Electricity saver and method of making the same

A production method and technology for power saving, applied to electrical components, impedance networks, single-ended pair networks, etc., can solve problems such as poor power saving effect, poor power stability, and high reactive labor, and achieve simple and easy production conditions. Easy installation and use, basic investment and production investment and low working capital effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

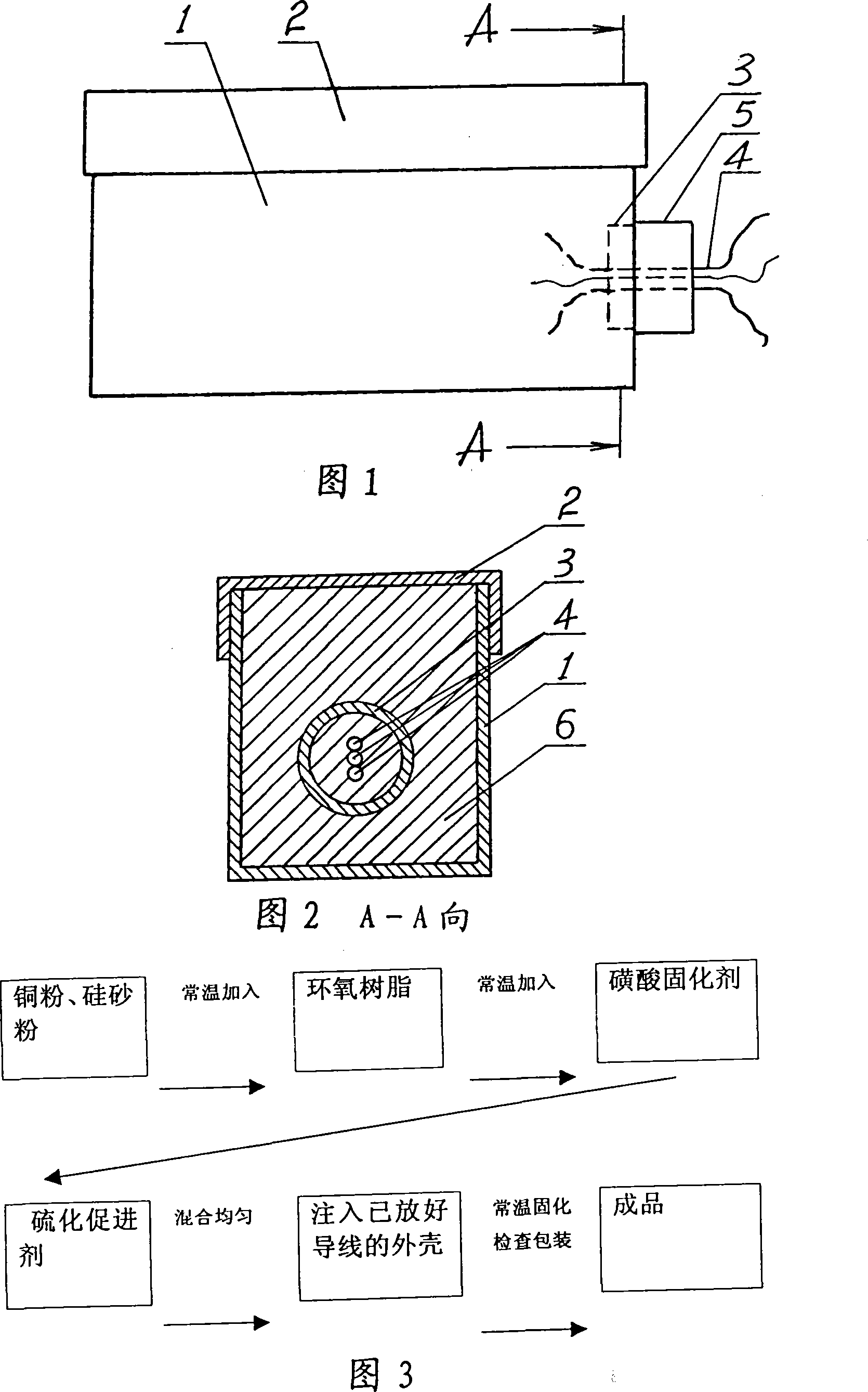

[0068] The manufacturing method of the power saver in the present invention will be described in detail below in conjunction with the accompanying drawings. As shown in Figure 3 of the manual:

[0069] The production method of the power saver and the production method of the present invention is: a production method of the power saver, according to the following steps:

[0070] (1), material preparation:

[0071] (1). ① Copper powder: 33.7% is 1.348 kg;

[0072] (1). ② Silica sand powder: 5.0% is 0.2 kg;

[0073] (1). ③. Epoxy resin: 60.5% is 2.42 kg;

[0074] (1). ④, sulfonic acid curing agent: 0.4% is 0.016 kg;

[0075] (1). ⑤, vulcanization accelerator: 0.4% is 0.016 kg;

[0076] The prepared raw materials are ready for use;

[0077] (2), mixing materials:

[0078] Put the copper powder and silica sand powder in the prepared raw materials into the epoxy resin, mix and stir evenly, then add the sulfonic acid curing agent and vulcanization accelerator in turn, mix and ...

specific Embodiment approach 3

[0084] Carry out by specific embodiment two, just determine corresponding concrete weight by following percentage respectively to " stocking up " of required raw material in operation step (1), namely:

[0085] The described preparation in operation step (1) is:

[0086] (1). ① Copper powder: 31.50% is 1.26 kg;

[0087] (1). ② Silica sand powder: 5.0% is 0.2 kg;

[0088] (1). ③. Epoxy resin: 62.5% is 2.5 kg;

[0089] (1). ④, sulfonic acid curing agent: 0.5% is 0.02 kg;

[0090] (1). ⑤, vulcanization accelerator: 0.5% is 0.02 kg.

specific Embodiment approach 4

[0091] Carry out by specific embodiment two, just determine corresponding concrete weight by following percentage respectively to " stocking up " of required raw material in operation step (1), namely:

[0092] The described preparation in operation step (1) is:

[0093] (1). ① Copper powder: 32% is 1.28 kg;

[0094] (1). ② Silica sand powder: 5.1% is 0.204 kg;

[0095] (1).③. Epoxy resin: 62.05% is 2.482 kg;

[0096] (1). ④, sulfonic acid curing agent: 0.41% is 0.0164 kg;

[0097] (1). ⑤, vulcanization accelerator: 0.44% is 0.0176 kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com