Method and device for optimization of flatness control in the rolling of a strip

A flatness and strip technology, applied in metal rolling, measuring devices, profile control, etc., can solve the problems of different flatness control methods in cold rolling mills, and achieve the effect of reducing scrap and improving the output of rolling mills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

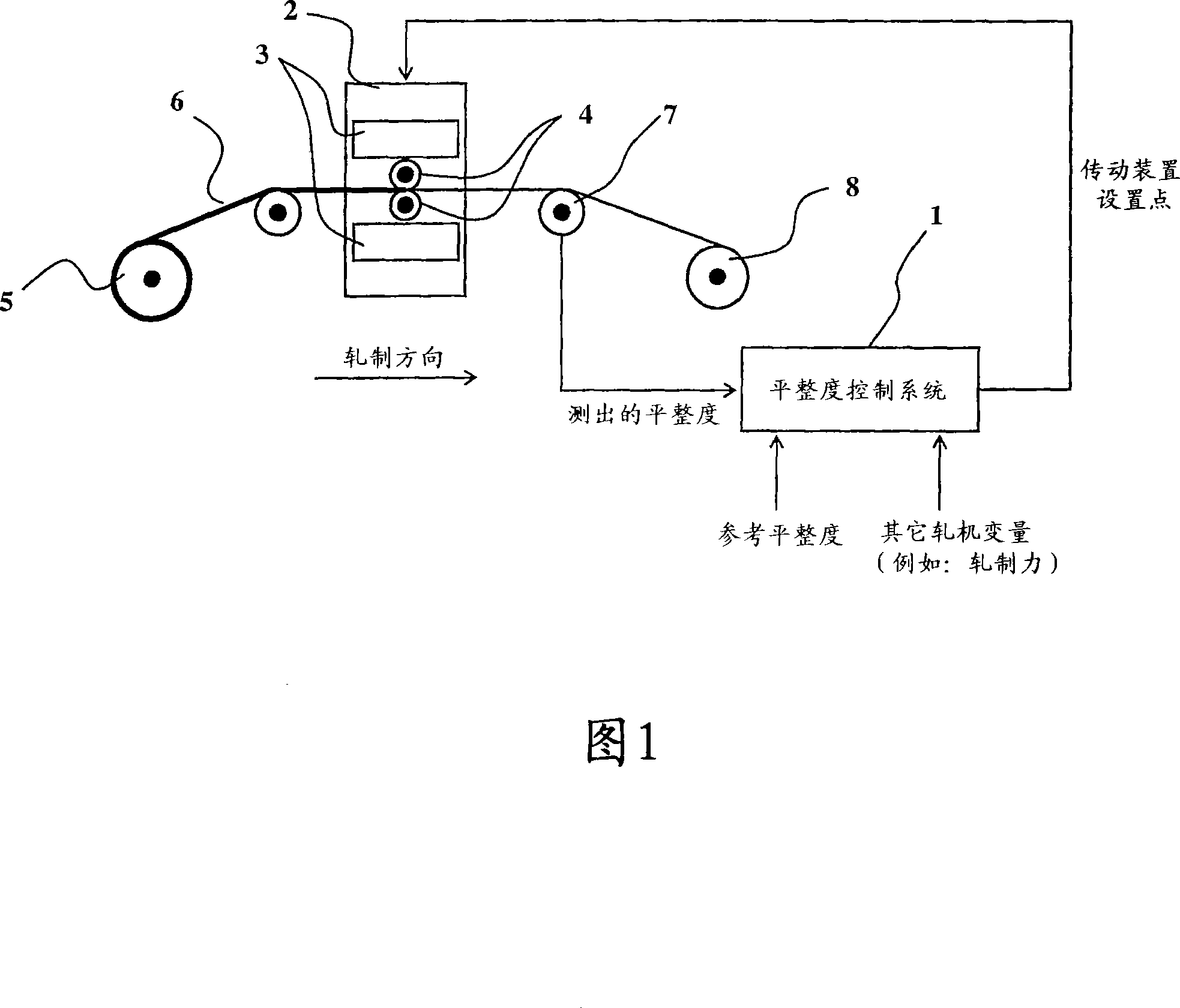

[0040]As shown in FIG. 1 , a flatness control system 1 is integrated in a system comprising a rolling mill stand 2 with several transmissions 3 and rolls 4 . The uncoiler 5 supplies the strip 6 to the rolling stand 2 and passes the strip 6 through the rolling stand 2, whereby the strip 6 passes through a flatness measuring device 7 or a tension detection device, such as a "Stressometer", and Winding machine 8 is rolled up. The mill stand can control the inclination, bending and / or displacement of the rolls 4 . The end product of this rolling process is a rolled strip 6 with the desired flatness.

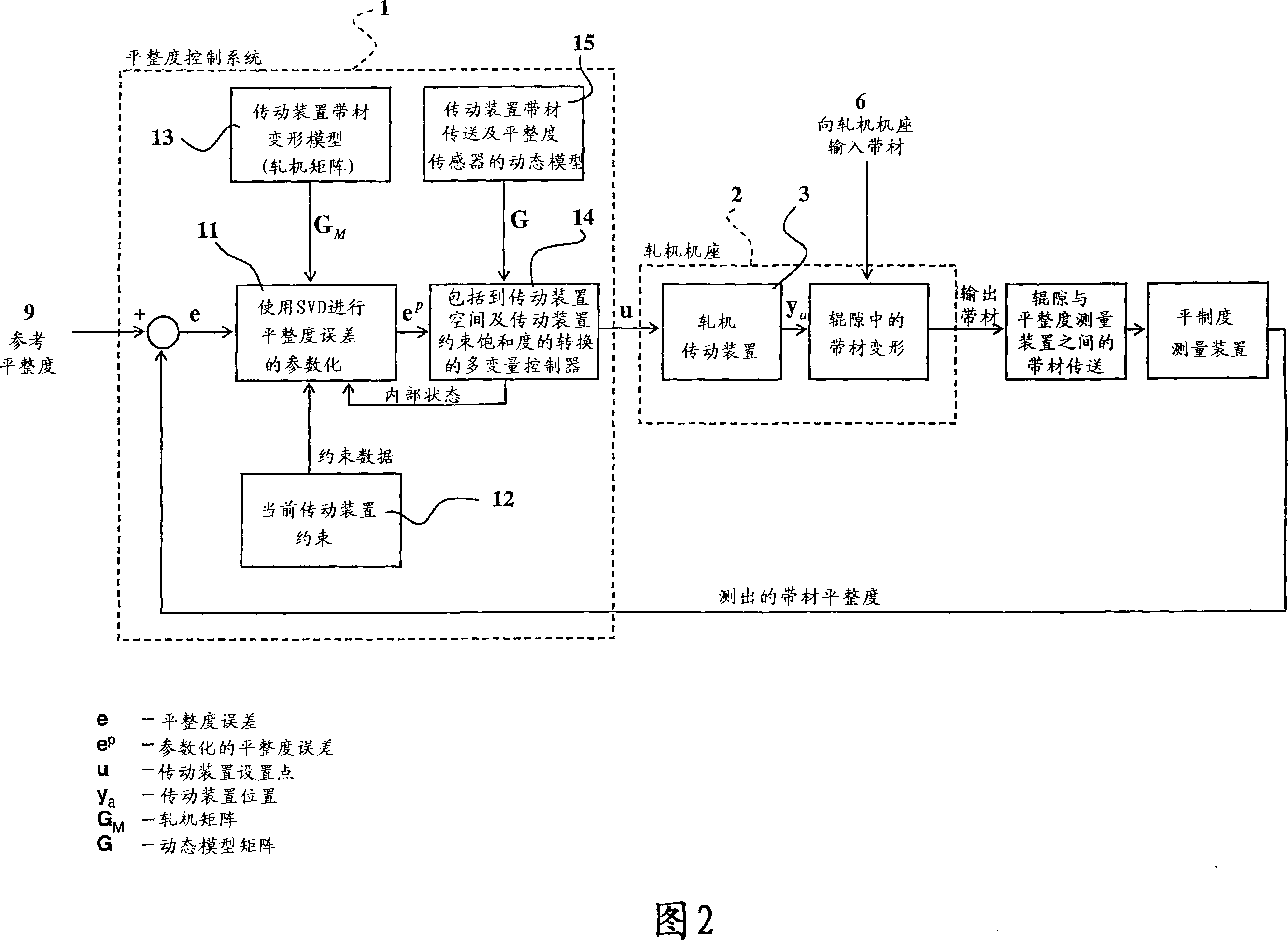

[0041] As can be seen in Figure 2, the flatness control system 1 is designed around a number of front-facing building blocks having all the required functions.

[0042] The reference flatness 9 is compared with the measured strip flatness in a comparator 10 . The resulting flatness error e is supplied to a flatness error parameterization unit 11, and a signal from a first unit 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com