Pole-shaped radiator with thermal fin

A heat sink and heat sink technology, which is applied in the direction of heat exchanger types, indirect heat exchangers, tubular elements, etc., can solve the problems of unsatisfactory heat dissipation power, large volume, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

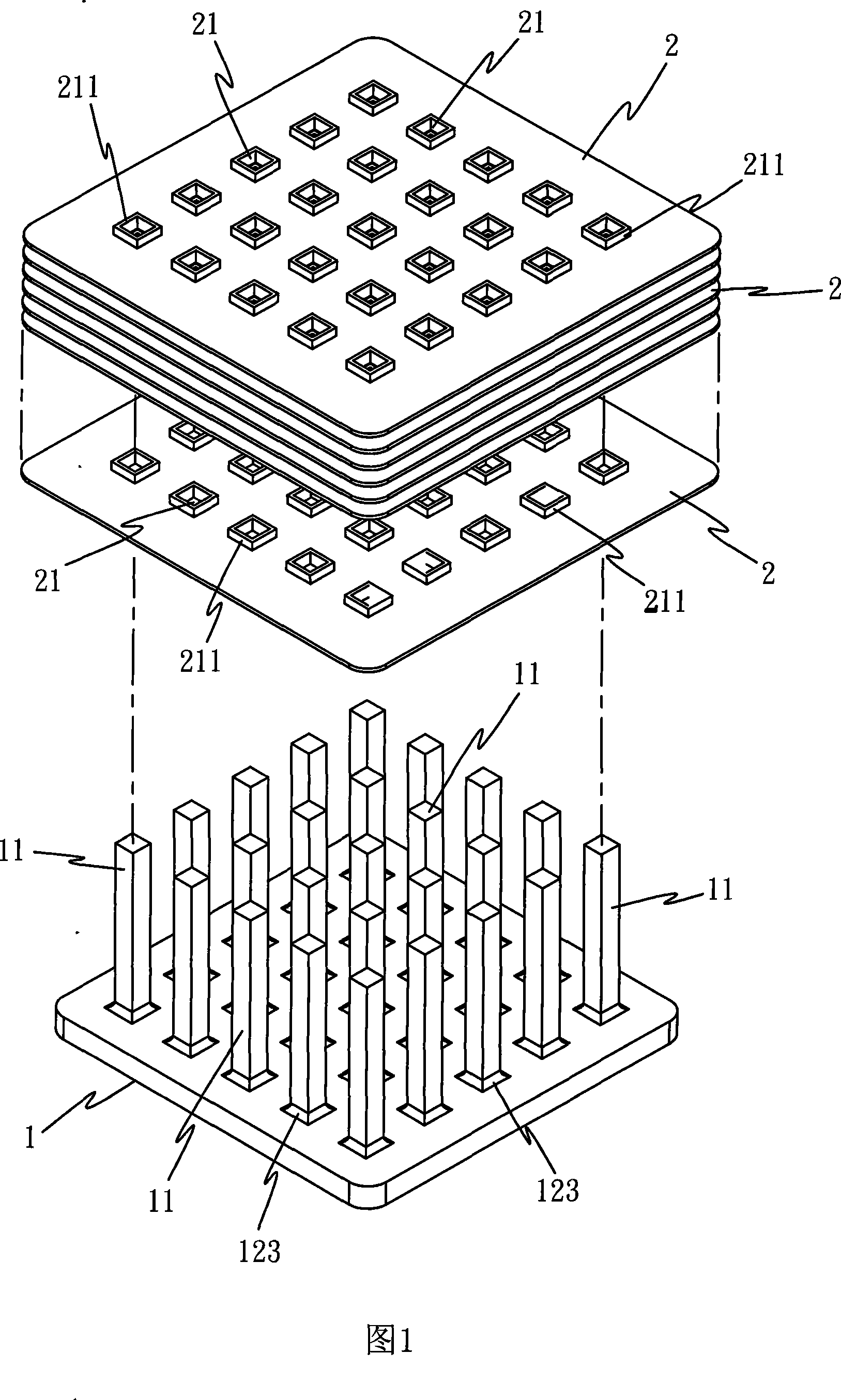

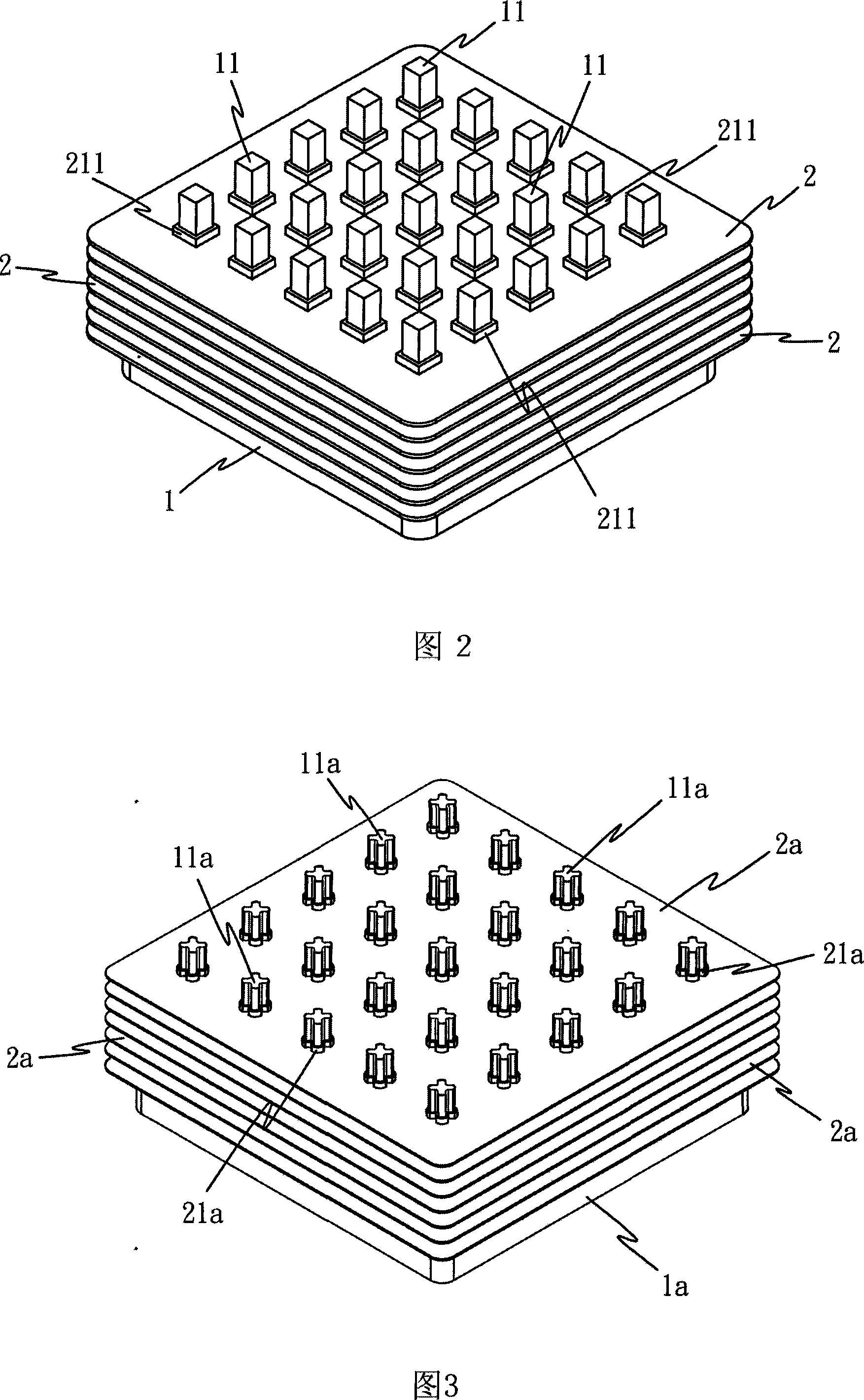

[0049] As shown in Figures 1 and 2, the design of the present invention is a "columnar radiator with cooling fins", which mainly includes a base 1 and a plurality of cooling fins 2, wherein:

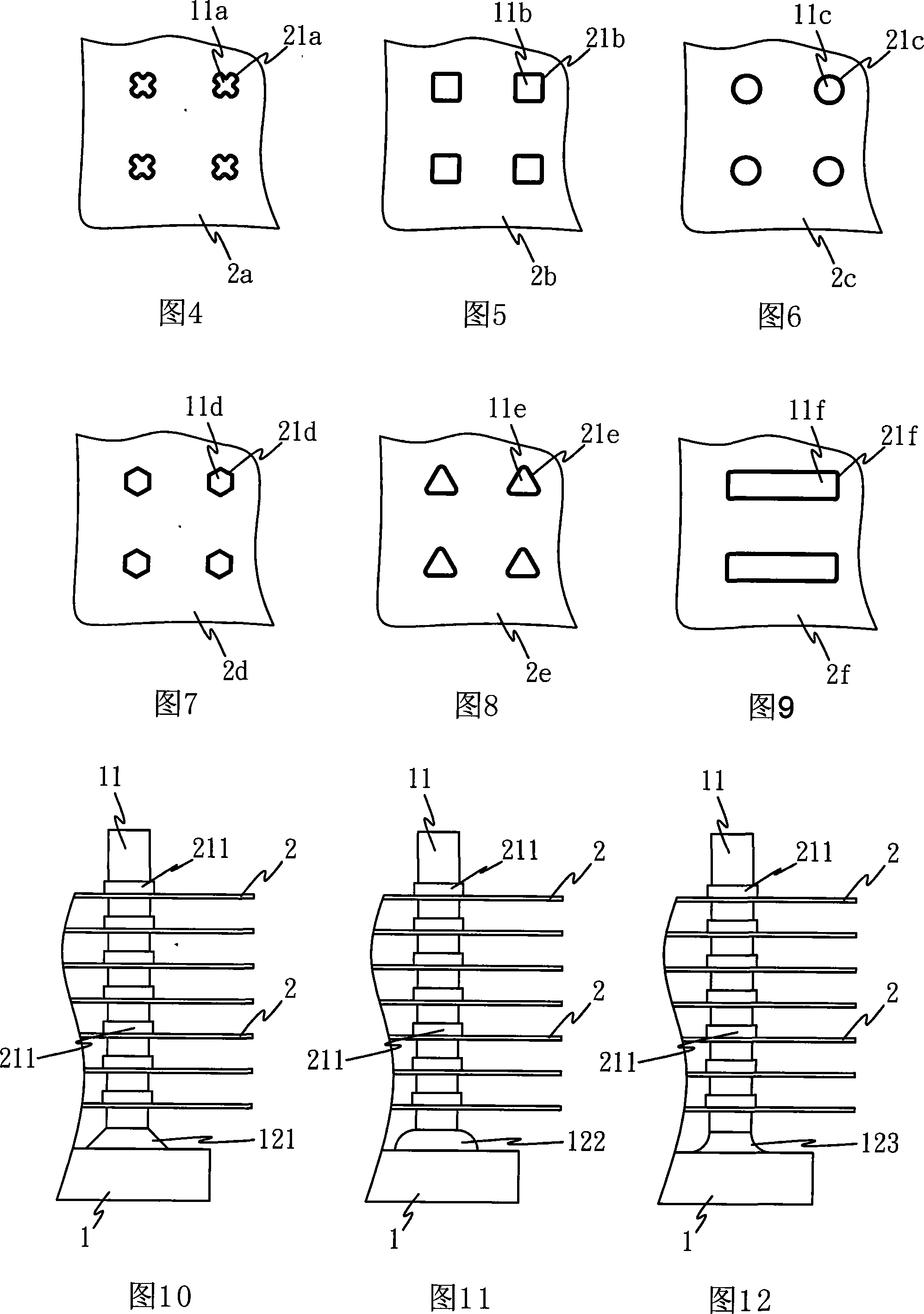

[0050] The base 1 is a metal base with good thermal conductivity (such as aluminum or copper metal, commonly known as aluminum base or copper base). Columns 11, each heat dissipation column 11 can be arranged in regular or irregular adjacent intervals, and the heat dissipation columns 11 shown in the embodiment figure are arranged in a regular matrix form;

[0051] A plurality of cooling fins 2 have a plurality of openings 21 corresponding to the above-mentioned cooling columns 11, so that the openings 21 can fit into the cooling columns 11 and combine with the base 1, and utilize the tightness between the openings 21 and the cooling columns 11. Matching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com