Coating type particle composite fertilizer and producing technique thereof

A compound fertilizer and granule technology, applied in the direction of urea compound fertilizer, fertilizer form, inorganic fertilizer, etc., can solve the problems of fertilizer incompatibility, achieve the effect of improving utilization rate, reducing environmental pollution, and reducing the comprehensive cost of fertilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

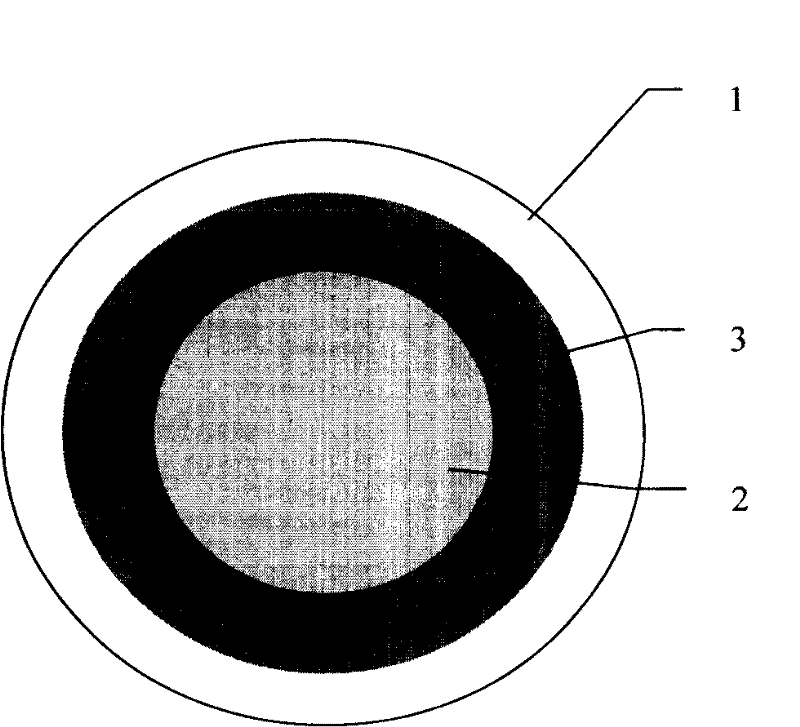

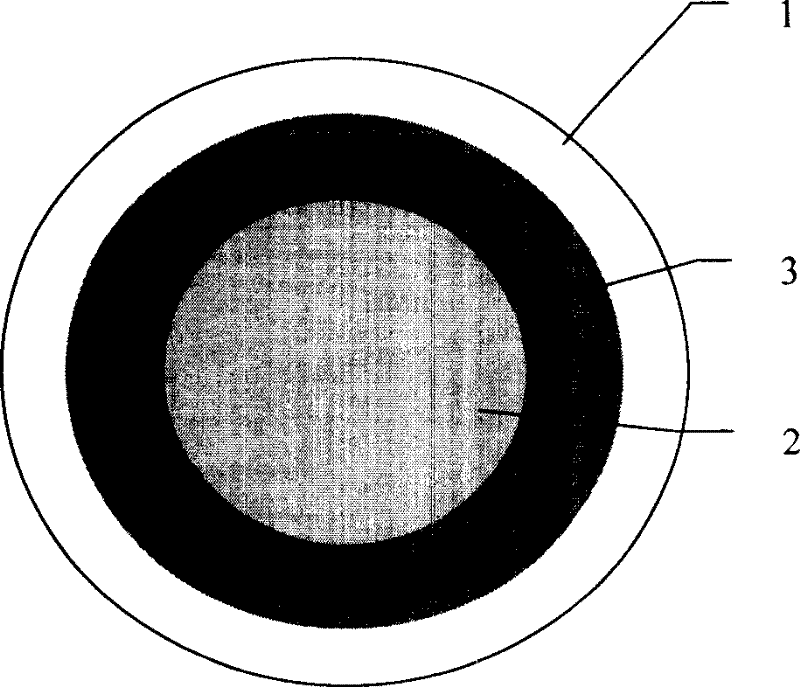

[0024] Embodiment 1: adopt common compound fertilizer granule as inner core (2), with the urea slurry that contains at least 30% by weight with inner core (2) surface through once spray coating, compact coating layer (3); Or the second The second coating is to form a coating layer, or the third coating is to form a coating layer, and so on, multi-layer coatings can be used, and the coating is sprayed for the last time to form the outermost dense coating layer (1). After coating, it is dried and cooled, and then the surface of the shell of the finished product is polished, rounded and anti-hardening sprayed to obtain the product.

[0025] A coated granular compound fertilizer, the coating material is urea, the slurry concentration is 90% by mass; the product has a core diameter of φ1.0mm-φ3.9mm and a fertilizer slurry with a thickness of 0.1mm-1.5mm The outer shell is composed of an obvious color difference between the inner core and the outer coating layer; the surface of the ...

Embodiment 2

[0026] Embodiment 2: A kind of coated granular compound fertilizer, its coating material is urea, and its slurry concentration is 97% by mass percentage; Product diameter is the core of φ1.0mm-φ3.9mm and thickness is 0.1mm-1.5mm The shell of the fertilizer slurry is composed of an obvious color difference between the inner core and the outer coating layer; the surface of the fertilizer granule shell is polished and sprayed with an anti-plate agent, and the diameter of the finished particle is between φ1.8mm-φ4.75mm; the surface is relatively smooth Round, shiny and transparent. The production process is as follows: select the inner core with a product diameter of φ1.0mm-φ3.9mm, spray urea with a slurry concentration of 97% by mass on it, and the temperature of the urea slurry is about 120-135°C. After cooling, it crystallizes in Outside the inner core, a coated compound fertilizer with obvious inner and outer layers is formed.

Embodiment 3

[0027] Embodiment 3: a kind of coated granular compound fertilizer, its coating material is urea, and its slurry concentration is 80% by mass percentage; Product diameter is the core of φ1.0mm-φ3.6mm and thickness is 0.1mm-1.5mm The shell of the fertilizer slurry is composed of an obvious color difference between the inner core and the outer coating layer; the surface of the fertilizer granule shell is polished and sprayed with an anti-plate agent, and the diameter of the finished particle is between φ1.8mm-φ4.75mm; the surface is relatively smooth Round, shiny and transparent. The production process is as follows: select the inner core with a product diameter of φ1.0mm-φ3.9mm, spray urea with a slurry concentration of 80% by mass on it, and the temperature of the urea slurry is about 100-125°C. After cooling, it crystallizes in Outside the inner core, a coated compound fertilizer with obvious inner and outer layers is formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com