Method of producing concentrated liquid dairy products

A technology for concentrated milk and dairy products, applied in the field of preparing concentrated liquid dairy products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

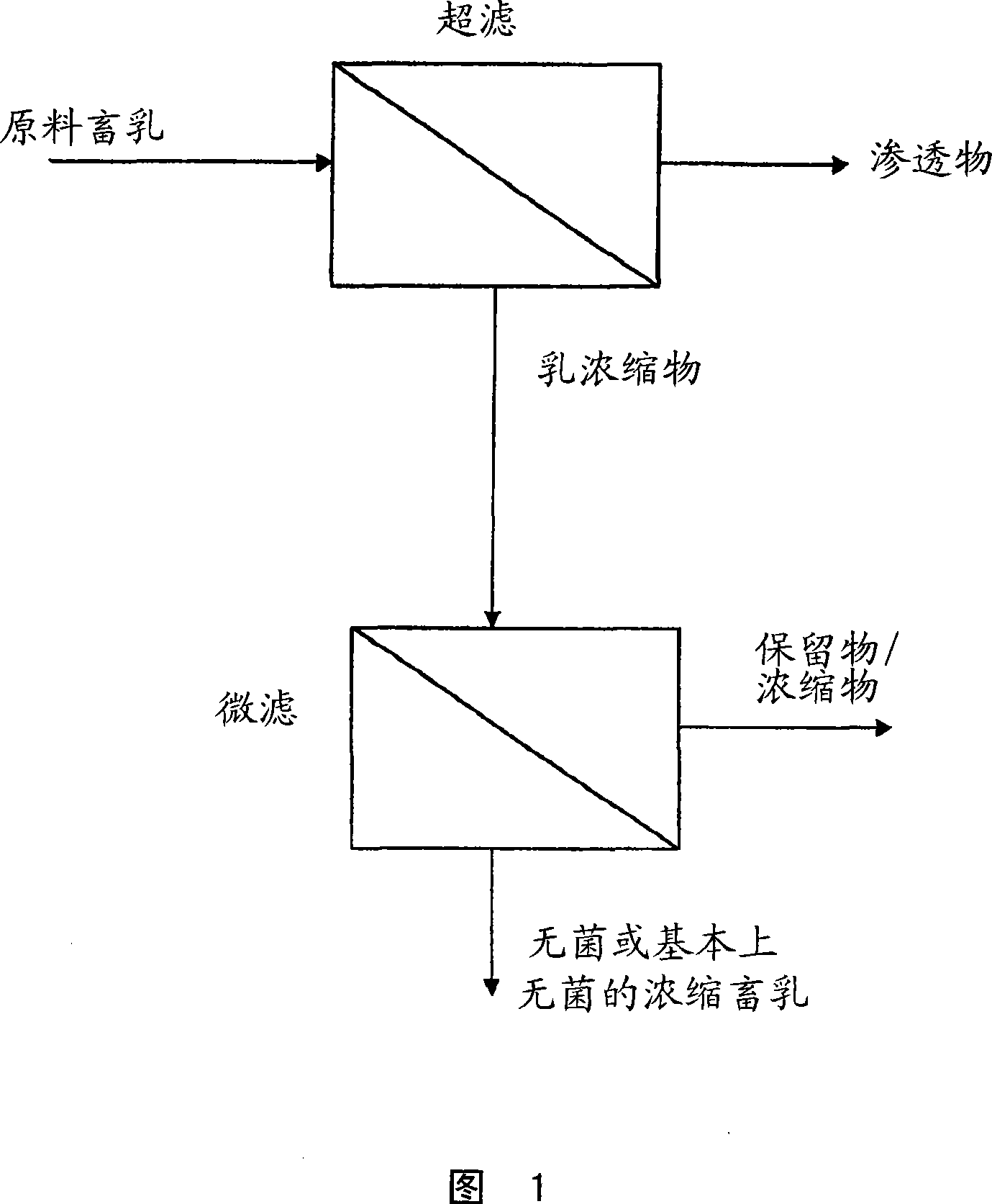

Image

Examples

Embodiment 1

[0040] Example 1. Concentration of skim milk (Elgin Diary, Illinois) at 120°F (about 3.2% protein, about 2.5% lactose and less than about 0.1% fat) to produce about 4.4X dairy concentrate / retentate with about 14% protein, 1.5% lactose and 2% fat. Ultrafiltration was performed at 25-35 psig and 115-125°F. After ultrafiltration, the dairy concentrate has about 1.2 x 10 4 Colony forming units per gram (cfu / g) of microbial spores.

[0041] The 4.4X dairy concentrate was then passed through a microfiltration membrane (Membralox Filter, Pall Company, New York) having an average pore size of about 1.4 microns at about 120[deg.]F and 20-30 psig. About 80 lbs of dairy concentrate was filtered using microfiltration membranes to obtain about 75 lbs of permeate (sterile concentrated milk) and about 5 lbs of retentate. The permeate has about 14% protein, about 1.5% lactose, and about 2% fat, making about a 4.4x milk concentrate (ie, 14% protein in concentrate divided by 3.2% protein in ...

Embodiment 2

[0043] Example 2. Concentrate skim milk in the manner provided in Example 1. Microbial contamination levels were measured before and after microfiltration using the procedure of Example 1. The results are shown in Table 3 below. This result demonstrates that milk concentration prior to microfiltration forms concentrated milk that does not require significant heat treatment prior to subsequent use.

[0044] table 3

[0045] sample

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com