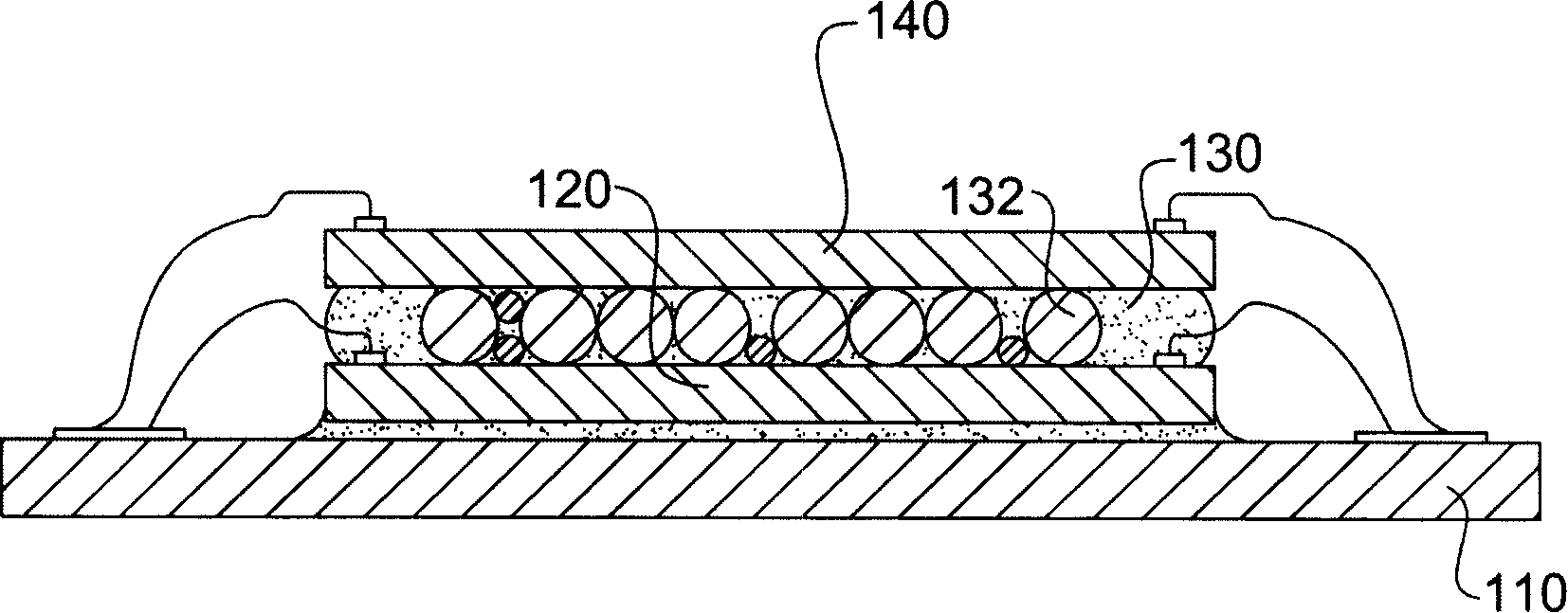

[0041] In order to make the above and other objects, features and advantages of the present invention more apparent, the following specifically cites the embodiments of the present invention, together with the accompanying drawings, for a detailed description as follows.

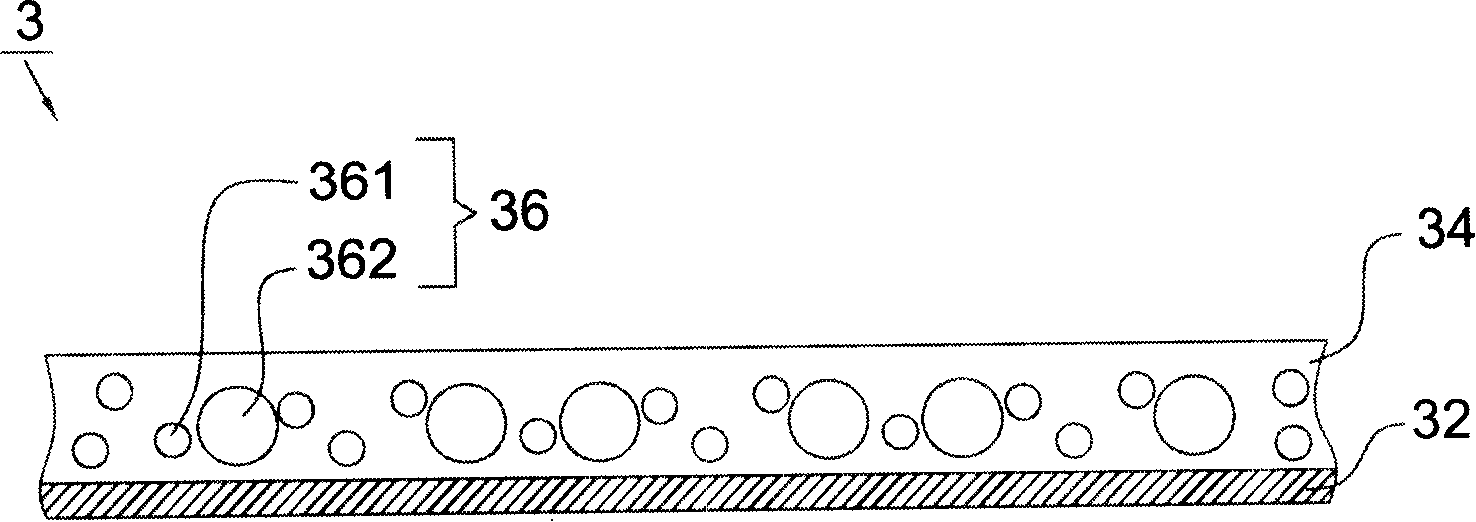

[0042] Such as Figure 3a As shown, the adhesive film (film) 3 of the first embodiment of the present invention is disclosed, which includes a removable base material 32 , a resin layer 34 and a plurality of arc-shaped elastic bodies 36 disposed in the resin layer 34 . The adhesive film 3 is used in the packaging process of the semiconductor chip as an adhesive material for the chip. The embodiment of this substrate 32 can be BT substrate (BT substrate) or adhesive tape (tape); When it is BT substrate, it can utilize epoxy resin (epoxy) to combine with this resin layer 34; When it is adhesive tape, It can be UV tape or blue tape, and it is flexible. The base material 32 is bonded with the resin layer 34 mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com