Novel distributed anaerobic treatment equipment

An anaerobic treatment equipment and decentralized technology, applied in the field of water treatment, can solve the problems of long construction period, easy corrosion of steel bars, high manufacturing costs, etc., and achieve the effect of lightweight products, strong biological adhesion, and economical and reliable equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

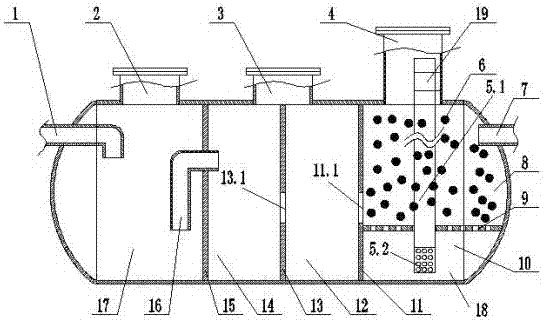

[0020] Embodiment 1: A new type of decentralized anaerobic treatment equipment, including a horizontal shell, a water inlet 1 opened at the left end of the horizontal shell, a water outlet 7 opened at the right end of the horizontal shell, and set in the horizontal shell The three bulkheads are the first, second, and third bulkheads (15, 13, 11) from left to right, and the three bulkheads divide the horizontal shell into four from left to right. The chambers respectively constitute anaerobic zone I 17 (first chamber), anaerobic zone II 14 (second chamber), anaerobic zone III 12 (third chamber), aerobic precipitation zone 18 (fourth chamber) room), the first manhole 2 is opened at the top shell position of the first chamber, the second manhole 3 is opened at the top shell position of the second bulkhead 13 between the second and third chambers, and the fourth A third manhole 4 is provided at the top shell of the chamber, a diversion pipe 16 is provided on the first bulkhead 15,...

Embodiment 2

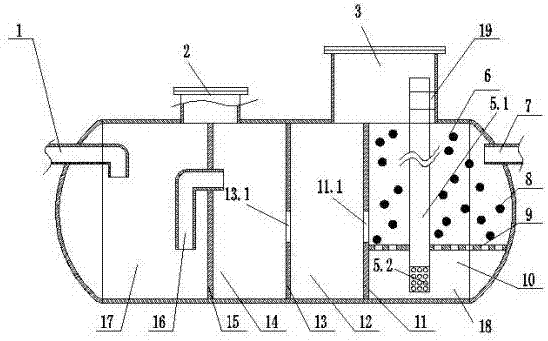

[0021] Embodiment 2: Referring to Embodiment 1, a first manhole 2 is provided at the top shell position of the first bulkhead 15 in the middle of the first and second chambers, and the third bulkhead in the middle of the third and fourth chambers 11 A second manhole 3 is provided at the upper top shell position.

Embodiment 3

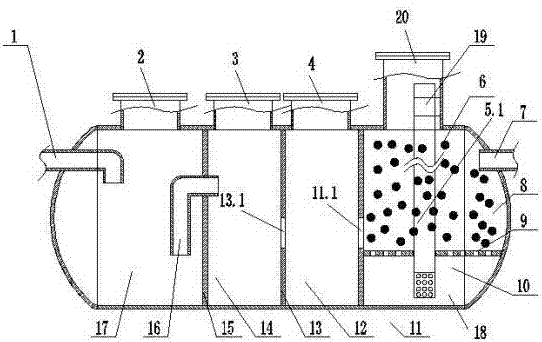

[0022] Embodiment 3: Referring to Embodiment 1, a first manhole 2 is provided at the top shell position of the first chamber, a second manhole 3 is opened at the top shell position of the second chamber, and a top shell of the third chamber is provided. A third manhole 4 is opened at the body position, and a fourth manhole 20 is opened at the top shell position of the fourth chamber.

[0023] In the above-mentioned embodiment 1 or 2 or 3, the main body of a new type of distributed anaerobic treatment equipment is integrated injection molding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com