Method for producing weather-resistant laminates for encapsulating solar cell systems

A technology of solar cells and laminated materials, applied in the field of manufacturing photoelectric modules, can solve the problems of high cost and high energy consumption, etc.

Inactive Publication Date: 2008-06-18

ISOVOLTA OSTE ISOLIERSTOFFWERKE AG

View PDF3 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, these methods are energy-intensive and costly

[0005] Furthermore, due to their limited tensile strength, fluoropolymer films are only possible to manufacture in a certain minimum thickness

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

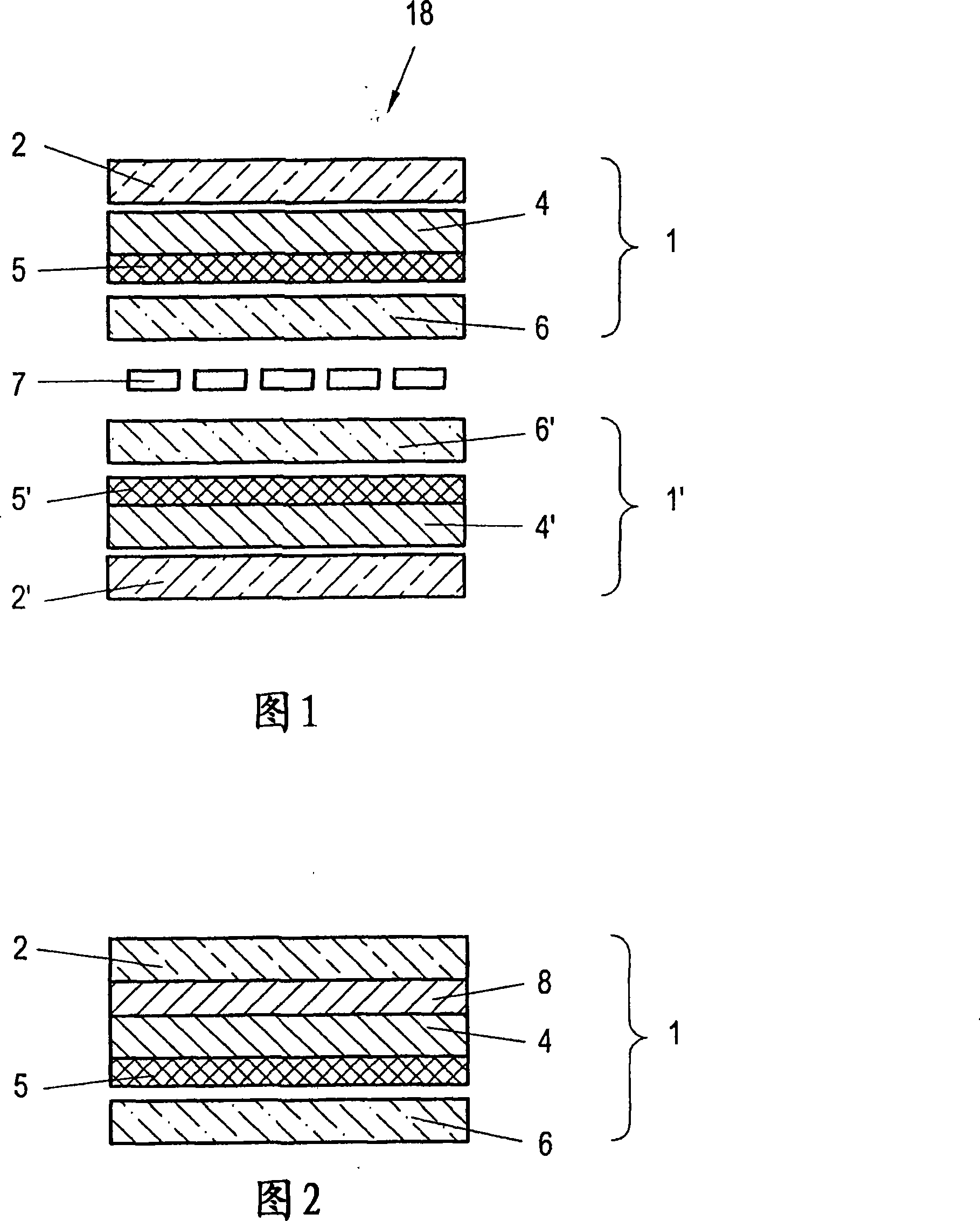

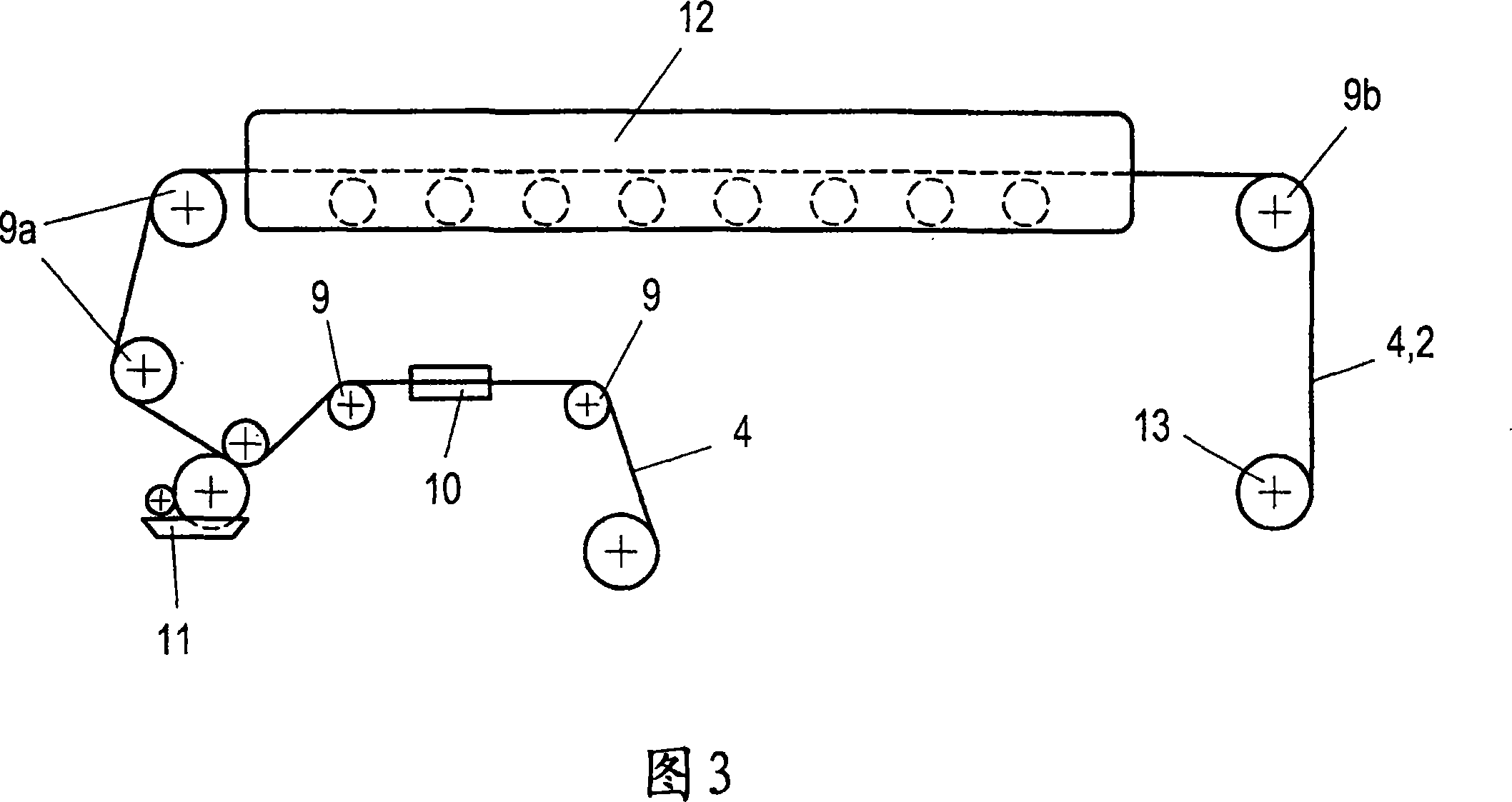

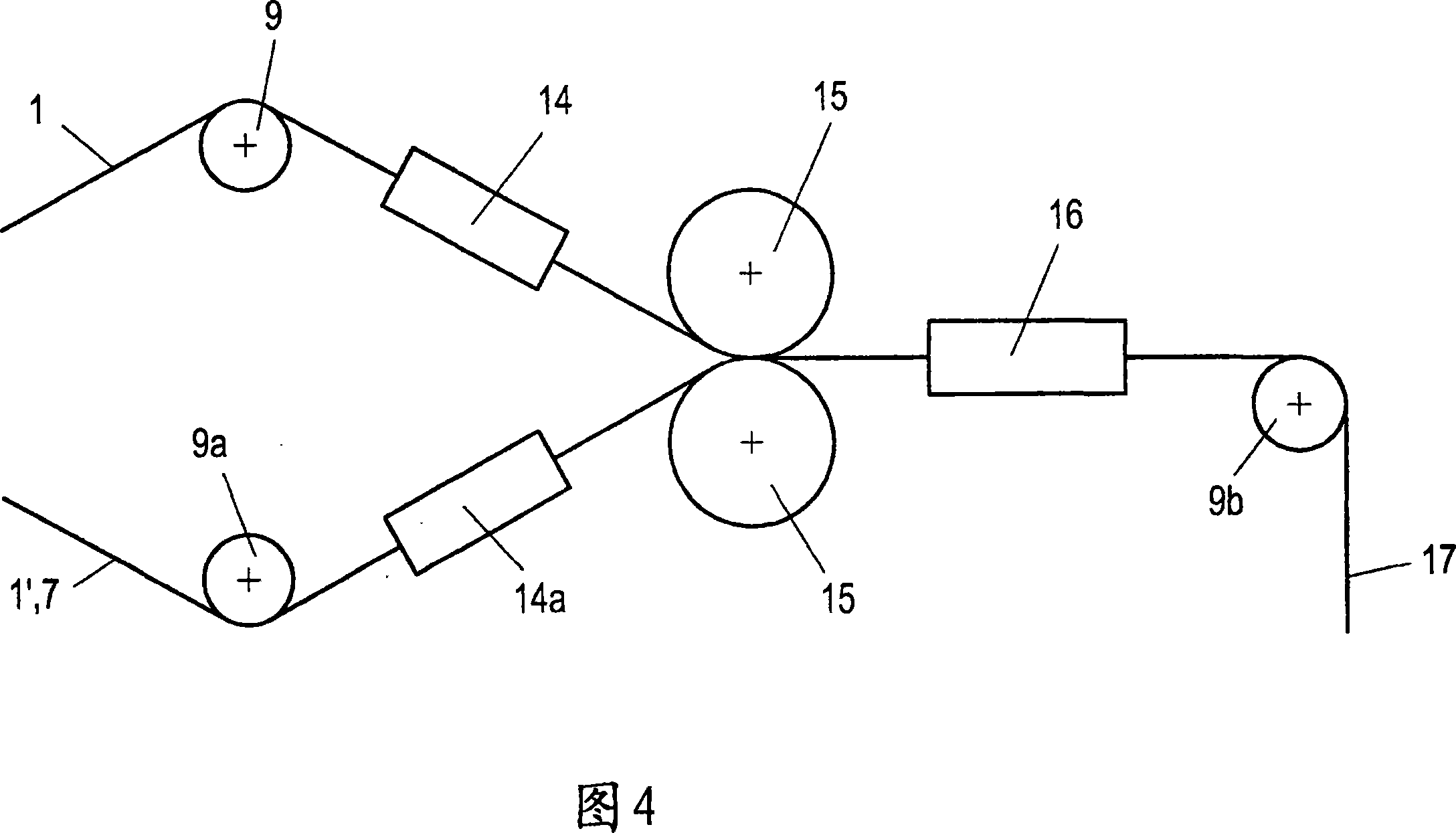

[0011] The invention is explained in more detail below on the basis of an exemplary description—see FIGS. 1 to 4—and possible embodiments.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a method for producing weather-resistant laminates (1, 1') for encapsulating solar cell systems (7). The inventive method is characterised in that at least one weather-resistant plastic layer (2, 2') is applied to a carrier material (4, 4'). The inventive coating method is advantageous in that the relatively expensive starting products, which are normally used in the form of films, can be reduced in the thickness and numbers thereof. The inventive laminate, which is produced according to said method, can be used in a plurality of ways due to the controllable adjustment of the layer thickness of the weather-resistant layer (2, 2'), in particular in connection with the finished photovoltaic modules. Said uses range from small energy plants for emergency telephones or camping cars to large-surfaced roof and faade systems and also large plants and solar power stations.

Description

technical field [0001] The invention relates to a method for the manufacture of a weather-resistant laminate for the encapsulation of solar cell systems and its use for the manufacture of photovoltaic modules (photovoltaischer modules). Background technique [0002] Photovoltaic modules are used to generate electricity from sunlight and consist of laminated materials which contain a solar cell system, for example a silicon solar cell, as a core layer. The core is encapsulated with an encapsulation material to ensure protection against mechanical and climate-induced influences. These materials can consist of one or more layers made of glass and / or plastic film and / or plastic film composites. [0003] Processes for the manufacture of weatherable film laminates for photovoltaic cell encapsulation are known from WO-A-94 / 29106, WO-A-01 / 67523 and WO-A-00 / 02257. In these modules, the solar cell system must not only be protected against mechanical damage, but also against water va...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B32B27/00H01L31/00C08J7/04

CPCY10T428/264Y10T428/3154Y02B10/10Y10T428/31551Y10T156/10B32B27/06Y02E10/50Y10T428/31786H01L31/048Y02B10/12C08J7/043

Inventor N·德皮内J·丹尼尔科

Owner ISOVOLTA OSTE ISOLIERSTOFFWERKE AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com